Pressing and leveling device applied to cement pouring

A cement and equipment technology, applied in the field of compaction and leveling equipment for cement pouring, can solve the problems of cement mixture overflowing to other places, inconvenient handling, waste of cement mixture, etc., and achieve good leveling effect and novel design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

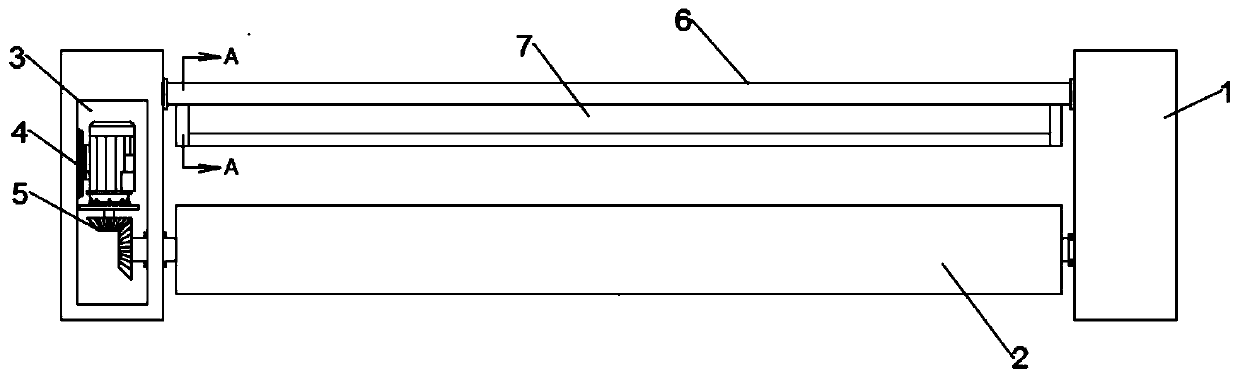

[0023] see figure 1 , 4 And 5, in the embodiment of the present invention, a kind of compacting and leveling equipment for cement pouring includes a moving receiving block 1 and a pressure roller 2; two moving receiving blocks 1 are symmetrically arranged, and the pressing roller 2 is arranged on two moving between the receiving blocks 1, and the rotating shaft at one end of the pressing roller 2 is connected to the driving assembly in the transmission chamber 3 on one of the moving receiving blocks 1, and the driving assembly drives the pressing roller 2 to rotate, so that the plane after cement pouring Compression processing, there is a collection tank between the two moving receiving blocks 1, the front end of the collection tank (ie, the moving direction of the collection tank) is hinged with a movable plate 8, and the two ends of the movable plate 8 are connected to the side walls of the collection tank. The arc-shaped movable groove 9 is slidingly connected, and when th...

Embodiment 2

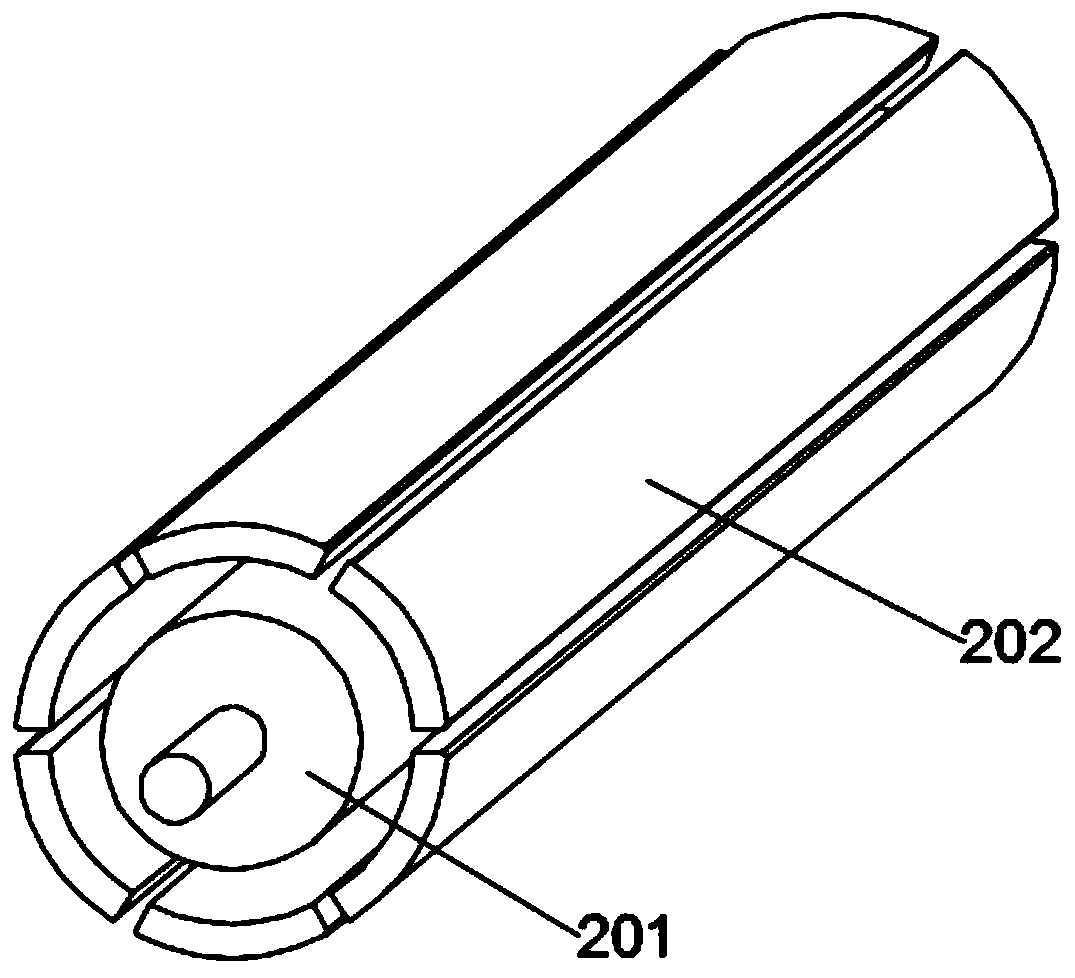

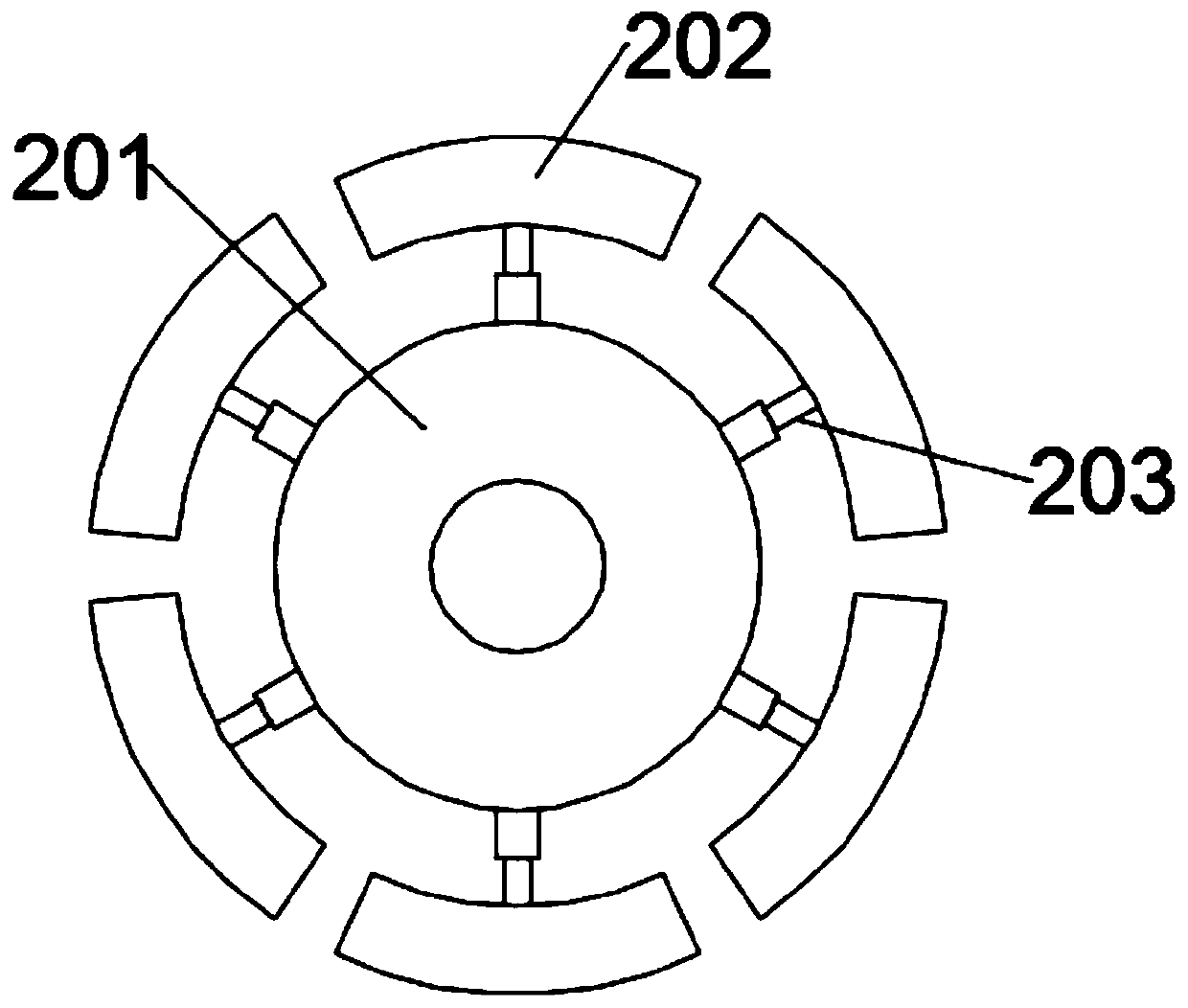

[0029] see figure 2 and 3 , in order to increase the pressing effect of the pressure roller 2 during the working process, the present invention also proposes another embodiment to improve the application during the specific implementation process. Specifically, the pressure roller 2 includes a receiving roller 201, an arc-shaped pressure plate 202 and elastic telescopic rods 203. There are multiple arc-shaped pressing plates 202, and the plurality of arc-shaped pressing plates 202 are arranged on the outside of the receiving roller 201 in a circumferential direction. Each of the arc-shaped pressing plates 202 passes through at least two elastic telescopic rods. 203 is connected with receiving roller 201, realizes the compression treatment of arc-shaped pressing plate 202 to the cement pouring surface by the elastic force of elastic telescopic rod 203, and the press effect is good.

Embodiment 3

[0031] see Figure 6 , in order to further facilitate the promotion of the mobile receiving block 1, the present invention also proposes another embodiment to improve the present application. Specifically, the upper end of the mobile receiving block 1 is fixed with a handle 11, and the setting of the handle 11 facilitates work. Person's grip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com