A roll-type membrane element and its preparation method and application

A roll-type membrane and component technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as failure to achieve, low efficiency, small filtration area, etc., to improve efficiency and improve filtration efficiency , the effect of large filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

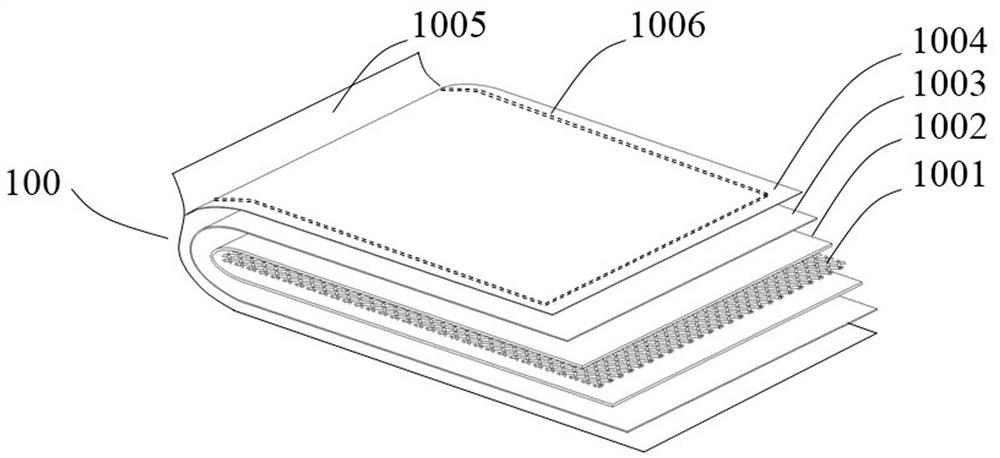

[0144] The method for preparing the combined membrane unit 100 in the embodiment of the present invention includes the following steps:

[0145] Taking the feeding partition 1001 as the center, stack the double-sided non-woven fabric 1002, the hydrophilic modified polymer microporous membrane 1003 and the flow guide cloth 1004 in sequence; then coat the surface of the flow guide cloth 1004 with two-component polyurethane glue to seal Form glue seal line 1006, that is.

[0146] The distance between the glue sealing line 1006 and the edge of the diversion cloth 1004 is 1 cm to 3 cm.

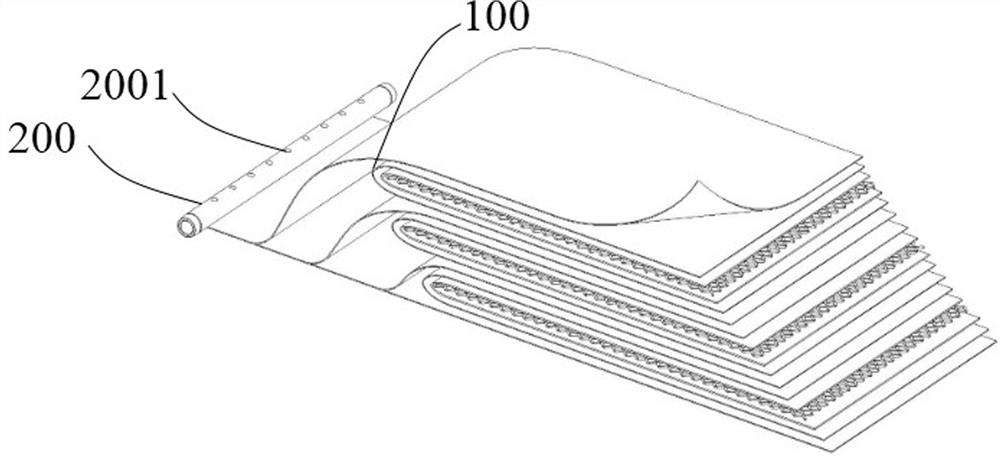

[0147] The preparation method of the rolled membrane element in the embodiment of the present invention, such as figure 2 shown, including the following steps:

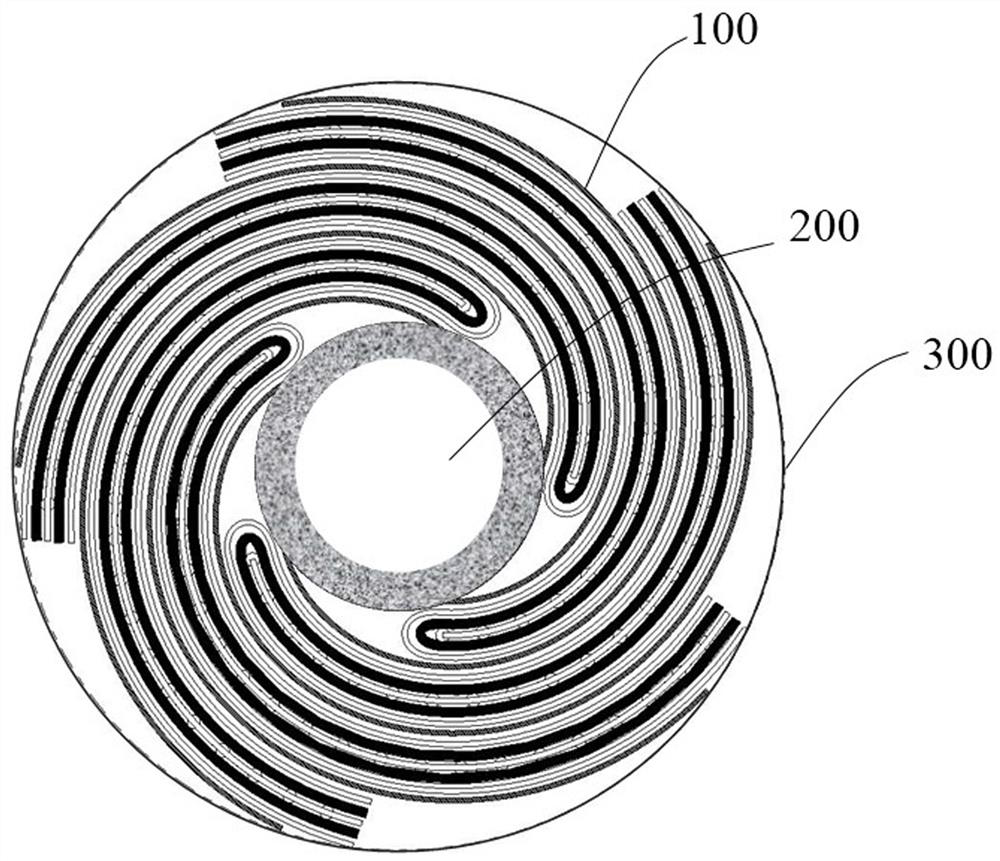

[0148] Several combined membrane units 100 are rolled around the central tube 200, that is, as image 3 or Figure 4 Spiral membrane element shown.

[0149] The central tube 200 is also provided with a number of central tube holes 20...

Embodiment 1

[0164] This embodiment is a method for preparing a rolled membrane element, comprising the following steps:

[0165] S1. Select double-sided non-woven fabric 1002 and use plasma for surface pretreatment. The treatment frequency is 13.6 MHz, room temperature, and irradiation time is 900s; the average pore diameter of the first porous surface of the treated non-woven fabric is 3.2 μm, and the second The average pore diameter of the porous surface is 0.58μm, the average thickness is 62μm, and the blanking size: the length is 1750mm, and the width is 1067mm;

[0166]S2. Select a polytetrafluoroethylene microporous membrane with an average pore size of 0.03 μm (Shenzhen Shengan Technology Co., Ltd., e-PTFE-204) for hydrophilic modification. The specific conditions are as follows: the monomer (N, N, N- Trimethyl-3-[(2-methyl-1-oxo-2-propenyl)amino]-1-propylammonium chloride (CAS No.: 68039-13-4) and diamine maleate (CAS No.: 928-01-8)) was dissolved in an aqueous solution of aceton...

Embodiment 2

[0180] This embodiment is a method for preparing a rolled membrane element, comprising the following steps:

[0181] S1. Select double-sided non-woven fabric 1002 and use plasma for surface pretreatment. The treatment frequency is 13.6 MHz, room temperature, and irradiation time is 900s; the average pore diameter of the first porous surface of the treated non-woven fabric is 3.2 μm, and the second The average pore diameter of the porous surface is 0.58 μm, the average thickness is 62 μm, the length of the blank is 1750 mm, and the width is 1067 mm.

[0182] S2. Use a polypropylene microporous membrane with an average pore size of 0.021 μm (Shenzhen Xingyuan Material Technology Co., Ltd., SD220202) for hydrophilic modification. The specific conditions are as follows: monomer (sodium methacrylate (CAS No. : 1561-92-8) with N,N,N-trimethyl-3-[(2-methyl-1-oxo-2-propenyl)amino]-1-propylammonium chloride) at room temperature Dissolved in 70% acetone aqueous solution to obtain a mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com