Screw extrusion dehydrator

A technology of screw extrusion and dewatering machine, which is applied in the direction of presses, drying solid materials, manufacturing tools, etc., can solve problems such as inability to discharge water, and achieve the effect of improving extrusion efficiency, high extrusion efficiency and good drainage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

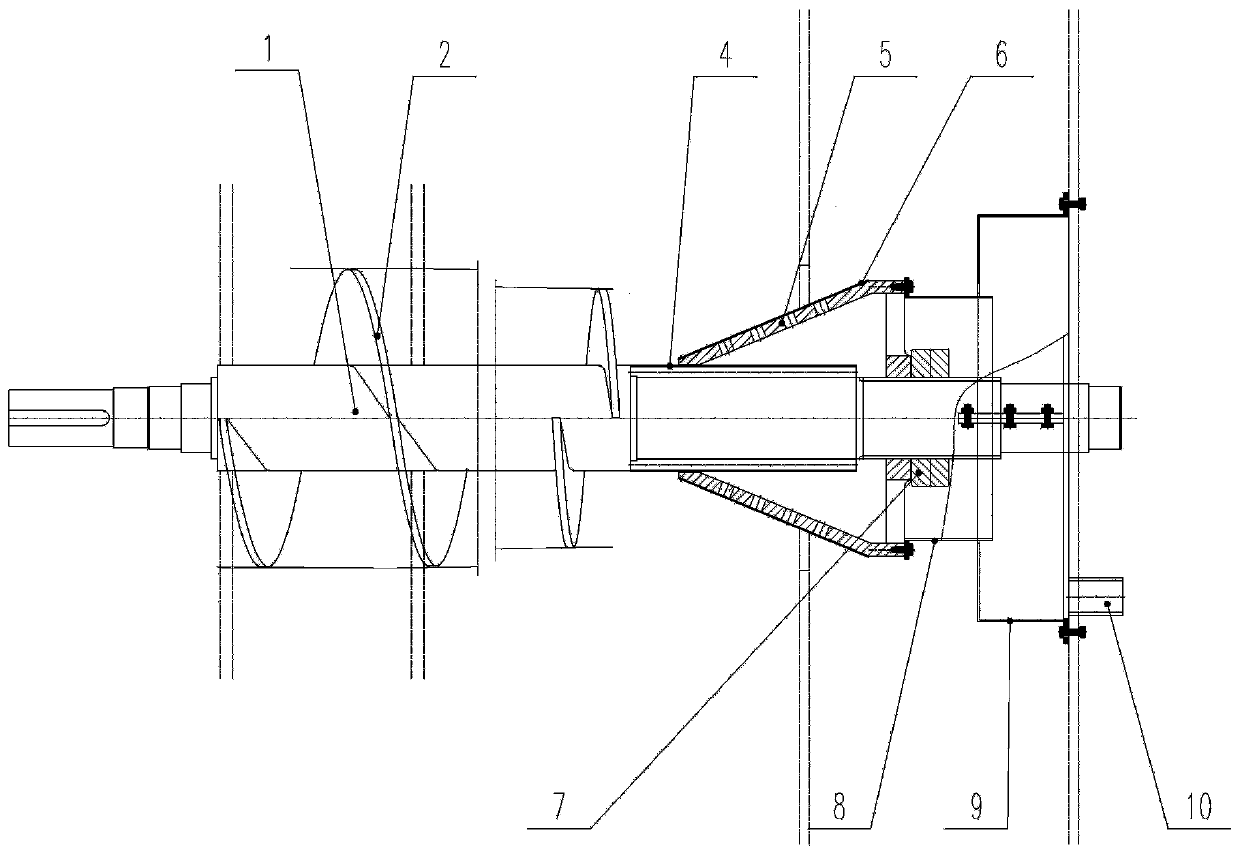

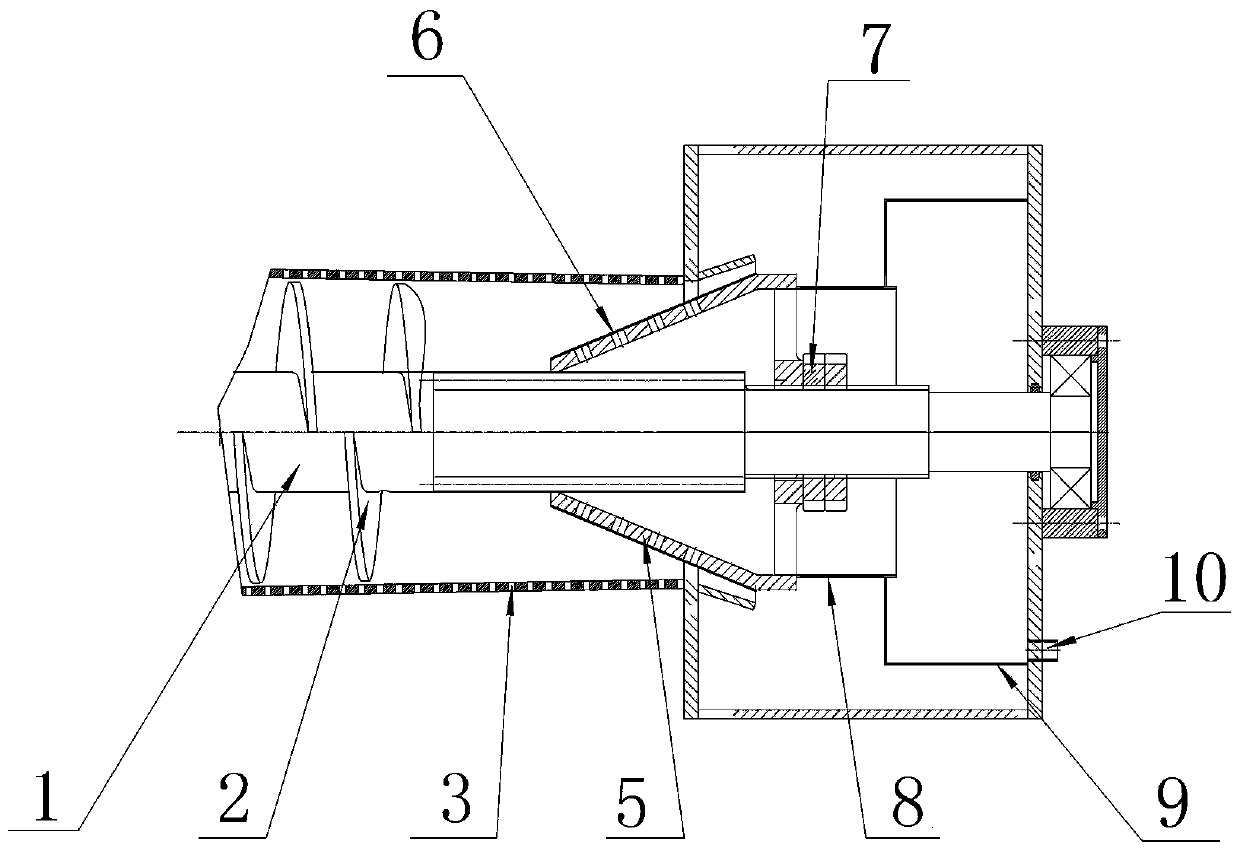

[0021] Such as Figure 1-2 Shown is a screw extrusion dehydrator of the present invention, which includes a shell, a screen drum 3 located inside the shell, and a rotating shaft 1. The screen drum is in the shape of a cone with a large front and a small rear. (The left side in the figure) is equipped with a spiral piece 2. The outer diameter of the spiral piece matches the conical sieve plate and gradually shrinks from front to back. There is a gap of 2-3mm between the outer edge of the spiral piece and the screen cylinder. The rear section of the shaft is a hollow structure, and the outer surface of this section of the rotating shaft is provided with a plurality of drainage holes 4, which can drain the water outside the shaft to the hollow inside the shaft, and discharge it from the drainage holes at the rear end of the shaft;

[0022] It also includes an extrusion head 5 matched with the rear section of the rotating shaft. The extrusion head is hollow in the shape of a trunc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com