A kind of silicon carbide-based porous ceramic with bionic structure and preparation method thereof

A technology of structural silicon carbide and porous ceramics, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of small pore diameter, low flexural strength, unfavorable long-term use of porous ceramics for high-efficiency filtration, etc., and achieves less energy consumption , low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

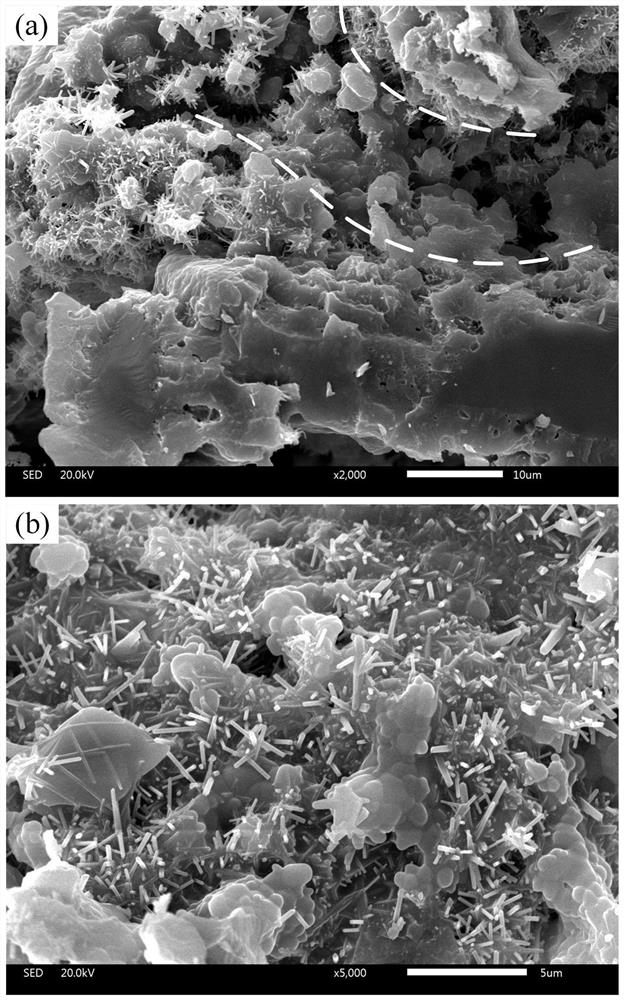

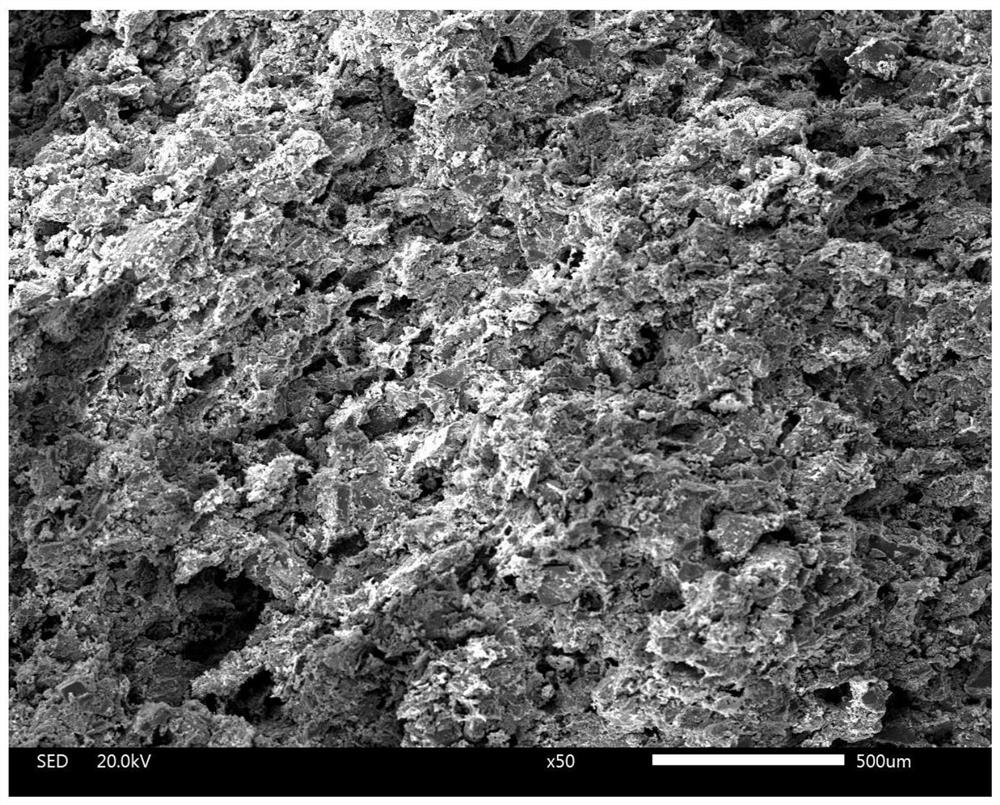

[0029] A silicon carbide-based porous ceramic with a biomimetic structure, the preparation method of which is as follows: ball-milling silicon carbide aggregates and sieving, and taking particles with a particle size of 88-150 μm for use; mixing a binder (made of kaolin and α-Al 2 o 3 Formed by mixing at a mass ratio of 62:38) after ball milling, pass through a 250 mesh sieve, and then mix 12.5wt% MoO into the sieved particles 3 , to get the binder, for subsequent use; get 76% ceramic aggregate, 24% binder in terms of the mass of the blank, and get 5% polyvinyl alcohol solution (mass fraction is 2%) in terms of the mass of the ceramic aggregate, and mix the ceramic aggregate , binder and polyvinyl alcohol solution were mixed and ball milled for 30 minutes to make them evenly mixed, and then a pore-forming agent (formed by mixing graphite with a particle size of 100 μm and activated carbon with a particle size of 100 μm in any mass ratio, and carbonized The quality of silicon ...

Embodiment 2

[0034] A silicon carbide-based porous ceramic with a biomimetic structure, the preparation method of which is as follows: ball-milling silicon carbide aggregates and sieving, and taking particles with a particle size of 88-150 μm for use; mixing a binder (made of kaolin and α-Al 2 o 3 Formed by mixing at a mass ratio of 70:30) after ball milling, pass through a 250 mesh sieve, and then mix 47wt% MoO into the sieved particles 3, to get the binding agent, standby; get 79% ceramic aggregate, 21% binding agent in blank mass, get 8% polyvinyl alcohol solution (mass fraction is 3.5%) in ceramic aggregate, ceramic aggregate, Binder and polyvinyl alcohol solution were mixed and ball milled for 40 minutes to make them evenly mixed, and then a pore-forming agent (formed by mixing graphite with a particle size of 150 μm and activated carbon with a particle size of 150 μm in any mass ratio, and silicon carbide Aggregate and binder mass and its addition amount are 25%) and ball milling an...

Embodiment 3

[0038] A silicon carbide-based porous ceramic with a biomimetic structure, the preparation method of which is as follows: ball-milling silicon carbide aggregates and sieving, and taking particles with a particle size of 88-150 μm for use; mixing a binder (made of kaolin and α-Al 2 o 3 Formed by mixing at a mass ratio of 78:22) after ball milling, pass through a 250 mesh sieve, and then mix 62.5wt% MoO into the sieved particles 3 , to get the binding agent, for subsequent use; get 82% ceramic aggregate, 18% binding agent in blank mass, get 10% polyvinyl alcohol solution (mass fraction is 5%) in ceramic aggregate, ceramic aggregate, Binder and polyvinyl alcohol solution were mixed and ball milled for 60 minutes to make them evenly mixed, and then a pore-forming agent (formed by mixing graphite with a particle size of 200 μm and activated carbon with a particle size of 200 μm in any mass ratio, and silicon carbide Aggregate and binder mass and its addition amount are 25%) and ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com