A blood filter material for removing white blood cells and its preparation method

A technology of blood filtration and white blood cells, which is applied in separation methods, filtration separation, membrane filters, etc., can solve the problems of increased blood filtration time, poor safety of electrospinning technology, and influence on operating efficiency, so as to shorten blood filtration time and improve Blood wettability, effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A blood filter material for removing leukocytes, the blood filter material includes a primary filter layer and a fine filter layer, the primary filter layer is a centrifugal spinning layer, the fine filter layer is a melt-blown layer, the primary filter layer is attached to the surface of the fine filter layer, Moreover, both the primary filter layer and the fine filter layer are polybutylene terephthalate / silk fibroin composite fibers.

[0031] The thickness of the fine filter layer is 0.05 mm, the diameter of the composite fiber used for the fine filter layer is 300 nm, and the pore size is 0.5 μm.

[0032] The thickness of the primary filter layer is 0.5mm, the diameter of the composite fiber used for the primary filter layer is 1 μm, and the pore size is 2 μm.

[0033] A preparation method for removing leukocyte blood filter material, said preparation method comprising the following steps:

[0034] a. Preparation of fine filter layer

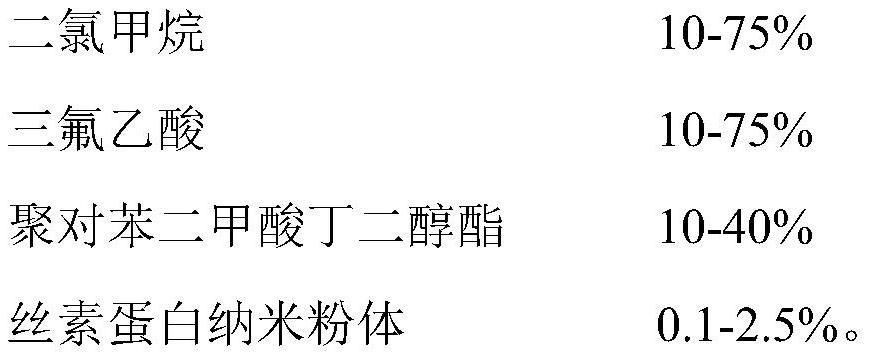

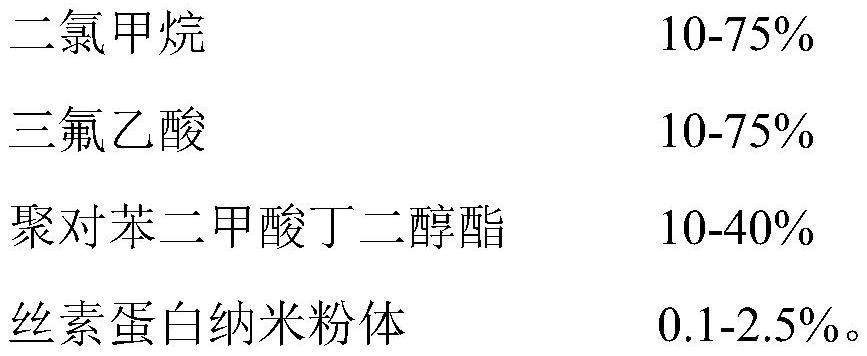

[0035] After blending polybu...

Embodiment 2

[0043] A blood filter material for removing leukocytes, the blood filter material includes a primary filter layer and a fine filter layer, the primary filter layer is a centrifugal spinning layer, the fine filter layer is a melt-blown layer, the primary filter layer is attached to the surface of the fine filter layer, Moreover, both the primary filter layer and the fine filter layer are polybutylene terephthalate / silk fibroin composite fibers.

[0044] The thickness of the fine filter layer is 0.1 mm, the diameter of the composite fiber used for the fine filter layer is 1000 nm, and the pore size is 2 μm.

[0045] The thickness of the primary filter layer is 1 mm, the diameter of the composite fiber used for the primary filter layer is 3 μm, and the pore size is 5 μm.

[0046] A preparation method for removing leukocyte blood filter material, said preparation method comprising the following steps:

[0047] a. Preparation of fine filter layer

[0048] After blending polybutyl...

Embodiment 3

[0056] A blood filter material for removing leukocytes, the blood filter material includes a primary filter layer and a fine filter layer, the primary filter layer is a centrifugal spinning layer, the fine filter layer is a melt-blown layer, the primary filter layer is attached to the surface of the fine filter layer, Moreover, both the primary filter layer and the fine filter layer are polybutylene terephthalate / silk fibroin composite fibers.

[0057] The thickness of the fine filter layer is 0.2 mm, the diameter of the composite fiber used for the fine filter layer is 2000 nm, and the pore size is 3 μm.

[0058] The thickness of the primary filter layer is 1.5 mm, the diameter of the composite fiber used for the primary filter layer is 5 μm, and the pore size is 10 μm.

[0059] A preparation method for removing leukocyte blood filter material, said preparation method comprising the following steps:

[0060] a. Preparation of fine filter layer

[0061] After blending polybu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com