A kind of phosphate cement mortar proportioning method

A phosphate cement and mortar technology, applied in the fields of instruments, computational theoretical chemistry, informatics, etc., can solve the problems of unsuitable phosphate cement, retention, shortage, etc., achieve good operability and practicability, and avoid manpower and material resources Waste, simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 1. Design requirements

[0068] Requires the formulation of target intensity mean f MKPCM,m 35MPa potassium magnesium phosphate cement mortar, construction consistency C 0 30mm to 50mm.

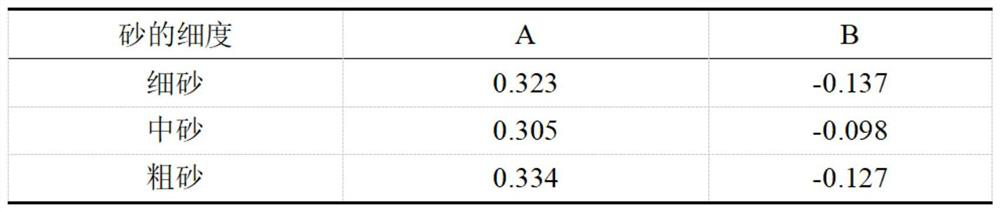

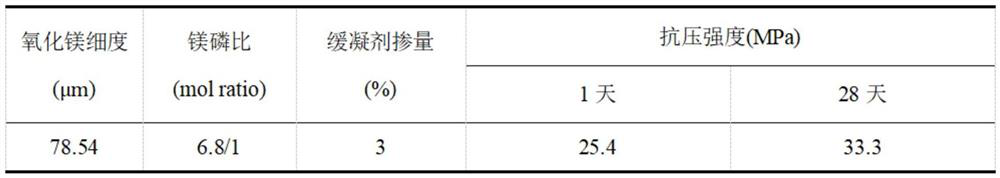

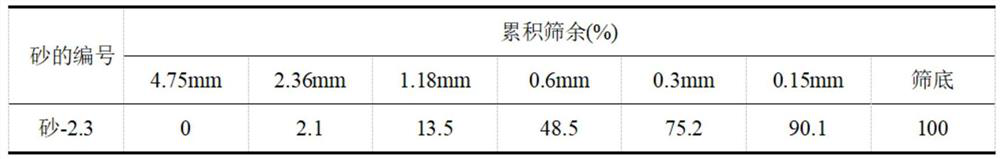

[0069] 2. Raw materials

[0070] The mix ratio and performance of the potassium magnesium phosphate cement used are shown in the following table. The magnesium oxide is made of dead-burned magnesium oxide sintered at a high temperature of about 1500 °C, and the density is 3.13g / cm 3 . The retarder is anhydrous sodium acetate. Magnesium phosphate cement mortar strength test is a group of plastic mortar mixed with a magnesium phosphate cement (phosphate + magnesium oxide + retarder) by mass, a Chinese ISO standard sand, and a water-binder ratio of 0.21. Make a 40mm×40mm×160mm prism test body, cured for 2 hours in an environment with a temperature of 20°C±2°C and 60%±5%RH, and then remove the mold, and then continue to cure until the strength test. The compressive strength test refe...

Embodiment 2

[0102] 1. Design requirements

[0103] Requires the formulation of target intensity mean f MKPCM,m Potassium magnesium phosphate cement mortar of 55MPa, construction consistency C 0 40mm ~ 60mm.

[0104] 2. Raw materials

[0105] The mixture ratio and performance of the potassium magnesium phosphate cement used are shown in the following table. The magnesium oxide is made of dead-burned magnesium oxide sintered at a high temperature of about 1500 °C, and the density is 3.29g / cm 3 . The retarder is anhydrous sodium acetate. Magnesium phosphate cement mortar strength test is a group of plastic mortar mixed with a magnesium phosphate cement (phosphate + magnesium oxide + retarder) by mass, a Chinese ISO standard sand, and a water-binder ratio of 0.21. Make a 40mm×40mm×160mm prism test body, cured for 2 hours in an environment with a temperature of 20°C±2°C and 60%±5%RH, and then remove the mold, and then continue to cure until the strength test. The compressive strength tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com