Comprehensive automatic control system for lubricating oil pump station oil supply pressure and oil supply temperature

An automatic control system and oil supply temperature technology, applied in lubricating parts, engine temperature, engine lubrication, etc., can solve problems such as inability to perform dynamic real-time adjustment, inapplicability, and low oil supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

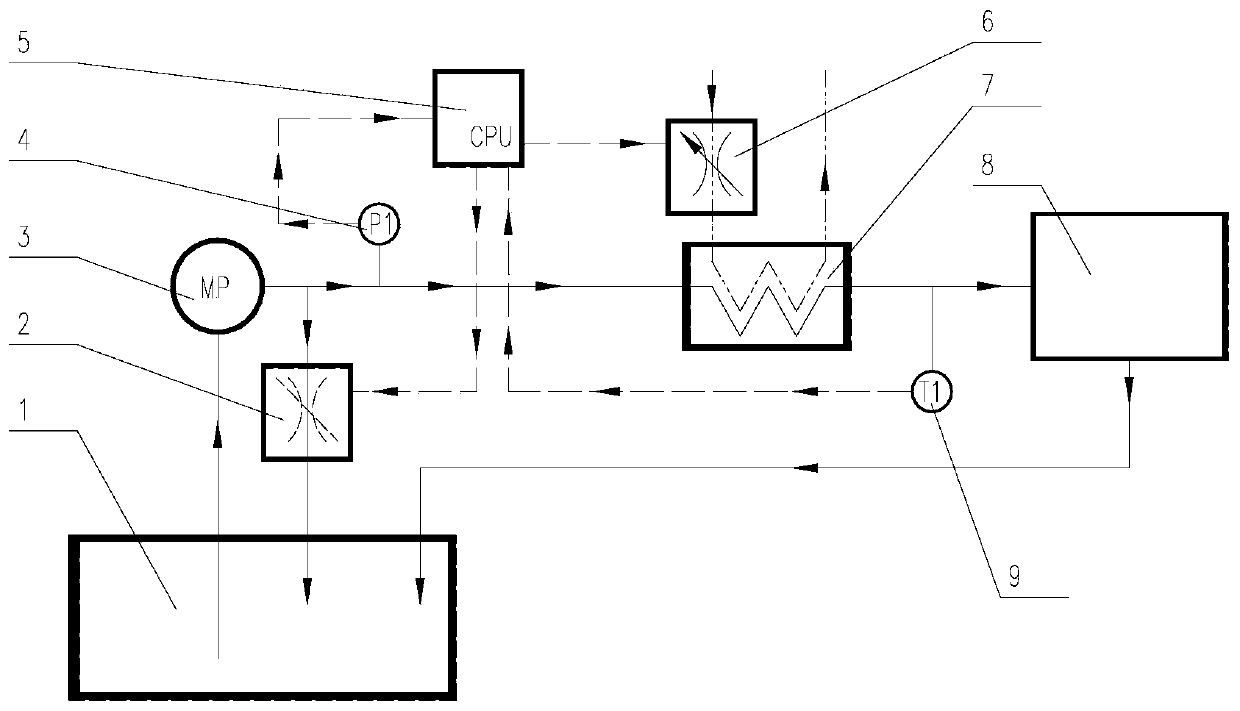

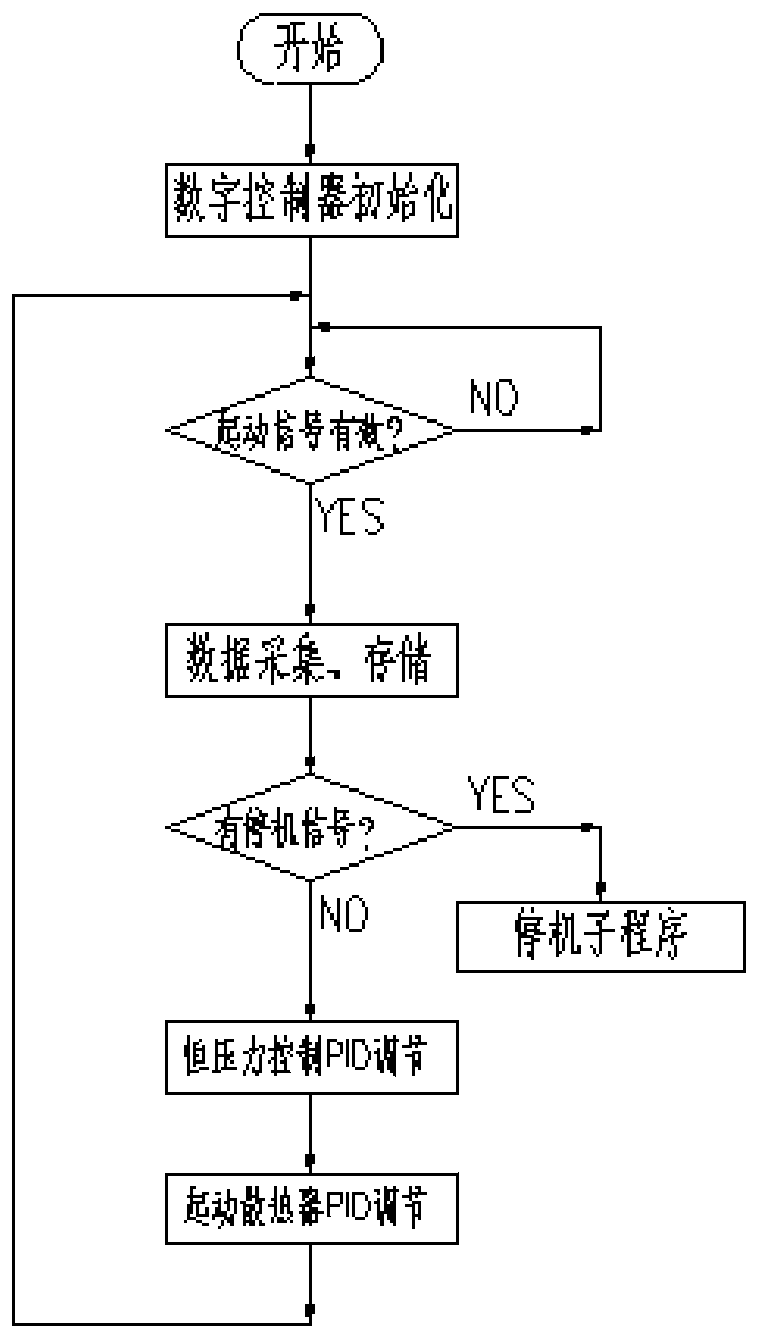

[0022] figure 1 It is a principle diagram of the present invention, wherein, the automatic pressure control system of the lubricating oil pumping station is composed of a lubricating oil tank 1, a lubricating oil pump 3, a lubricating mechanism 8, a regulating valve 2, connecting pipelines, a pressure transmitter 4, a digital controller 5, an electrical signal lines etc. In the figure, the thin solid lines with arrows indicate the connecting pipes and the flow direction of lubricating oil, and the dotted lines with arrows indicate the electrical signal lines and signal transmission directions. The lubricating oil flow path is: after the lubricating oil pump is started, the lubricating oil enters the lubricating oil pump 3 from the lubricating oil tank 1, and a part of the lubricating oil directly flows back to the lubricating oil tank from the lubricating oil pump outlet through the regulating valve 2 1. Part of the lubricating oil flows back to the lubricating oil tank 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com