Atmospheric superconductive heating furnace

A heating furnace and superconducting technology, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large media loss, large safety hazards, high costs, etc., to improve pressure resistance and reduce Hazardous, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

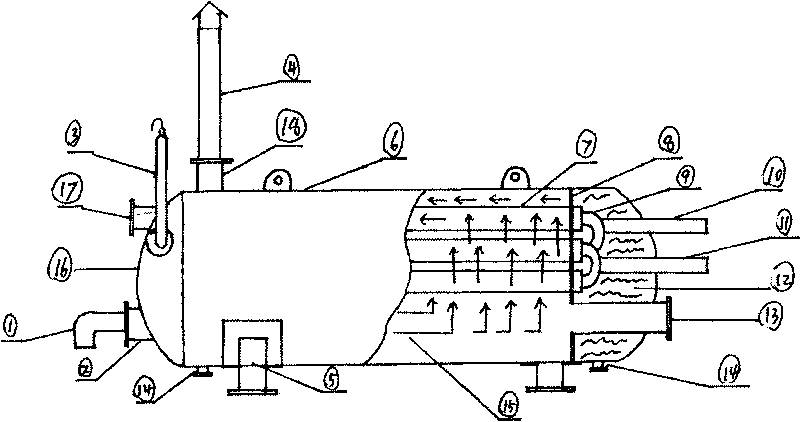

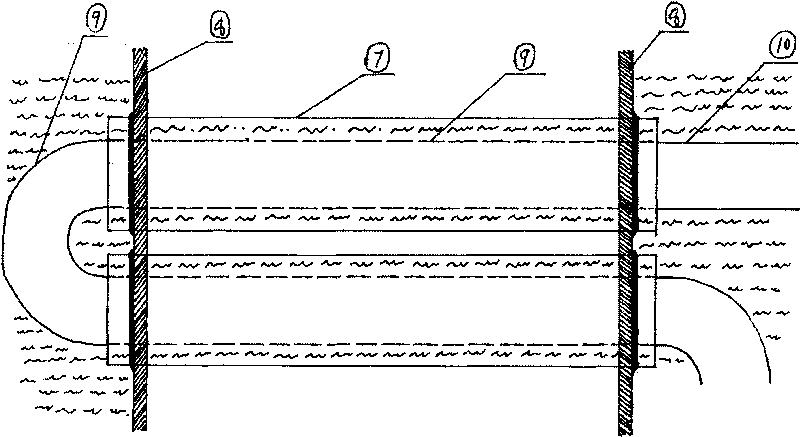

Embodiment 1

[0023] Embodiment 1, with reference to attached figure 1 and 2 , the present invention mainly consists of a casing 6, a head 16, a superconducting sleeve 7, a serpentine coil 9, a sealing support flower plate 8, an oil and gas inlet and outlet 10, a hot water inlet and outlet 11, a burner 1, a fire tube 2, an explosion-proof Port 13, chimney 4, smoke box 18, support 5, breathing water seal liquid level gauge 3, sewage outlet 14, cleaning port 17, the bottom of the inner cavity of the housing 6 is provided with a fire tube 2 and an explosion-proof port 13, the fire tube 2. Connect the chimney 4 through the wet smoke box 18. The smoke box 18 is set on the top of the water chamber cavity 12. The cleaning port 17 passes through the head 16 and communicates with the smoke box 18. The water chamber cavity 12 is supported by the seal between the flower plate 8 and the head 16. space between. The lower part of the inner cavity of the shell is a radiation convection chamber 15, and t...

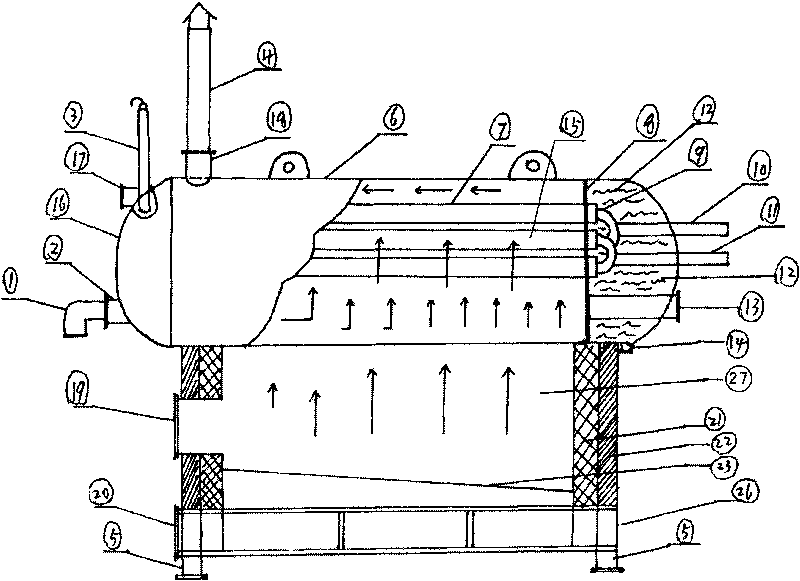

Embodiment 2

[0028] Embodiment 2: with reference to attached image 3 and 4 , The other structure of this product is the same as the first embodiment above, the difference is that a coal combustion chamber is added at the bottom of the shell 6 . The coal-fired chamber consists of a bracket 26, a support 5, a coal inlet 19, an air-regulating and slag-clearing port 20, a refractory layer 21, an insulation layer 22, a grate 23, a coal-fired radiation chamber 27, a coal-inlet door 24, an air-adjusting and slag-clearing Door 25 is formed.

[0029] The housing 6 is integrally positioned on the upper part of the coal combustion chamber. The bottom of the casing 6 is open, so that the radiation convection chamber 15 and the coal-fired radiation chamber 27 are integrated to form a complete coal and gas dual-purpose superconducting heating furnace.

[0030] The working principle of this heating furnace is basically the same as that of Embodiment 1, the difference is that the fuel coal (the fuel g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com