A Feed Superfine Pulverizer with Flexible Structure

An ultra-fine pulverizer, a flexible technology, applied in feed, grain processing, food science, etc., can solve the problem of inconvenient feeding in batches, and achieve moderate motor load, good pulverization effect, and small pulverized particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

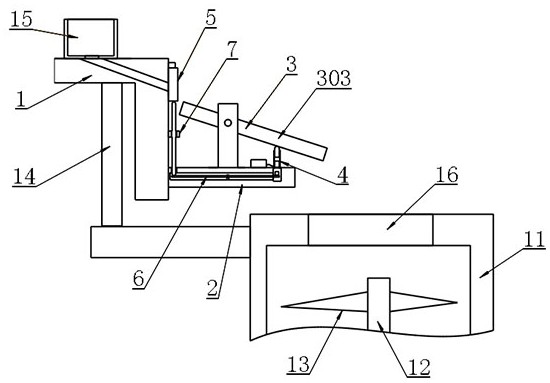

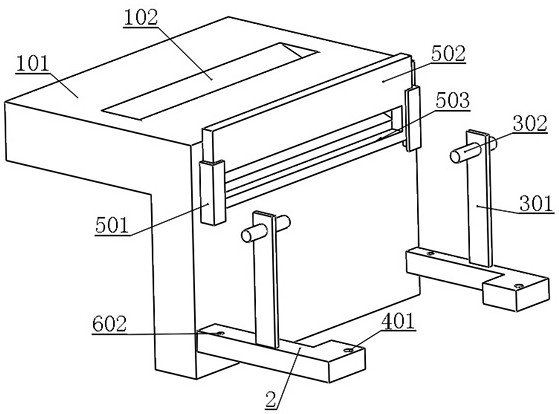

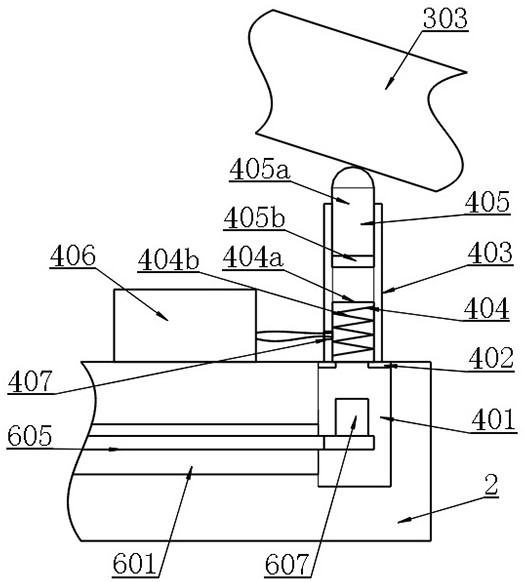

[0023] Example: as attached figure 1 , 2 , 3, 4 and attached Figure 5 As shown, a structure-flexible feed superfine pulverizer includes a pulverizer cavity (11), a rotating shaft (12) set in the pulverizer cavity (11) and driven by a motor, a pulverizer (13 ), the installation column (14) arranged at the upper position on the outer surface of the pulverizer cavity (11), and the material box (15) to be pulverized with openings in the lower part, and also includes the installation column (14) arranged on the installation column (14) ) on the L-shaped open-cavity plate (1), two L-shaped support plates (2) respectively arranged on both sides of the side of the L-shaped open-cavity plate (1), and hingedly arranged on the two L-shaped open-cavity plates (1) The rotary blanking plate unit (3) on the L-shaped support plate (2) and used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com