Seven-stranded steel strand embedded aluminum strain clamp crimped structure and crimping method thereof

A technology of tension-resistant clamps and steel strands, which is applied in the direction of connections, line/collector parts, and connections where permanent deformation plays a role, and can solve the problems of loose strands, reduced hardness of cold-drawn steel wires, and bitten steel strand wires And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

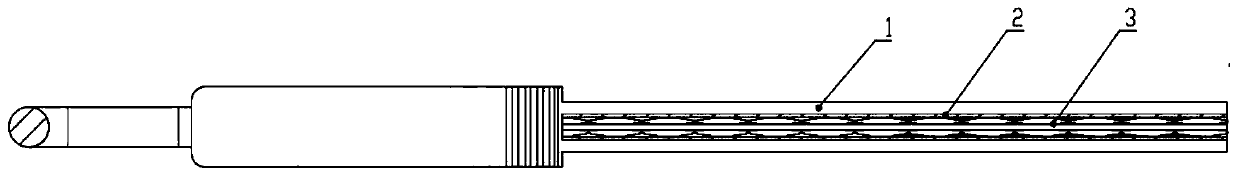

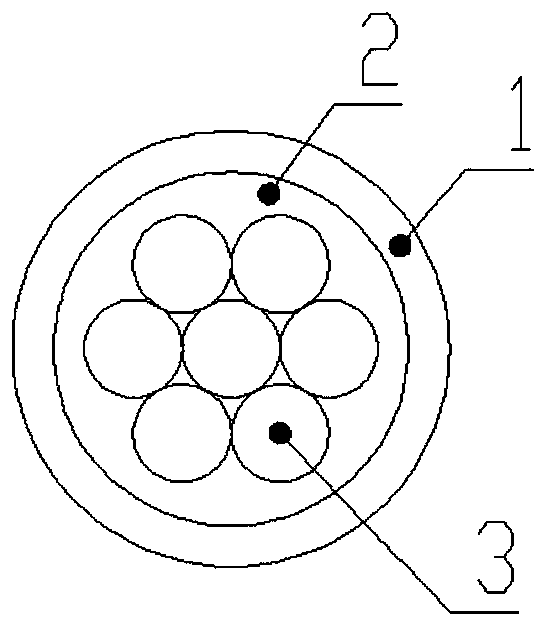

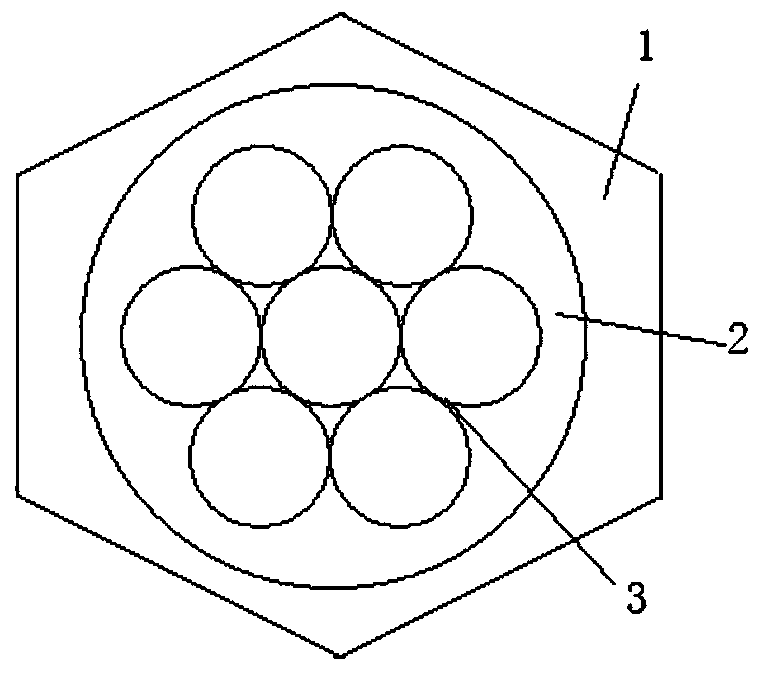

[0121] Embodiment 1: as Figure 1-Figure 3 As shown, a crimping structure of 7 twisted steel strands embedded with aluminum tension clamps, including a steel anchor crimping tube 1 and an aluminum embedded tube 2, the aluminum embedded tube 2 is embedded in the steel anchor crimping tube 1, and wrapped and penetrated Connect the round wire concentric stranded overhead conductors 7 stranded steel strands 3 at the end of the strain-resistant clamp, crimp the steel anchor crimping tube 1 so that the embedded aluminum tube 2 closely fits the round wire concentric stranded overhead conductors 7 stranded steel strands 3 to form a steel Stranded strain relief joints.

[0122] The aluminum-embedded tube 2 has a length of one steel core strand pitch.

[0123] A new type of round wire concentric stranded overhead conductor with 7 twisted steel strands embedded in aluminum tension clamp crimping tube, which is composed of outer layer steel anchor crimping tube and inner layer embedded a...

Embodiment 2

[0125] Embodiment 2: A crimping method for a crimping structure of 7 twisted steel strands embedded with aluminum tension clamps, the method comprising the following steps:

[0126] 1) Insert the embedded aluminum tube into the steel anchor crimping tube;

[0127] 2) Insert the steel strand from one end of the embedded aluminum tube, and insert the steel strand into the bottom of the clamp anchor ring;

[0128] 3) Use a crimping die to crimp the steel anchor crimping tube, so that the aluminum-embedded tube closely engages the surface of the steel strand and fills the gap between the steel anchor and the steel strand to form a steel strand tension joint.

[0129] Crimping stress after crimping the steel anchor crimping tube of the crimping die: when the press is not stopped after the steel anchor crimping tube is crimped, the inner radius of the steel anchor crimping tube is r fe , the center thickness of steel anchor crimping tube is d fe , the pitch diameter of steel core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com