Cooking appliance with water box component

A water box and component technology, applied in the direction of steam cooking utensils, cooking utensils, kitchen utensils, etc., can solve the problems that the size of the sealing part at the joint is difficult to completely match, the utilization rate of a box of water is reduced, and water seepage is easy to occur. To achieve a better effect of connection and coordination, connection coincidence, and avoid the effect of connection mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

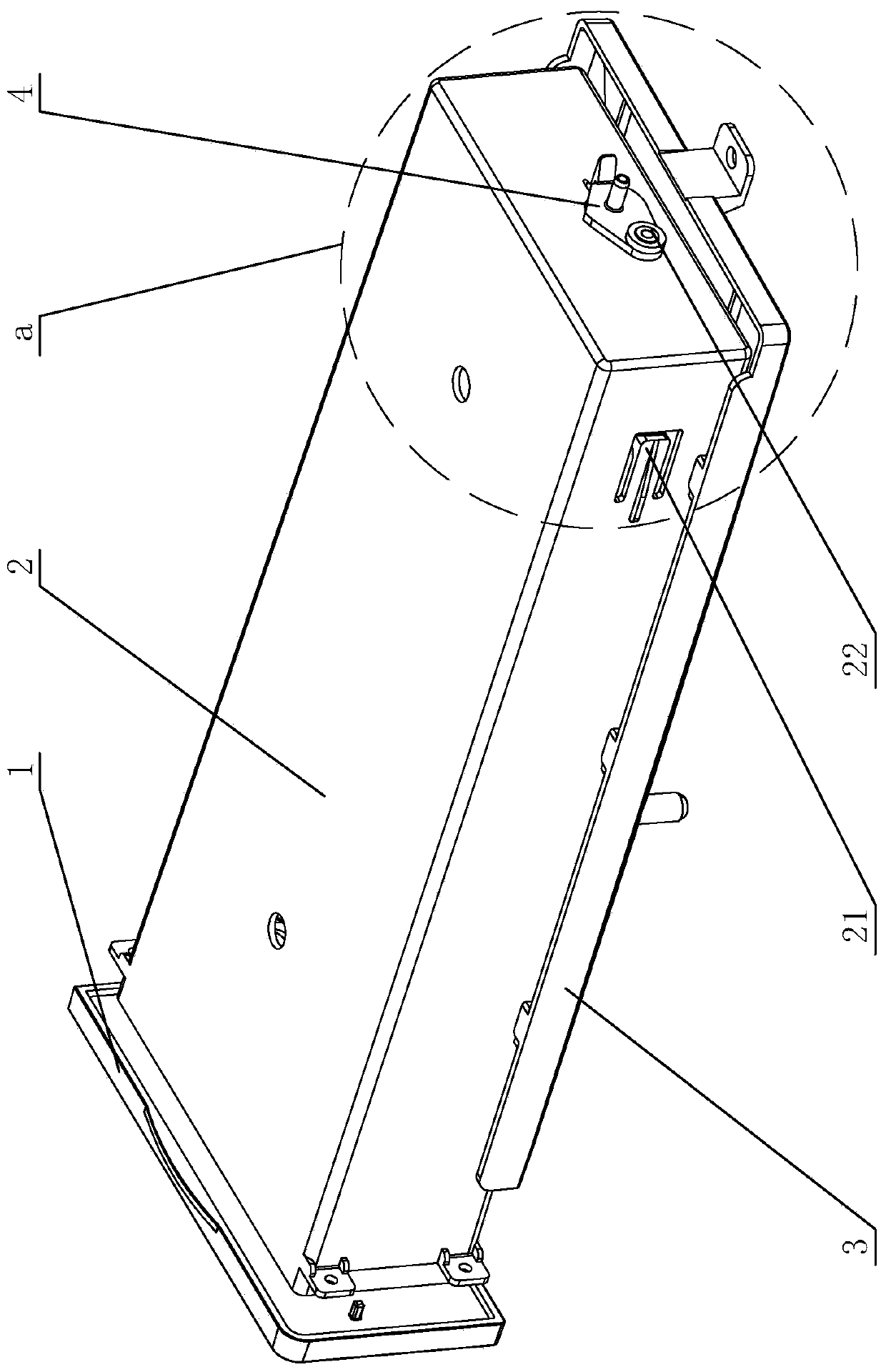

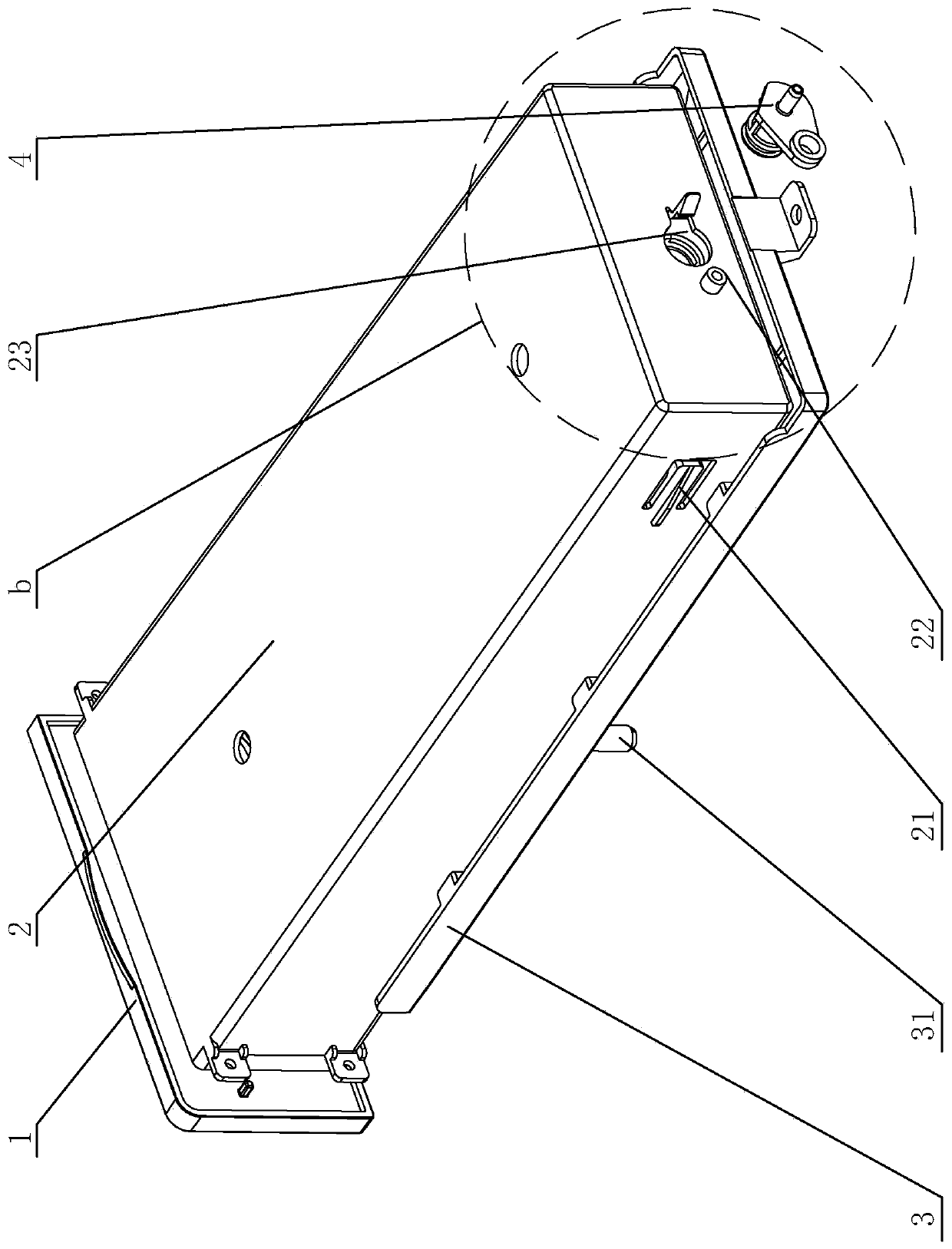

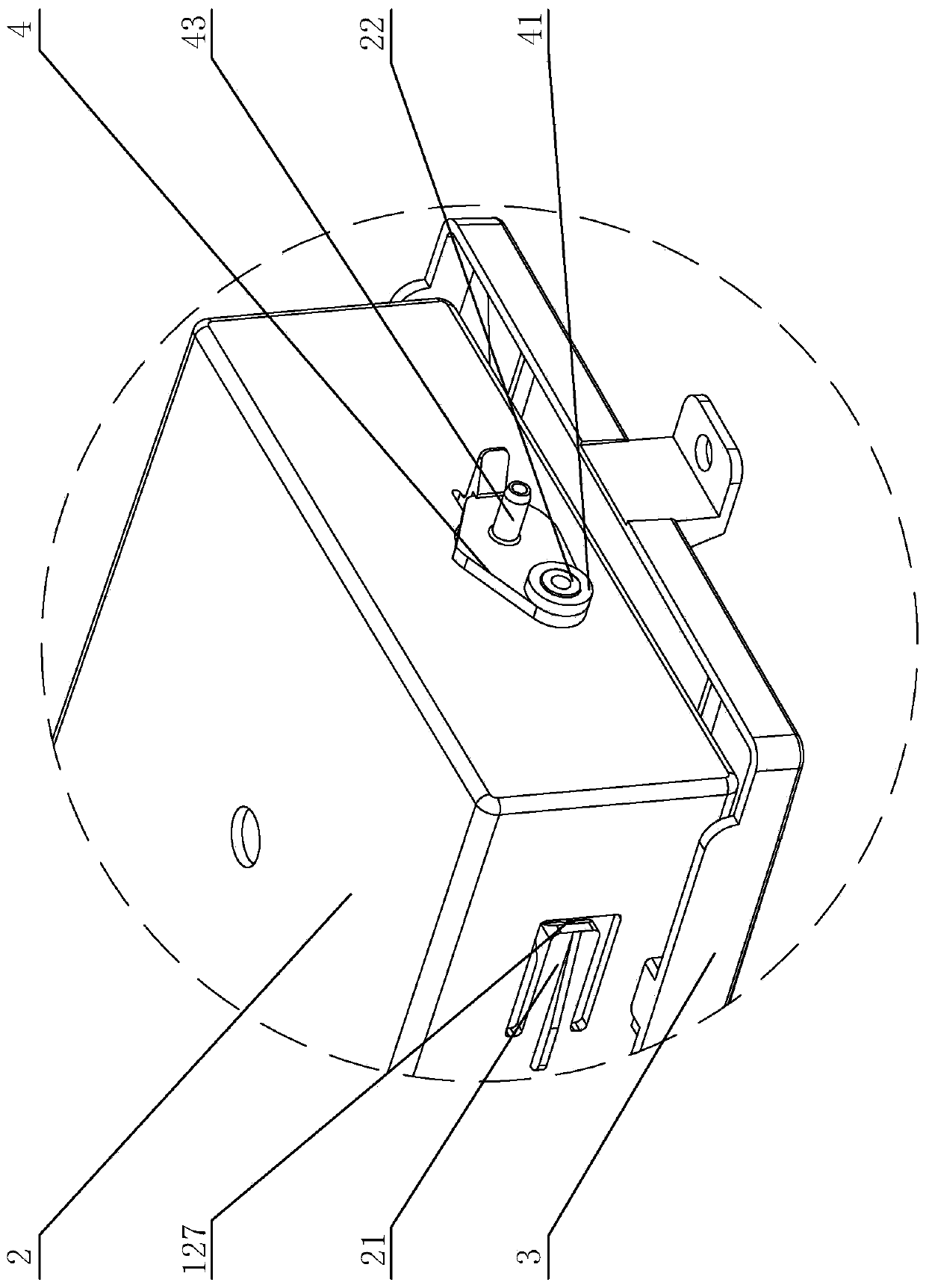

[0035] see Figure 1-Figure 16 , the cooking appliance with a water box assembly, the cooking appliance includes a box body 7, a door body 6, a control box 5 and a water collection box 9, the control box 5 is arranged on the top side of the door body 6, and the water box assembly includes a water box 1, The box cover 2 and the connector 4, the side wall of the box cover 2 is provided with a via hole 23, the connector 4 is connected with the via hole 23, the side wall of the box cover 2 is provided with a rotating shaft 22 adjacent to the position of the via hole 23, and the connector 4 is provided with a shaft sleeve 41, the shaft sleeve 41 is sleeved on the rotating shaft 22, so that the connecting piece 4 can rotate around the rotating shaft 22, the shaft sleeve 41 is connected with a rocker arm 42, one side of the rocker arm 42 is provided with a mal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com