Dust removal protection mechanism of environment-friendly ground grinding equipment for building

It is a protective mechanism and environment-friendly technology, which is applied in the direction of machine tools, grinding/polishing equipment, and mechanical equipment suitable for grinding workpiece planes. It can solve the problems of grinding disc damage, long grinding time, and large water spray volume. The effect of reducing volume, increasing contact area, and preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

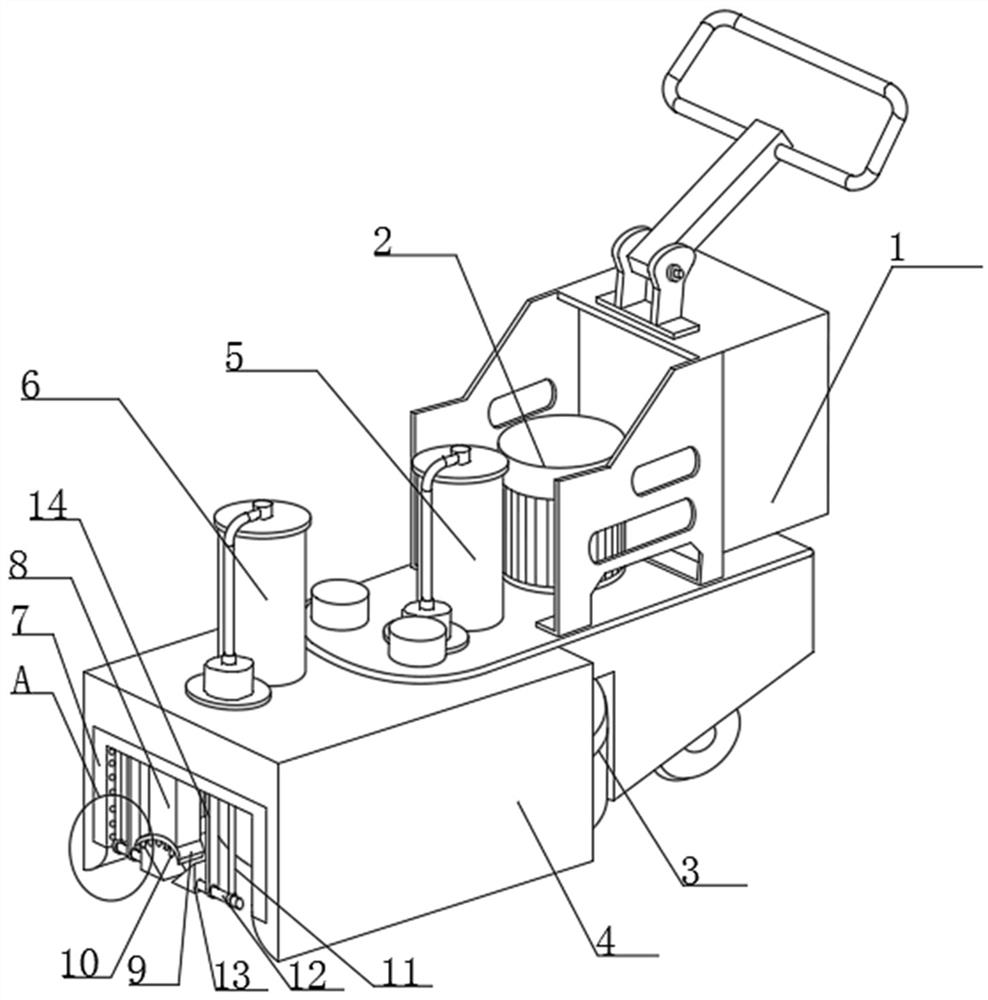

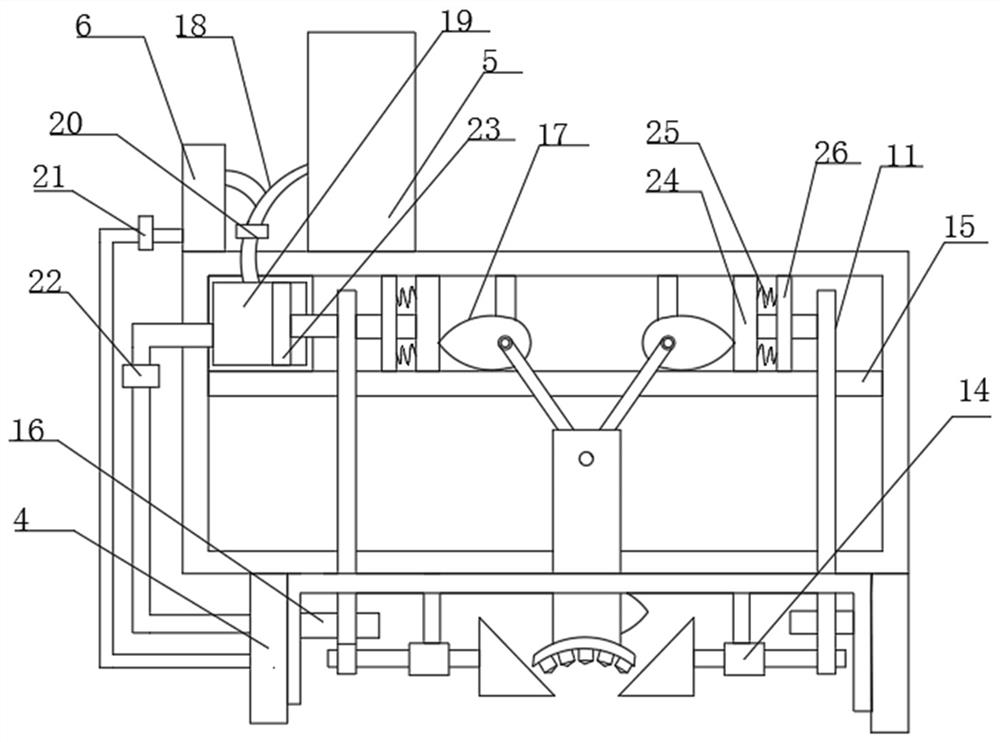

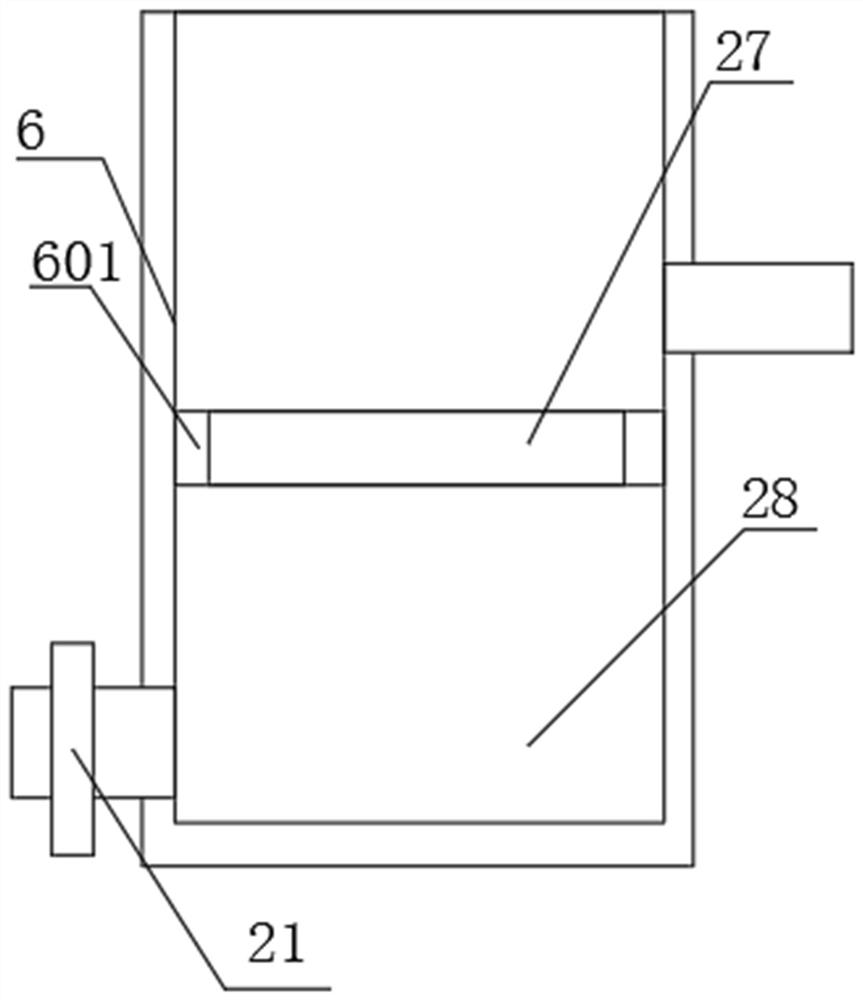

[0035] Such as Figure 1-7 As shown, an environment-friendly ground grinding equipment for construction, including a grinding equipment body (1), a grinding motor (2), a grinding sleeve (3), a grinding sheet (29) and a dust removal protection mechanism. The dust removal protection mechanism includes The protective casing (4) on the outside of the sleeve (3), the water curtain injection frame (7) is fixedly installed on the inner edge of the input end of the protective casing (4), and the middle part of the protective casing (4) is slidingly connected with a push rod (8 ), the grinding motor (2) drives the push rod (8) to move up and down, the middle part of the protective shell (4) and the two sides of the push rod (8) are slidingly connected with side cutting blades (13), and the push rod (8) The downward movement drives the two side cutting blades (13) to move towards each other. The cleaning agent nozzle (16) is fixedly installed on the inner side of the protective housing ...

Embodiment 2

[0043] Such as Figure 1-7 As shown, an environment-friendly ground grinding equipment for construction, including a grinding equipment body (1), a grinding motor (2), a grinding sleeve (3), a grinding sheet (29) and a dust removal protection mechanism. The dust removal protection mechanism includes The protective casing (4) on the outside of the sleeve (3), the water curtain injection frame (7) is fixedly installed on the inner edge of the input end of the protective casing (4), and the middle part of the protective casing (4) is slidingly connected with a push rod (8 ), the grinding motor (2) drives the push rod (8) to move up and down, the middle part of the protective shell (4) and the two sides of the push rod (8) are slidingly connected with side cutting blades (13), and the push rod (8) The downward movement drives the two side cutting blades (13) to move towards each other. The cleaning agent nozzle (16) is fixedly installed on the inner side of the protective housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com