A strong discharge pump structure and a cleaning machine using the strong discharge pump structure

A technology for drainage chambers and drainage pipes, which is applied in liquid cleaning methods, pumps, pump control, etc. It can solve problems such as residual water odor, water residue, and box corrosion, so as to improve the pressure sensing accuracy and service life. , the effect of reducing the amount of residual water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

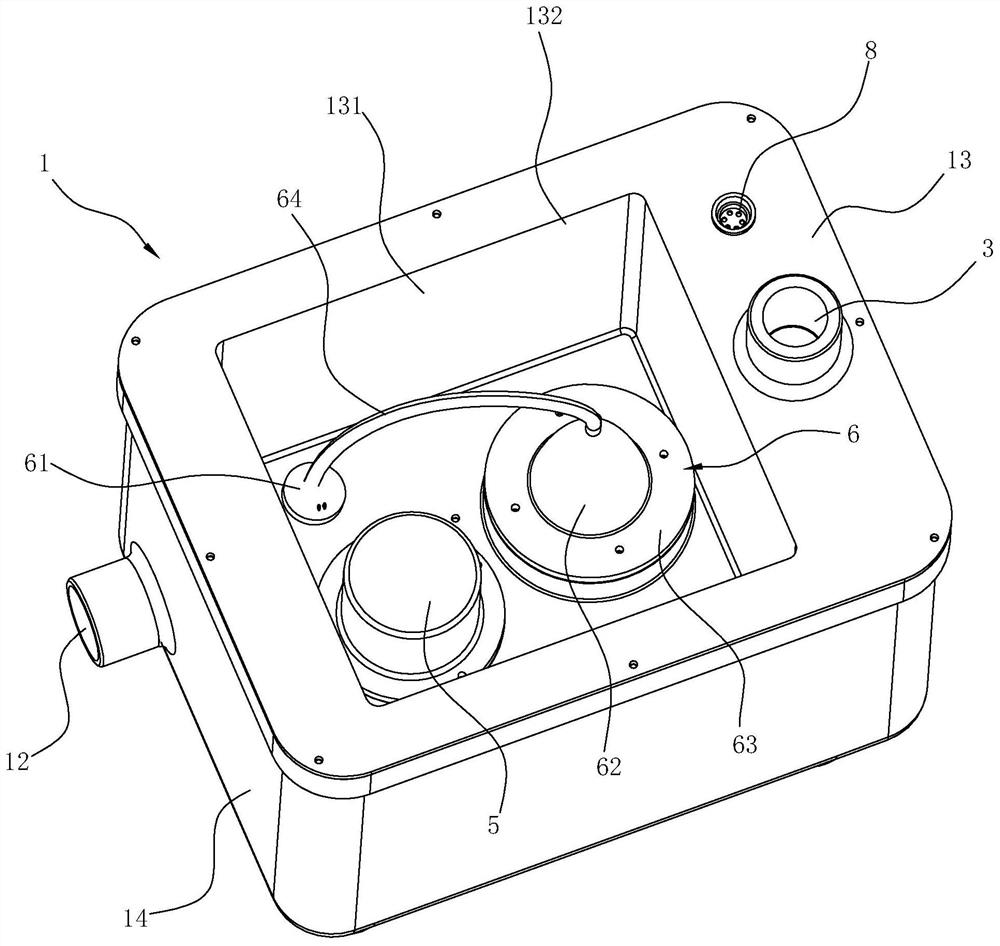

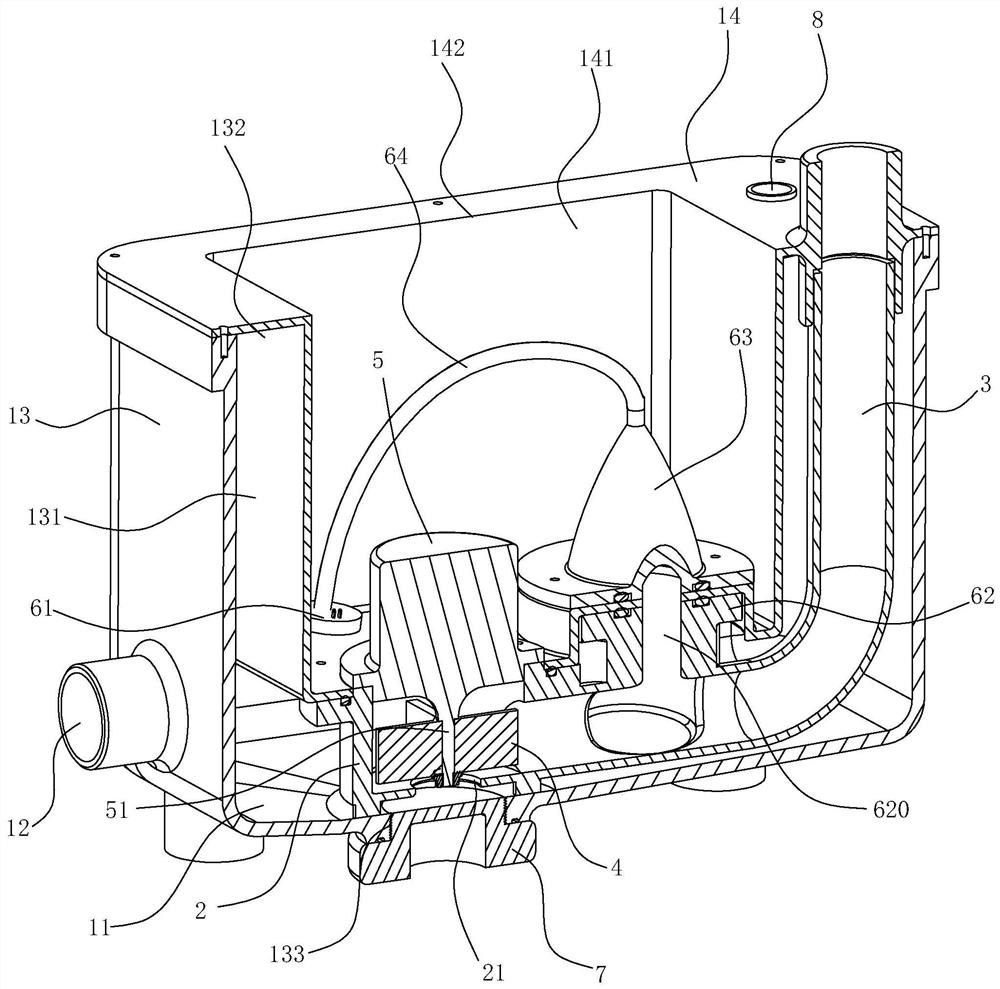

[0033] Such as Figure 1~4 As shown, the strong discharge pump junction of this embodiment includes a body 1, a volute 2, a drain pipe 3, an impeller 4, a driving member 5, and a pressure assembly 6. The interior of the body 1 is hollow to form a drainage chamber 11 with a U-shaped cross section. A first water inlet 12 for supplying water into the drain cavity 11 is opened on the side wall of 1 . The volute 2 is arranged in the drain chamber 11 , and the bottom of the volute 2 is provided with a second water inlet 21 communicating with the drain chamber 11 , and the second water inlet 21 is arranged close to the inner bottom wall of the drain chamber 11 . The drain pipe 3 is arranged in the drain cavity 11 , the first end of the drain pipe 3 communicates with the volute 2 , and the second end of the drain pipe 3 extends out of the body 1 . The impeller 4 is a centrifugal impeller, and the impeller 4 is rotatably arranged in the volute 2 and used for pumping out the water in t...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the connection position and connection method of the pressure assembly 6' and the volute 2' are different.

[0042] Such as Figure 5 As shown, specifically, the bottom of the housing 62' in this embodiment is connected with an air channel 65' that can communicate the pressure chamber 620' with the volute 2', and the first end of the air channel 65' is connected to the pressure chamber 620' The bottom of the air passage 65' communicates with the side of the volute 2', and the air passage 65' extends downward gradually from the first end to the second end. This structure is beneficial to prevent a large amount of water from entering the pressure chamber 620' and then rushing into the air pipe 64'.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com