Two-layer waste gas treatment system based on emission concentration monitoring

A technology for waste gas treatment and emission concentration, which is applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of increasing waste water production by absorbing liquid, increasing enterprise operating costs, and increasing waste water treatment costs, etc., to increase the treatment process , reduce the amount of use, improve the effect of absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

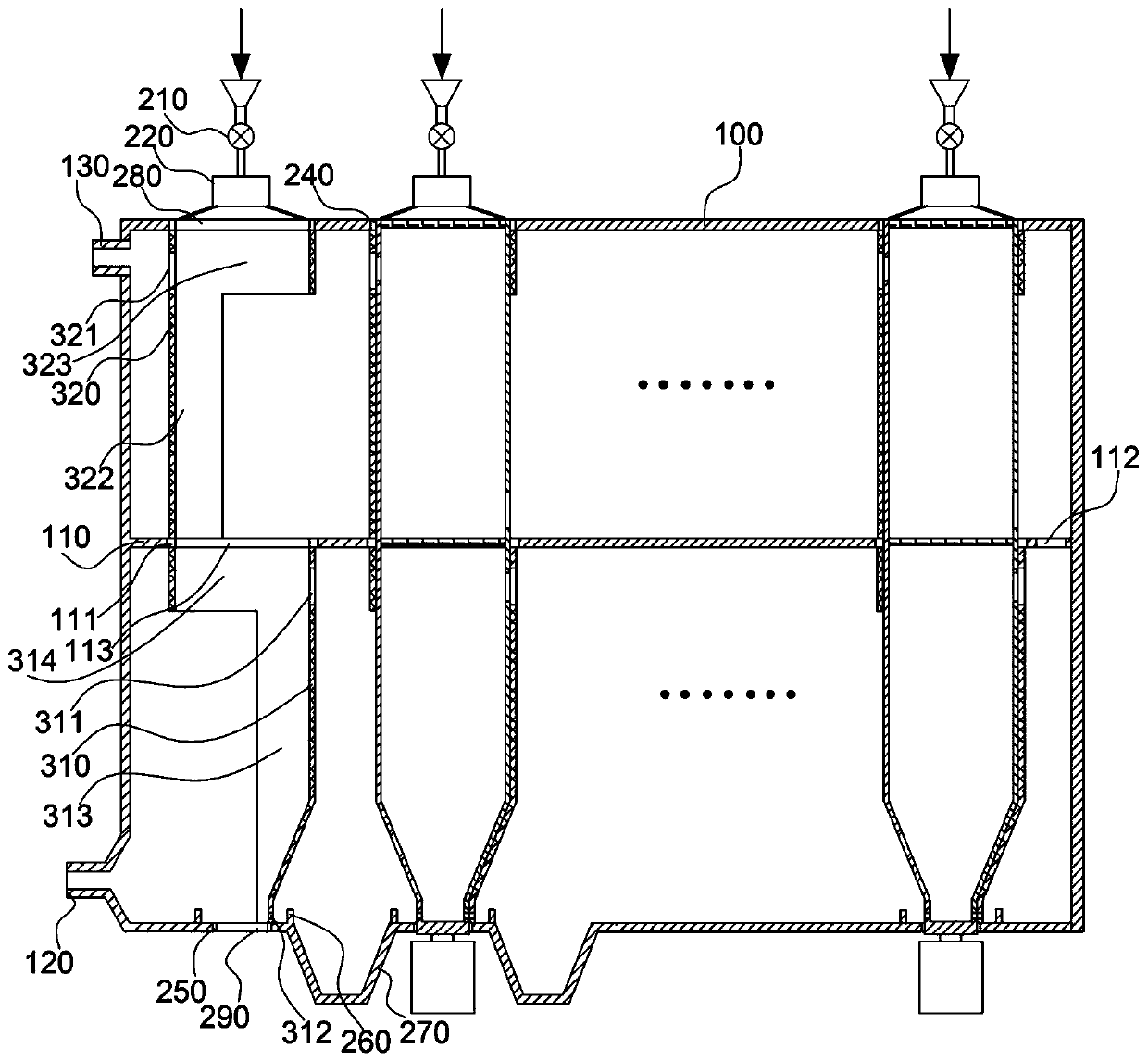

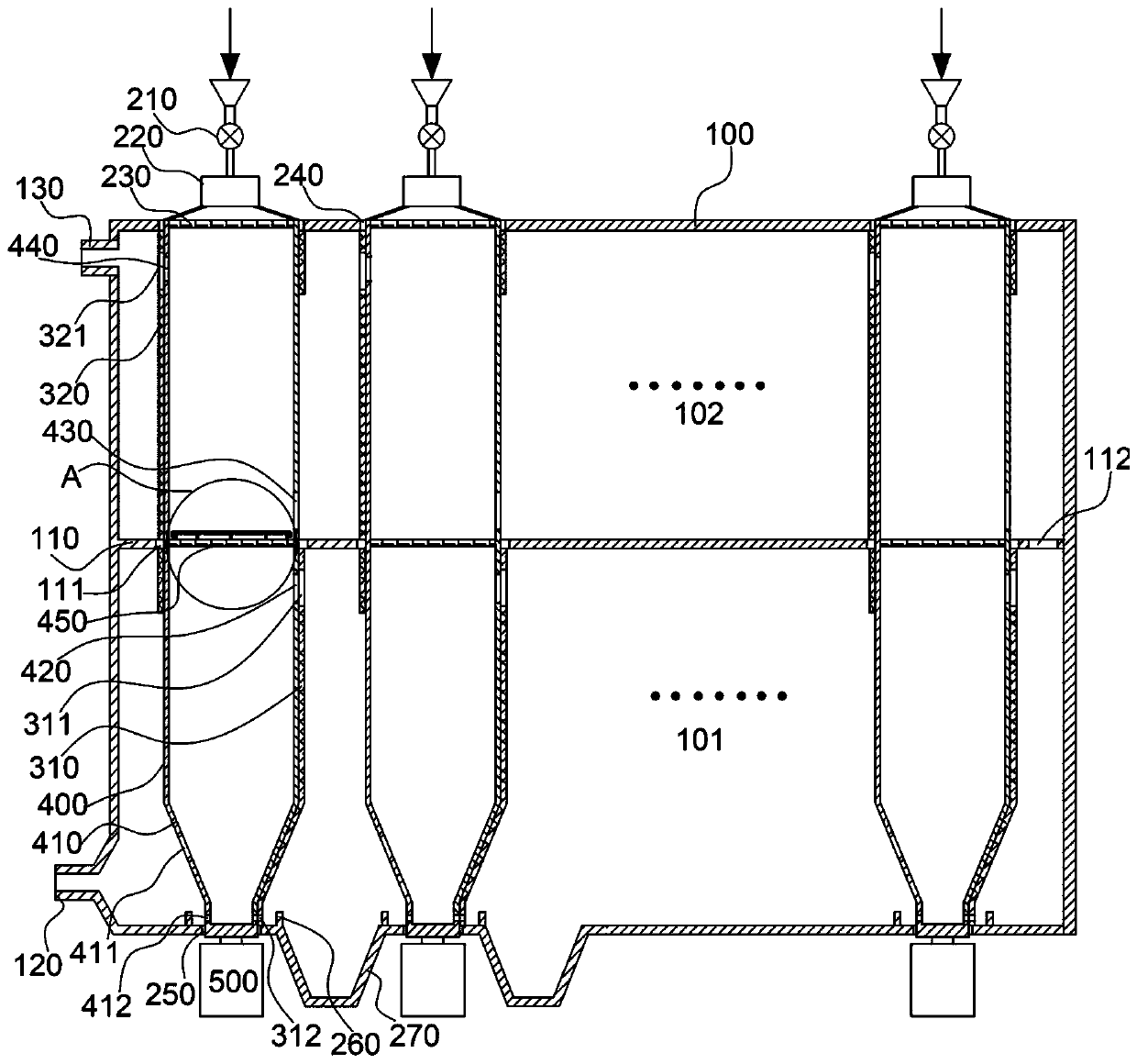

[0037] The processing device 100 is a hollow structure, and a layered partition 110 is arranged transversely at the height center of the processing device 100, and the processing device 100 is divided into a first chamber 101 and a second chamber 102. A through opening 112 is formed through the opening at one end to communicate with the first chamber 101 and the second chamber 102 at the first end.

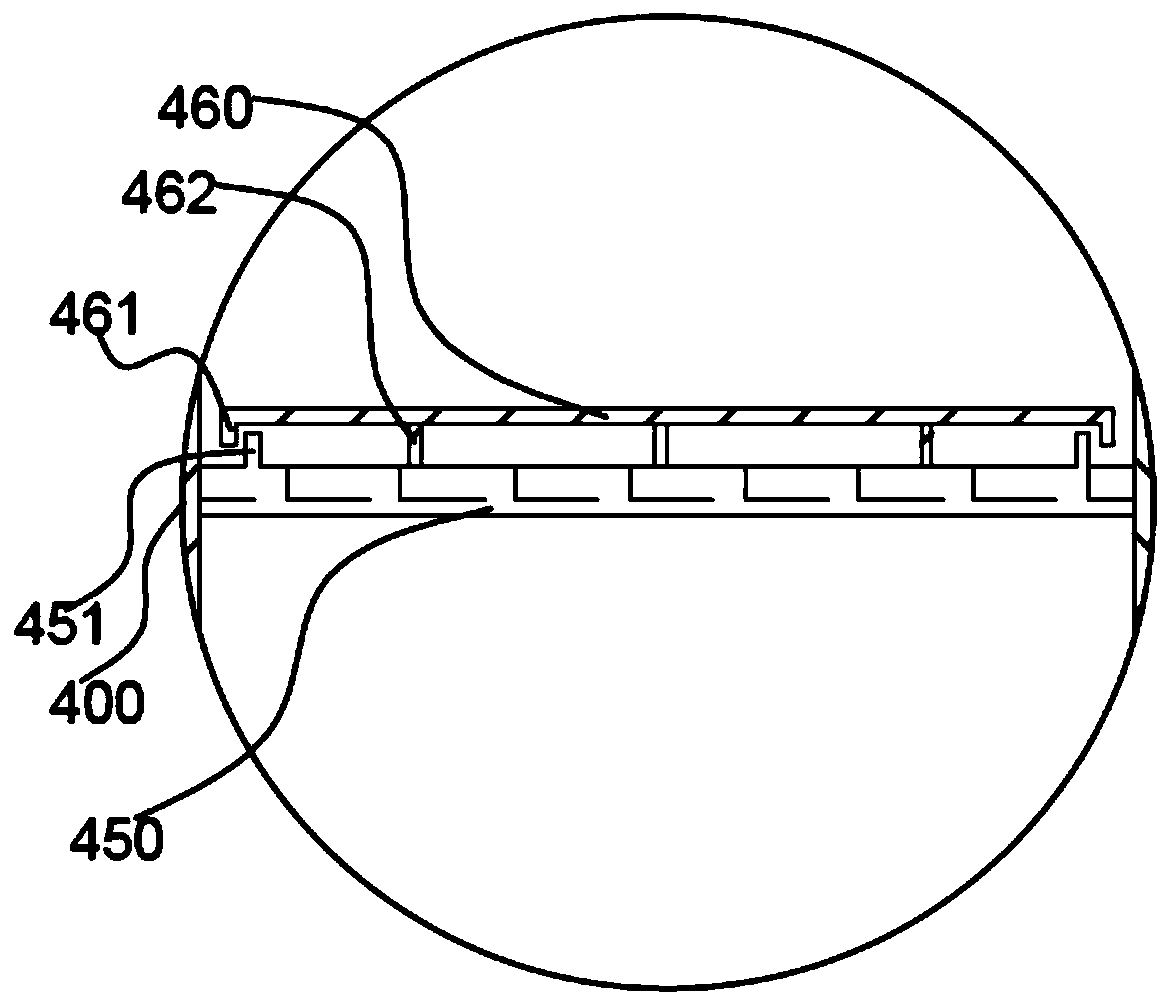

[0038] The spray tower 400 is a vertical hollow tower structure. The spray tower 400 runs through the layered partition 110 and is connected to the upper and lower ends of the processing device 100. Specifically, the layered partition 110 is provided with intervals There are a plurality of first through holes 113, a plurality of second through holes 290 are separated at the bottom of the processing device 100, and a plurality of third through holes 280 are separated at the top of the processing device 100, each through hole is circular, and the first The through hole 113 , the sec...

Embodiment 2

[0064] Such as Figure 4 and 5 As shown, the entire processing device 100 is provided with a multi-column cavity structure, that is, multiple groups of the processing systems described in Embodiment 1 are distributed in the processing device 100 at the same time, so as to improve the processing capacity of the entire processing system.

[0065] As mentioned above, the present invention specifically divides the treatment system into upper and lower levels by improving the structure and layout of the treatment system. Recycling for secondary use improves the utilization rate of the absorption liquid and the absorption rate of the waste gas, and effectively reduces the use of the absorption liquid and its treatment cost; the waste gas stays in the two-stage absorption system and reacts with the absorption liquid to absorb, increasing the waste gas Process the stroke to increase the absorption rate of exhaust gas; control the speed of the spray tower by detecting the concentratio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap