Turnover type toilet ring high-pressure forming and blank taking integrated machine

A high-pressure molding and toilet seat technology, which is applied in ceramic extrusion dies, supply devices, unloading devices, etc., can solve the problems of large footprint, instability, and non-compactness, and optimize the overall equipment structure and reduce equipment. The effect of maintenance rate, good sharing and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

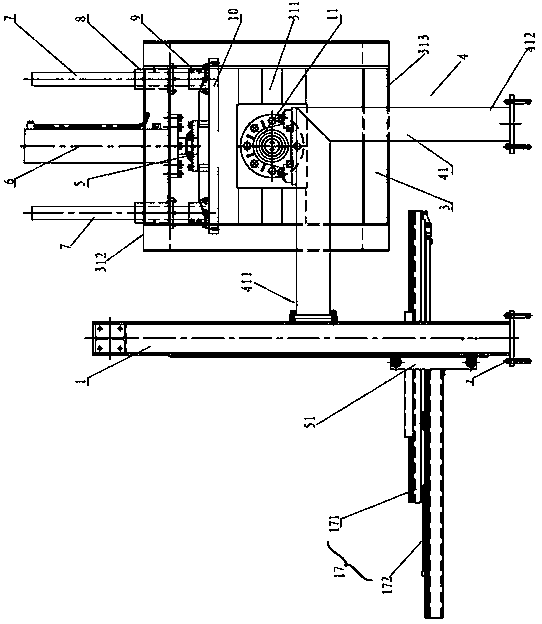

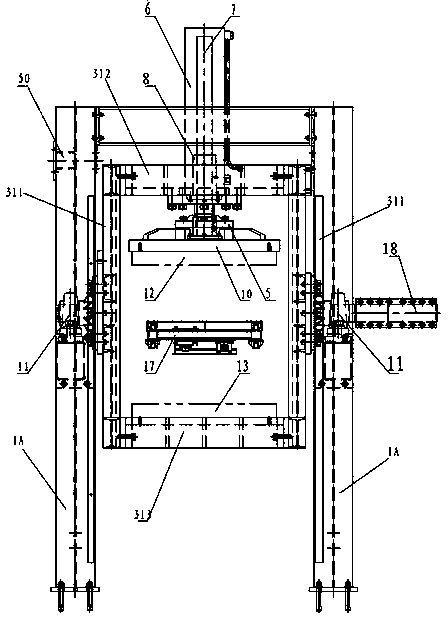

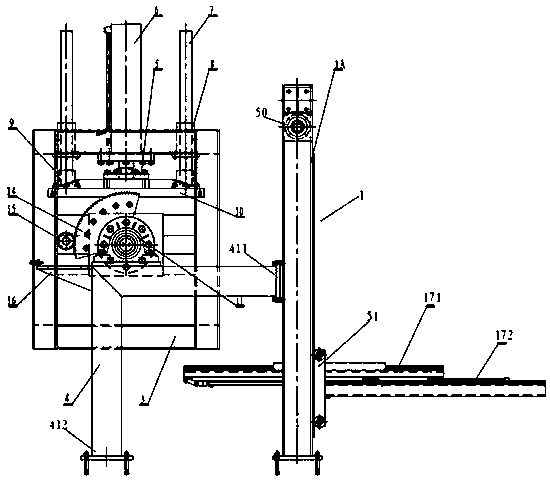

[0042] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0043] combine Figure 1-Figure 3 As shown, they are the right view, front view and left side view of the integrated machine for high-pressure molding and billet removal of the flip-type toilet ring of the present invention, respectively. 4. Bearing seat 11, flip frame 3, lifting cylinder 6, pressure plate 10, upper mold frame 12, lower mold frame 13, sector gear 14, transmission gear 15 and rotary drive motor (fixed on the motor support plate 16). The motor support plate 16 is fixed on the flip frame support frame 4 and is close to the position of the transmission gear 15 .

[0044] The frame 1 of the billet removal device includes at least two vertical supports 1A arranged oppositely, and the bottom of the vertical supports 1A is fixedly installed on the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com