Longitudinal kicking and transverse patting type paper neatening device

A technology of paper sorting and horizontal shooting, which is applied in the stacking receiving device, thin material handling, transportation and packaging, etc., can solve the problems of unsatisfactory paper sorting effect, affecting the overall quality of paper packaging, etc., so as to improve the quality and work of paper packaging. Efficiency, high overall stability, effective effect of whole paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

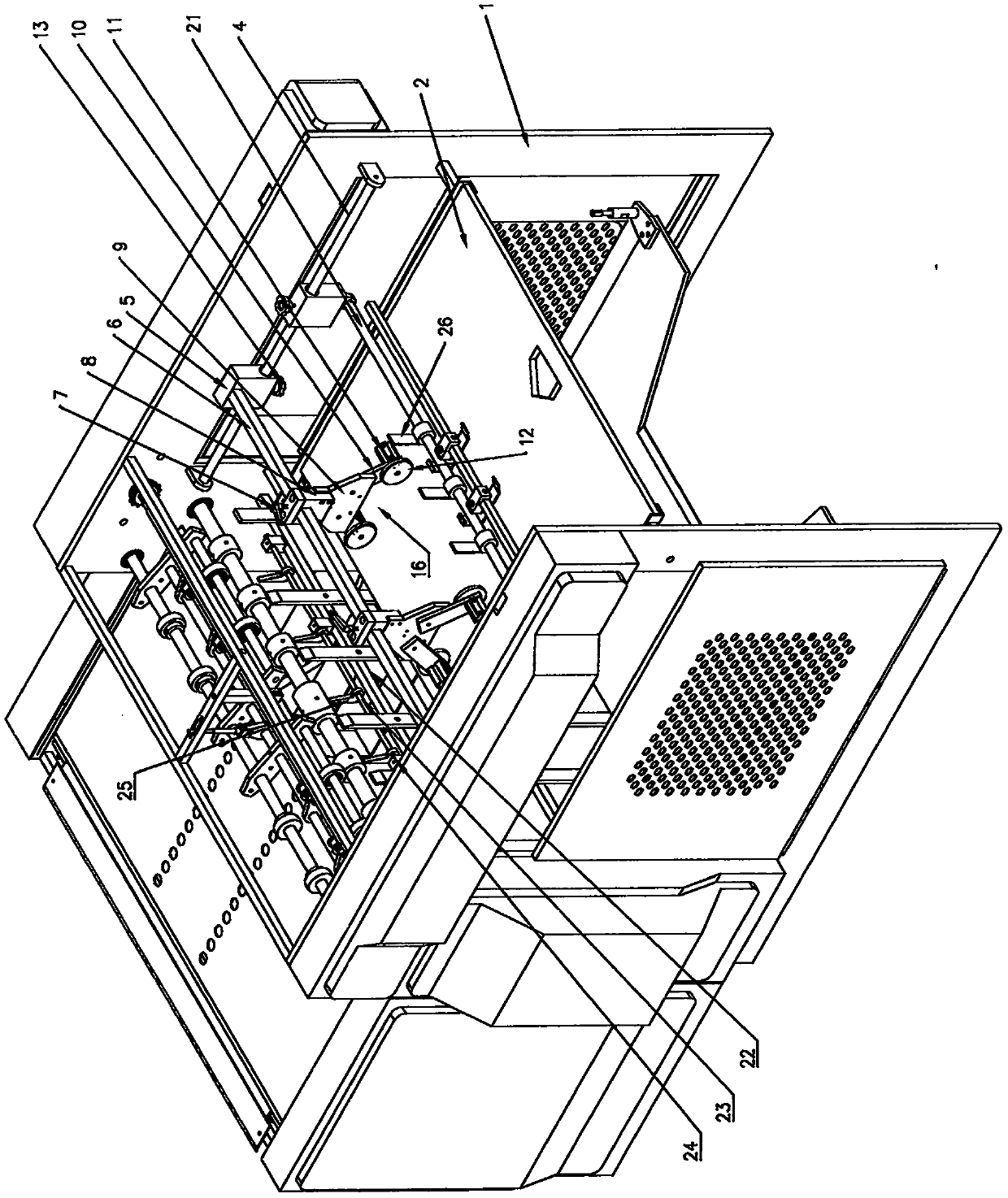

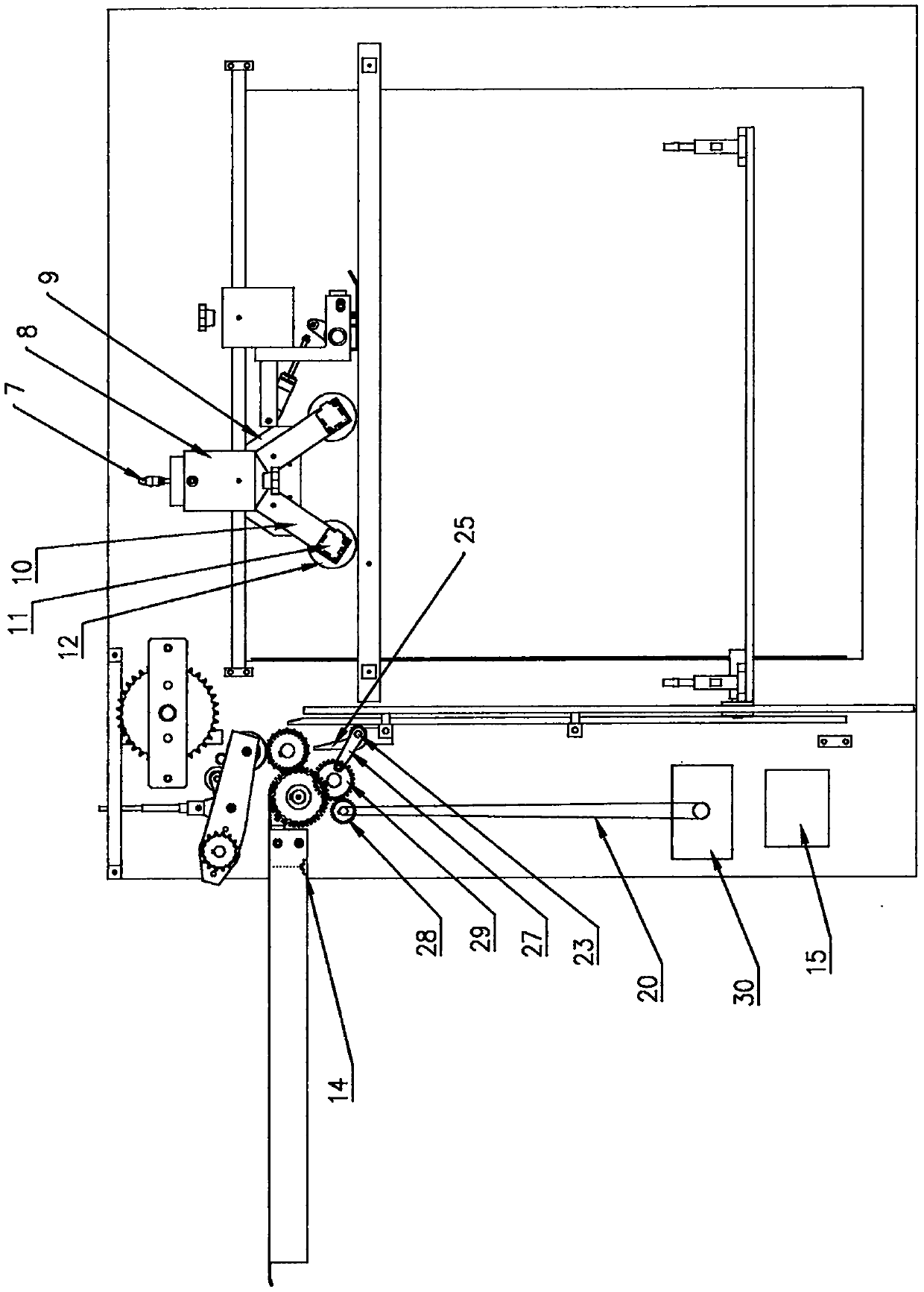

[0010] refer to figure 1 , figure 2 It can be known that the present invention is applied to the vertically kicking and horizontally clapping type paper sorting device of paper feeding equipment, including wallboard 1, front paper blocking block 26, front paper blocking strut 21, side sliding shaft 4, and the front paper blocking block 26 (several 1) installed on the front paper retaining strut 21, the side sliding shaft 4 is installed on both sides of the wallboard 1, on the wallboard 1, and at the paper output place, it is equipped with the front paper retaining support The support bar 22 corresponding to the position of the rod 21 (it is correspondingly parallel to the front paper stop support bar 21), the two sides of the support bar 22 are equipped with rotating rod fixing blocks 24, and the rotating rod fixing blocks 24 are equipped with rotating rods 23 , the rotating rod 23 is equipped with kicking paper blocks 25 (several pieces), the outer end of the rotating rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com