Full-automatic cable erasing printing method

A printing method and fully automatic technology, applied in printing and post-processing of printing, etc., can solve problems affecting production efficiency, and achieve the effect of improving production efficiency, avoiding manual scrubbing, and ensuring printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

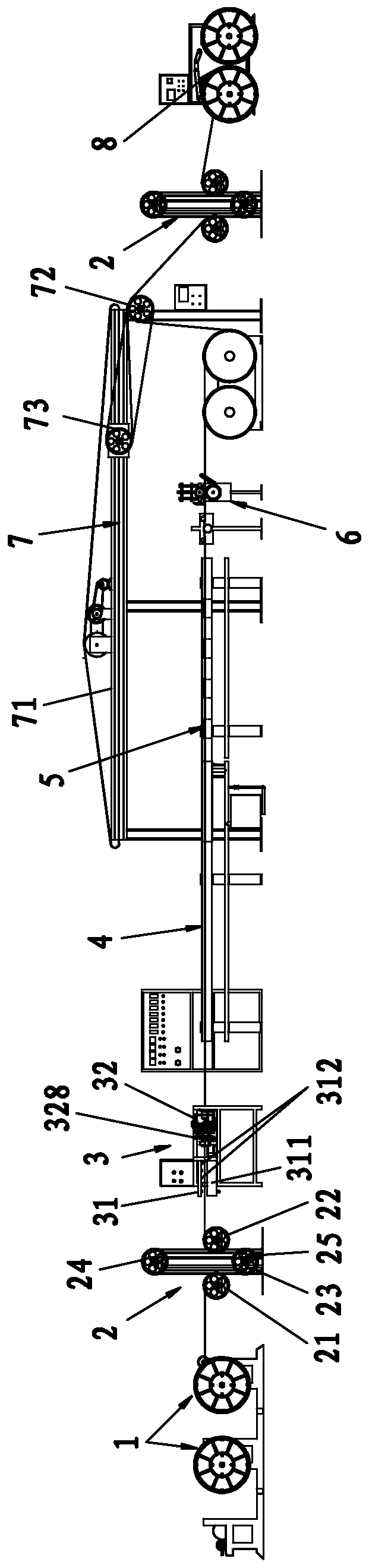

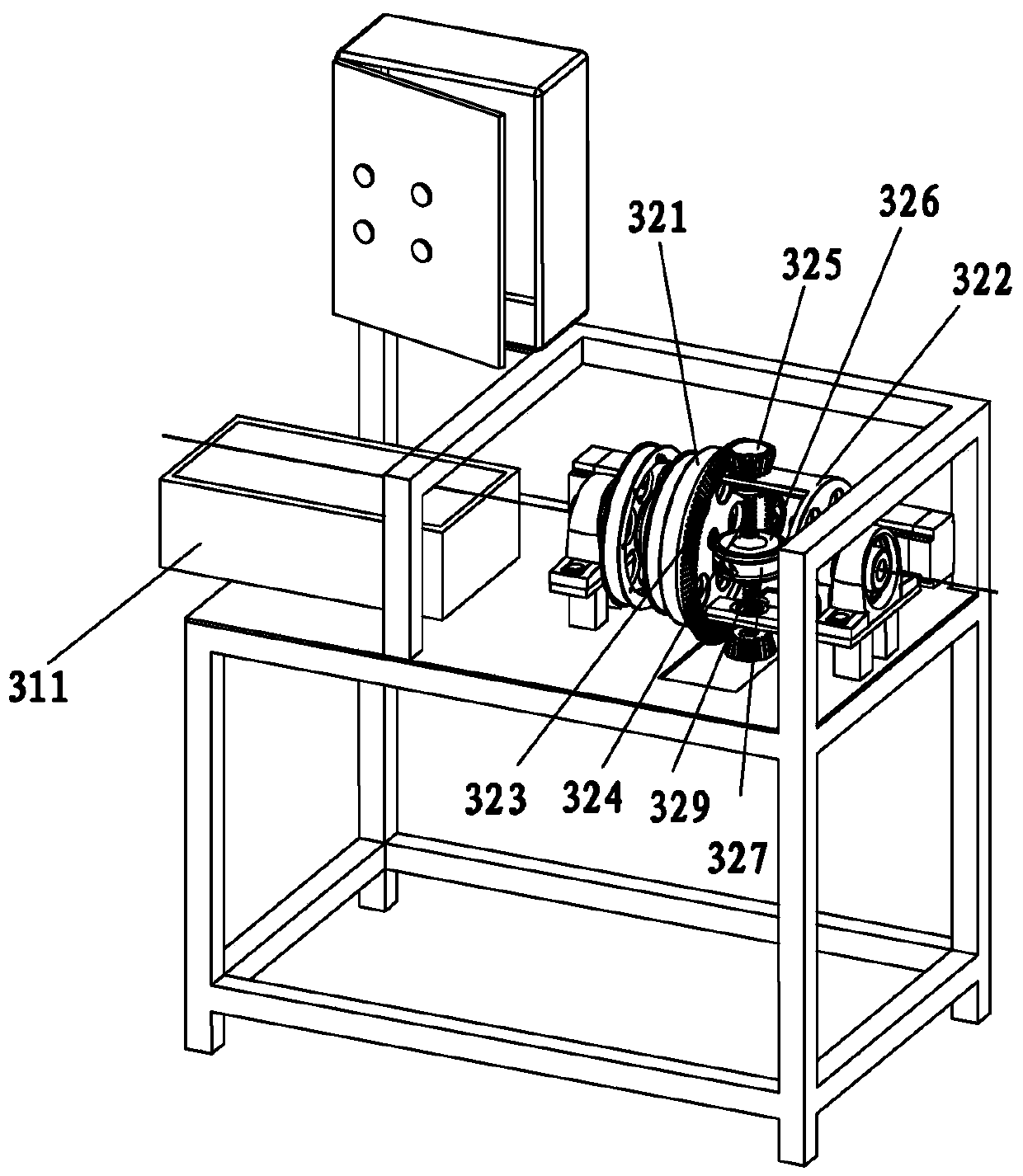

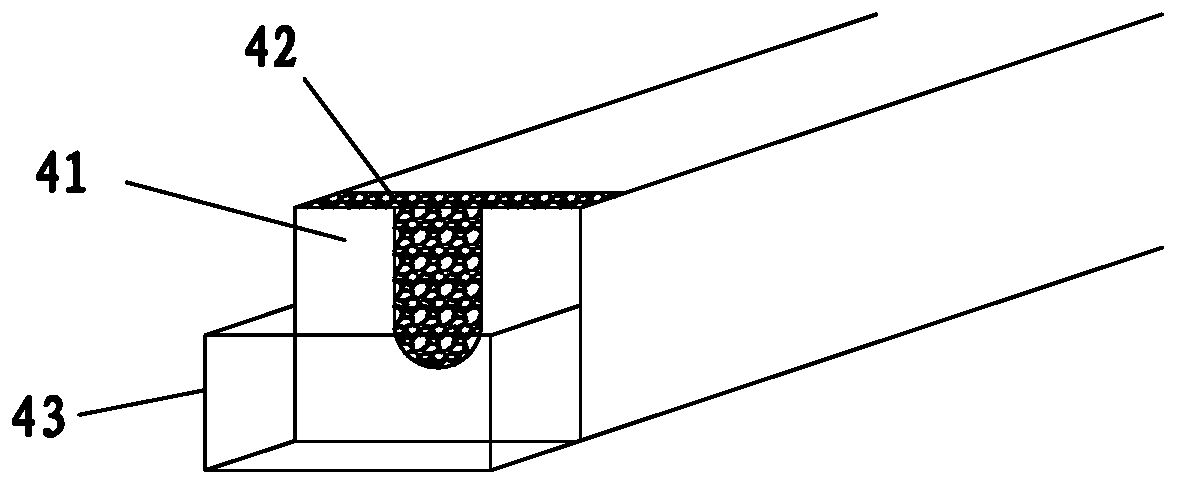

[0030] Please refer to the attached Figure 1-6 As shown, the preferred embodiments of the present invention are described in detail.

[0031] A fully automatic cable erasing and printing method, which mainly involves several steps and devices including an outlet frame 1, a buffer frame 2, an automatic polishing and erasing machine 3, a water tank 4, an air drying device 5, a synchronous printer 6, a storage Wire rack 7, wire take-up device 8. The cables with poor printing are all finished products in rolls, installed on the outlet frame 1 to release the wires, and the cables are buffered by the buffer 2 and then sent to the automatic grinding and erasing machine 3 to completely erase the writing. The automatic grinding and erasing machine After 3, a water tank 4 and an air-drying device 5 are provided. After erasing, the cables are washed in the water tank 4 filled with clean water, then air-dried, and sent to the synchronous printer 6 to print new characters. After printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com