Dihydrate azithromycin sphaerocrystal and preparation method thereof

A technology of azithromycin and spherical crystals, which is applied in the field of spherical crystals of azithromycin dihydrate and its preparation, and achieves the effects of low equipment requirements, good fluidity and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

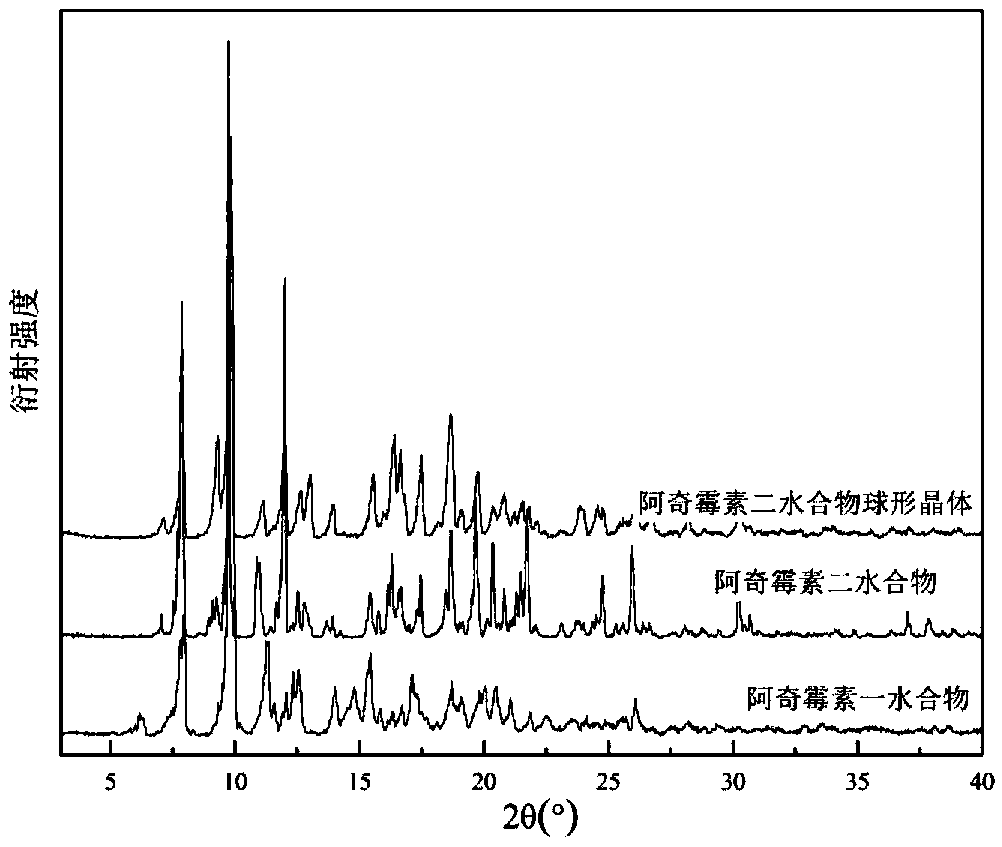

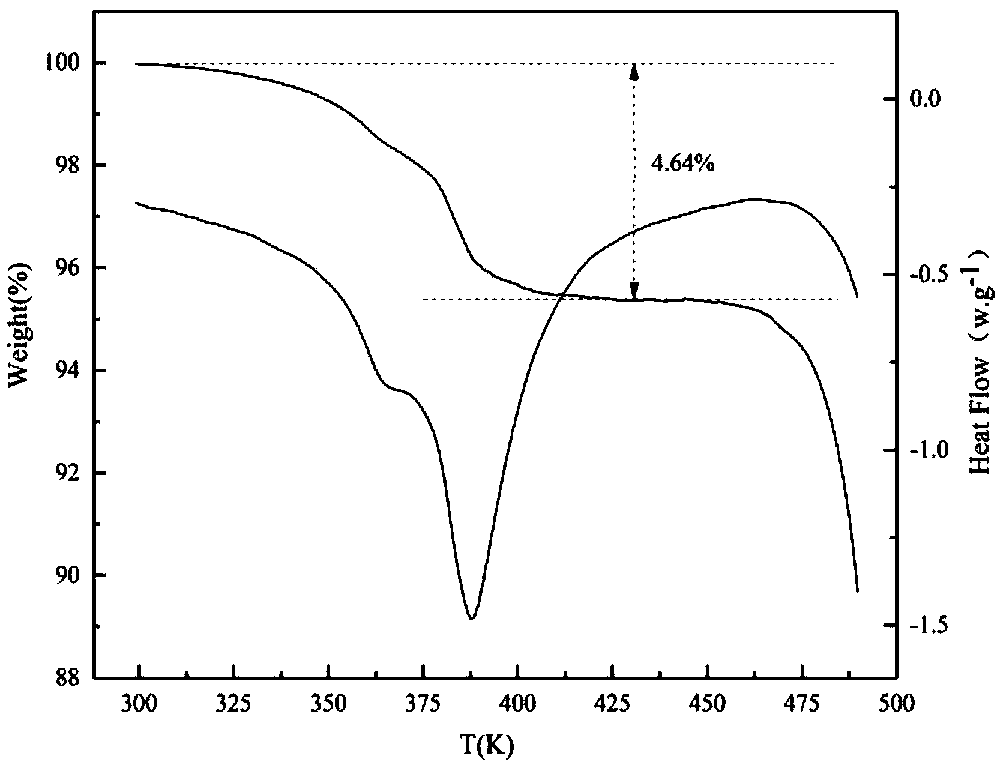

[0030] Add 80g of azithromycin solid to a mixed solvent of 75g of acetone and 25g of ethyl acetate, then raise the temperature to 40°C, set the stirring rate to 1000rpm, and add 200g of deionized water dropwise at 10g / min after the azithromycin is completely dissolved, and then Crystals began to precipitate slowly and gradually formed spherical particles. After the dropwise addition, the crystals were grown at a constant temperature and stirred for 30 minutes, and finally the crystal slurry was filtered with suction. After the filter cake was dried in vacuum at 50°C to constant weight, spherical azithromycin dihydrate was obtained product. The product purity that this method obtains is 99.3%, and the one-way molar yield of crystallization process is 91.5%, and the X-ray powder diffraction pattern of product is as follows figure 2 As shown, the thermal analysis diagram of the product is shown in image 3 , the product looks like Figure 4 As shown, the main particle size is ...

Embodiment 2

[0032] Add 50 g of azithromycin solid into a mixed solvent of 60 g of ethanol and 40 g of isopropyl acetate, set the stirring rate at 800 rpm, keep the temperature at 30° C., and add 250 g of deionized water dropwise at 10 g / min after the azithromycin is completely dissolved. During the process of adding water dropwise, the solution changes from clarification to turbidity and crystals are gradually precipitated out, finally forming spherical particles. After the dropwise addition, grow the crystals at a constant temperature and stirring for 60 minutes, then suction filter the crystal slurry formed, and filter the filter cake at 50 After drying at ℃ to constant weight, the product of spherical azithromycin dihydrate is obtained. The purity of the product obtained by the method is 99.2%, and the single-pass molar yield in the crystallization process is 91.1%, and the appearance of the product is as follows: Figure 5 As shown, the main particle size is 1mm, the particle size dis...

Embodiment 3

[0034]Add 50 g of azithromycin solid into a mixed solvent of 50 g of acetone and 50 g of ethyl acetate, raise the temperature to 30° C., set the stirring rate at 500 rpm, and add 300 g of deionized water dropwise at 10 g / min after the azithromycin is completely dissolved. The crystals began to precipitate slowly, and gradually formed spherical crystals. After the dropwise addition, the crystals were grown at a constant temperature and stirred for 90 minutes, and then the crystal slurry was filtered with suction. After the filter cake was dried at 55°C to constant weight, the spherical azithromycin dihydrate product was obtained. . The product purity that this method obtains is 99.2%, and the one-way molar yield of crystallization process is 90.5%, and product outward appearance is as Figure 6 As shown, the main particle size is 2mm, the particle size distribution is uniform, the angle of repose is 20°, and the product has good fluidity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com