Road piezoelectric power generation deceleration strip

A piezoelectric power generation and speed bump technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of low energy utilization rate, single piezoelectric energy conversion mode of speed bump, complex mechanical structure, etc. Simple structure and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

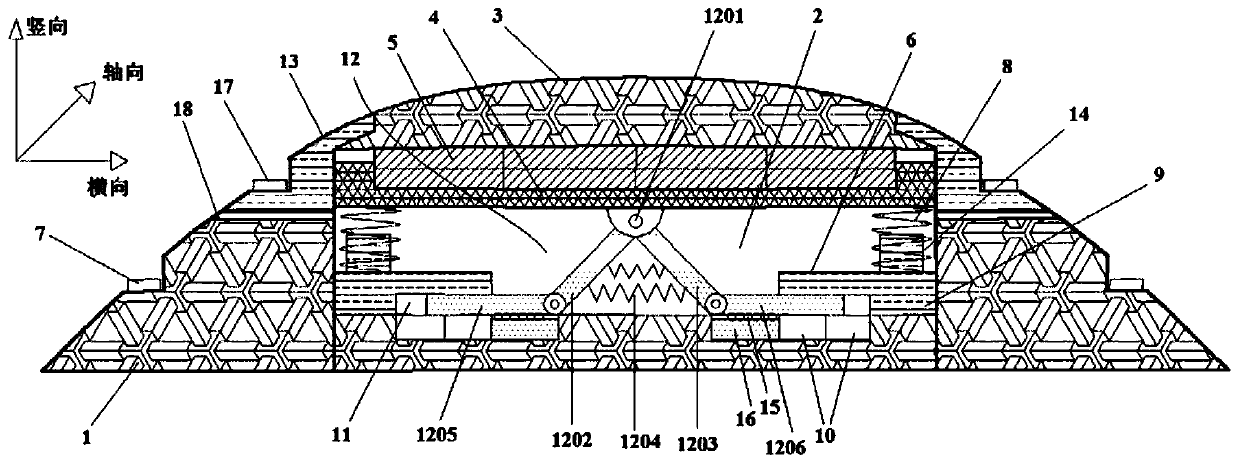

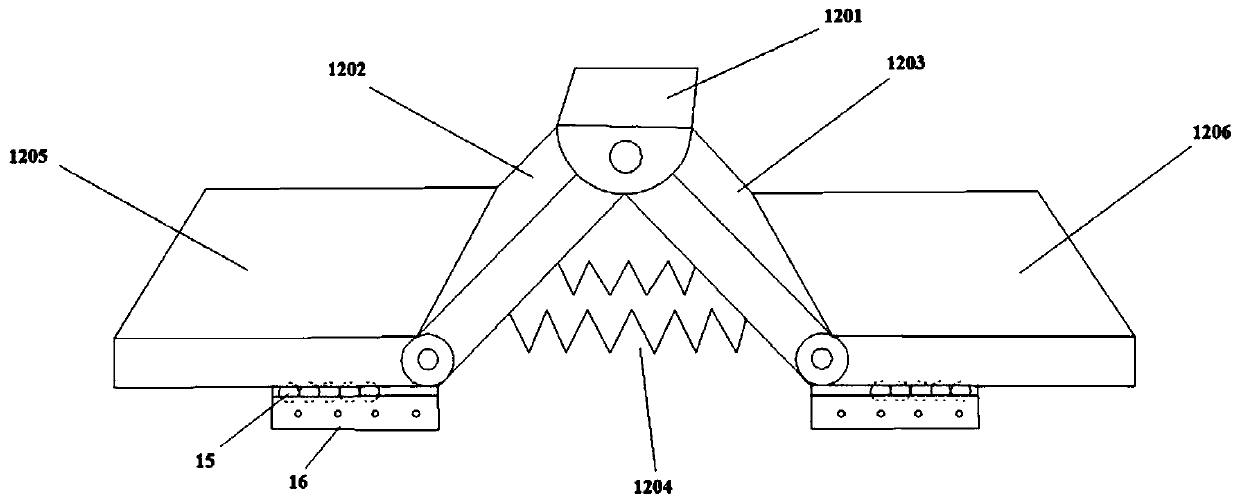

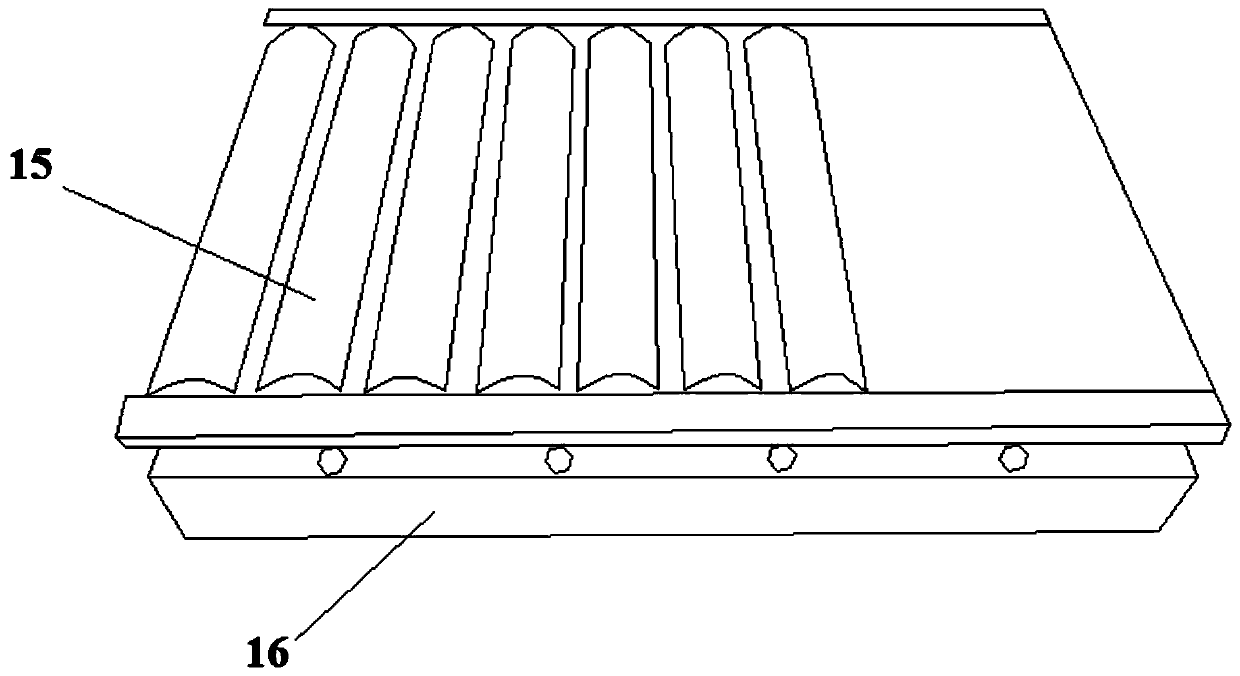

[0043] Following the above technical solution, this embodiment provides a road-use piezoelectric power generation deceleration belt, such as Figure 1 to Figure 6 As shown, including the base 1, the base 1 is provided with a cavity 2 with an open top, and the open top of the cavity 2 is provided with a pressure-bearing cover 3, and the pressure-bearing cover 3 can move vertically relative to the base 1;

[0044] A sinking-floating tray 4 is arranged in the cavity 2 below the pressure-bearing cover 3, and more than one layer of d is arranged between the sinking-floating tray 4 and the pressure-bearing cover 3 33 Piezoelectric energy harvesting sheet 5; the pressure-bearing cover 3 is pressed down vertically so that d 33 The piezoelectric energy harvesting sheet 5 is squeezed to generate electricity;

[0045] A cantilever support plate 6 is arranged on the vertical inner wall of the cavity 2 along the axial direction, and the bottom ends of a plurality of vertical return spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com