Numerical display proving ring coefficient calibration device

A calibration device and ring coefficient technology, which is applied in the field of digital display measuring force ring coefficient calibration device, can solve the problems of low accuracy of measuring force ring coefficient, potential safety hazards in weights, and large human influence factors, etc., and achieve high precision and structure Simple, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

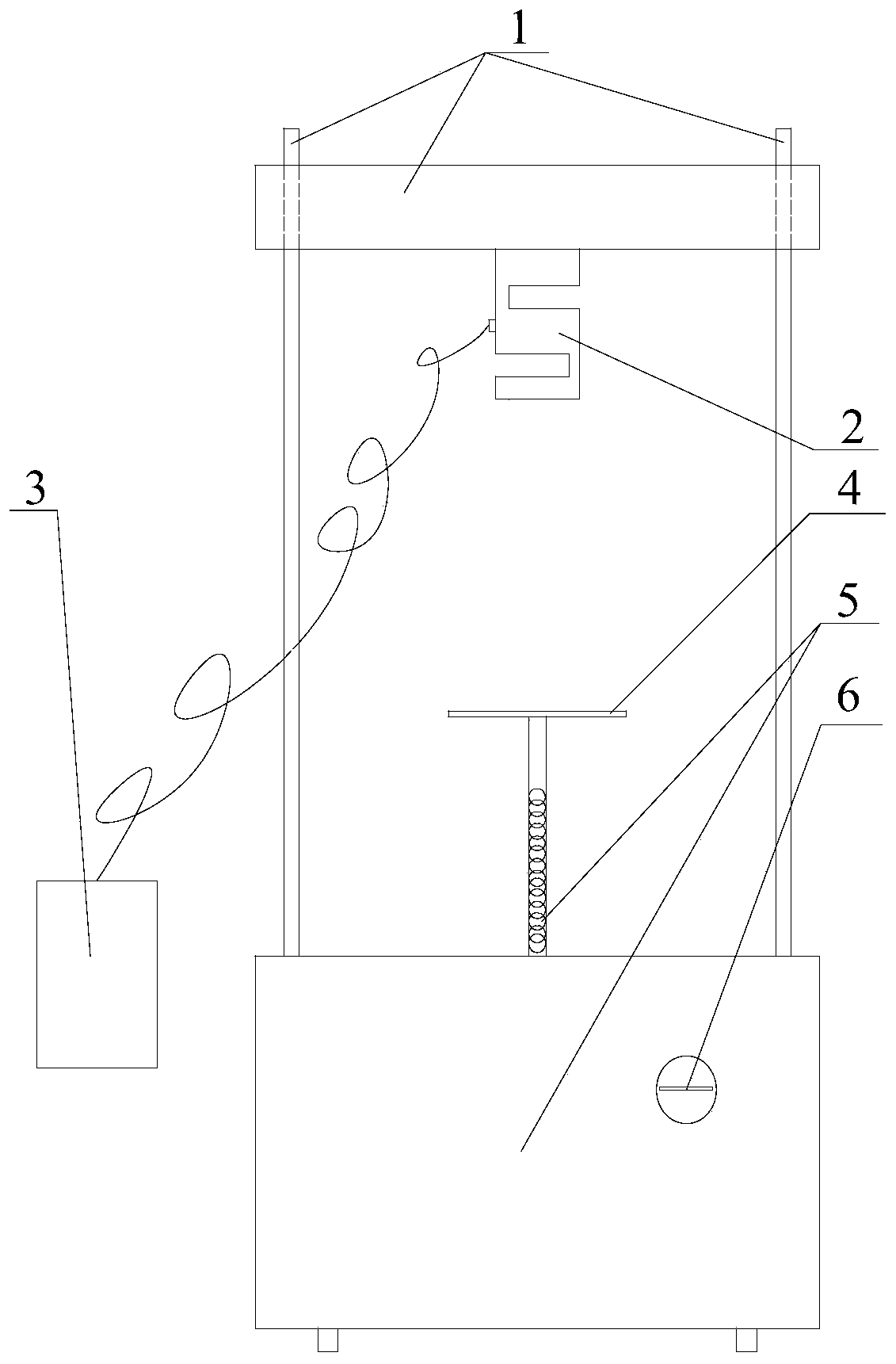

[0010] Such as figure 1 As shown, the digital display measuring force loop coefficient calibration device of the present invention includes: a reaction force frame, a force measuring device, a bearing platform, a lifting device, a power device, and the reaction force frame 1 includes two vertical supports and a crossbeam, between the support and the crossbeam The space is connected by screws and nuts, and the bracket is connected to the lifting device part 5 through threads; the force measuring device includes an S-type load cell 2 and a numerical display 3, and the S-type load cell 2 is connected to the beam through screws and nuts, and the numerical display 3 The data line is connected with the S-type load cell 2; the platform 4 is connected with the lifting device 5 through threads, and the power device 6 provides power for the lifting device 5, so as to achieve the purpose of adding load to the force ring.

[0011] The S-type load cell 2 has a measuring range of 2000N and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com