A crimping method for 19 stranded steel-cored aluminum stranded wires embedded with aluminum tension clamps

A technology of steel-cored aluminum stranded wire and tension clamp, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of undervoltage, overvoltage, and reduced joint holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

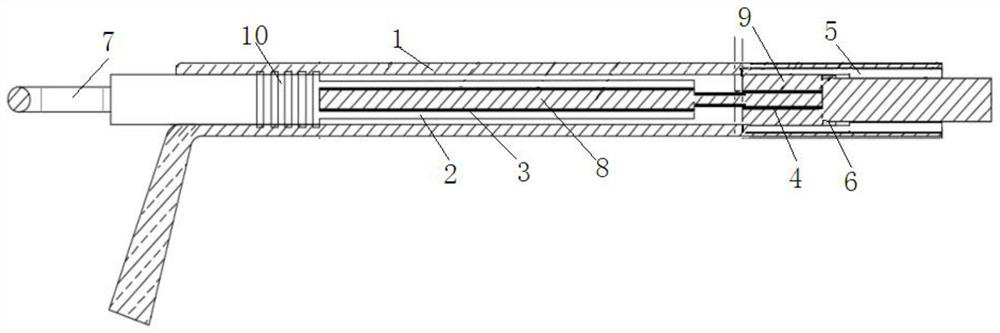

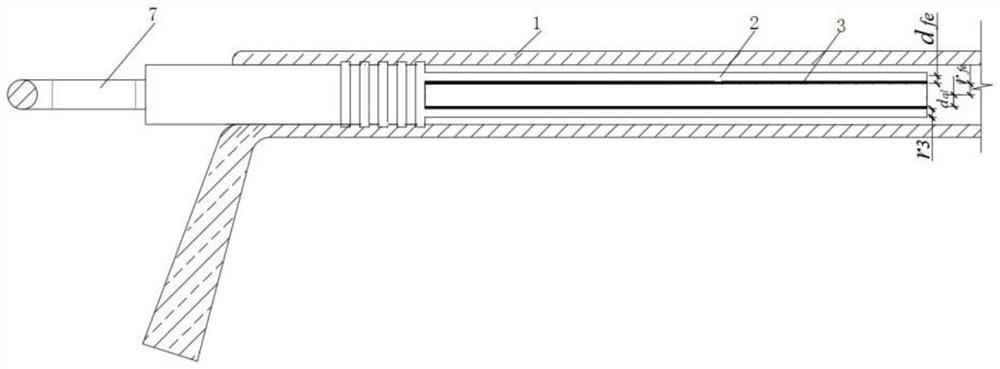

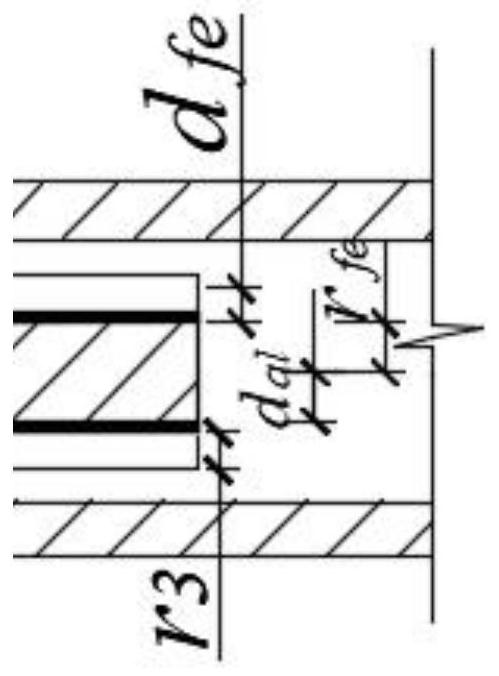

[0259] Embodiment 1: as Figure 1-5 As shown, a crimping method for 19 twisted steel-cored aluminum stranded wires embedded with aluminum tension clamps, including casing clamps 1, steel anchor crimping tubes 2, steel core embedded aluminum tubes 3, inner embedded layer aluminum tubes 4, outer Embedded aluminum tube 5, wire setting ring 6 and clamp anchor ring 7, steel core embedded aluminum tube 3 is sleeved on the steel strand 8 at the crimping end of the steel-cored aluminum stranded wire, and the steel anchor crimping tube 2 is sleeved on the steel core Outside the embedded aluminum tube 3, crimp the steel anchor crimping tube 2 so that the steel core embedded aluminum tube 3 closely fits the steel strand 3 to form a steel strand crimping joint; place the inner embedded layer aluminum tube 4 on the crimped steel core aluminum Between the steel strand 8 of the stranded wire and the inner aluminum strand layer 9, the steel core aluminum strand at the crimping end is connecte...

Embodiment 2

[0263] Embodiment 2: A full-tension aluminum-embedded crimping method for aluminum-steel-reinforced wires: the method includes the following steps:

[0264] 1) Strip the aluminum stranded wire at the crimped end of the steel cored aluminum stranded wire to expose the steel core, the length of the stripped section = the length of the steel anchor crimped tube + 20mm;

[0265] 2) Pull the crimped end of the steel-cored aluminum stranded wire stripped of the set length of the aluminum stranded wire until 10 meters, insert the aluminum sleeve clamp 1 from the end of the steel-cored aluminum stranded wire, and move the aluminum sleeve clamp 1 to the Does not affect the position of the next process;

[0266] 3) Insert the steel-cored aluminum stranded wire into the outer embedded aluminum tube 5, and press the large inner diameter end of the outer embedded aluminum tube 5 toward the joint, and move the outer embedded aluminum tube to a position that does not affect the next step of ...

specific example

[0507] Table 1. Parameters of ACSR

[0508]

[0509] Table 2. Calculation of parameters of steel core embedded aluminum tube

[0510]

[0511]

[0512] Table 3. Calculation of steel anchor crimping pipe crimping pipe parameters

[0513]

[0514] Table 4. Calculation of die parameters for steel anchor crimping pipe

[0515]

[0516] Table 5. Calculation of parameters of inner and outer embedded aluminum tubes

[0517]

[0518]

[0519] Table 6. Calculation of parameters of aluminum sleeve clamp

[0520]

[0521] Table 7. Calculation of die parameters

[0522]

[0523] Table 8. Calculation of crimping length parameters under the consideration of contact resistance and breaking force

[0524]

[0525]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com