Extractor hood

A range hood and hood technology are applied in the field of range hoods, which can solve the problems of long distance between the smoke inlet and the cooker, inability to effectively suck and discharge, and achieve the effects of reducing the escape of oil fume, improving the effect of collecting smoke, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples illustrate the invention, but the invention is not limited by these examples. Modifications to the specific implementation of the present invention or equivalent replacement of some technical features without departing from the spirit of the present invention should be included in the scope of the technical solution claimed in the present invention.

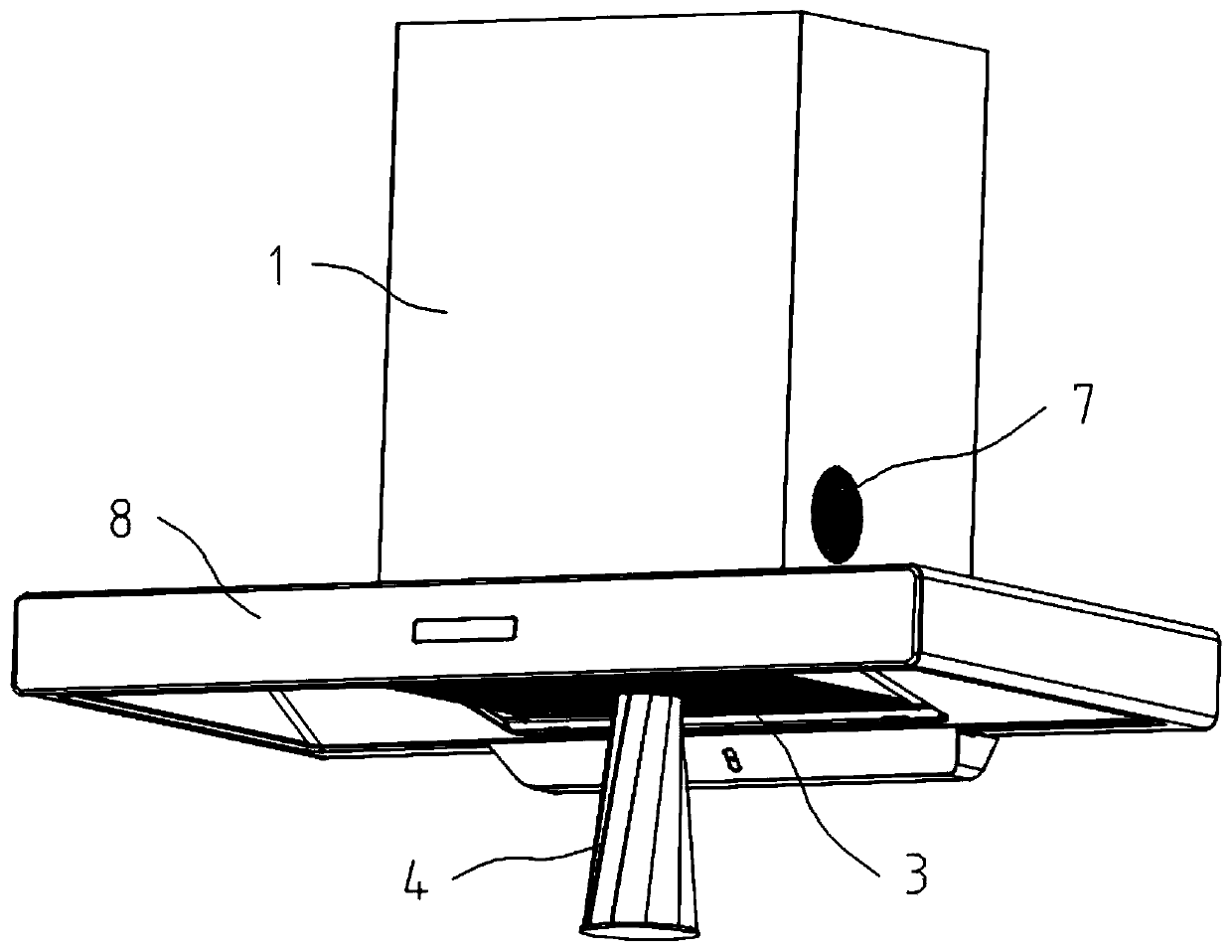

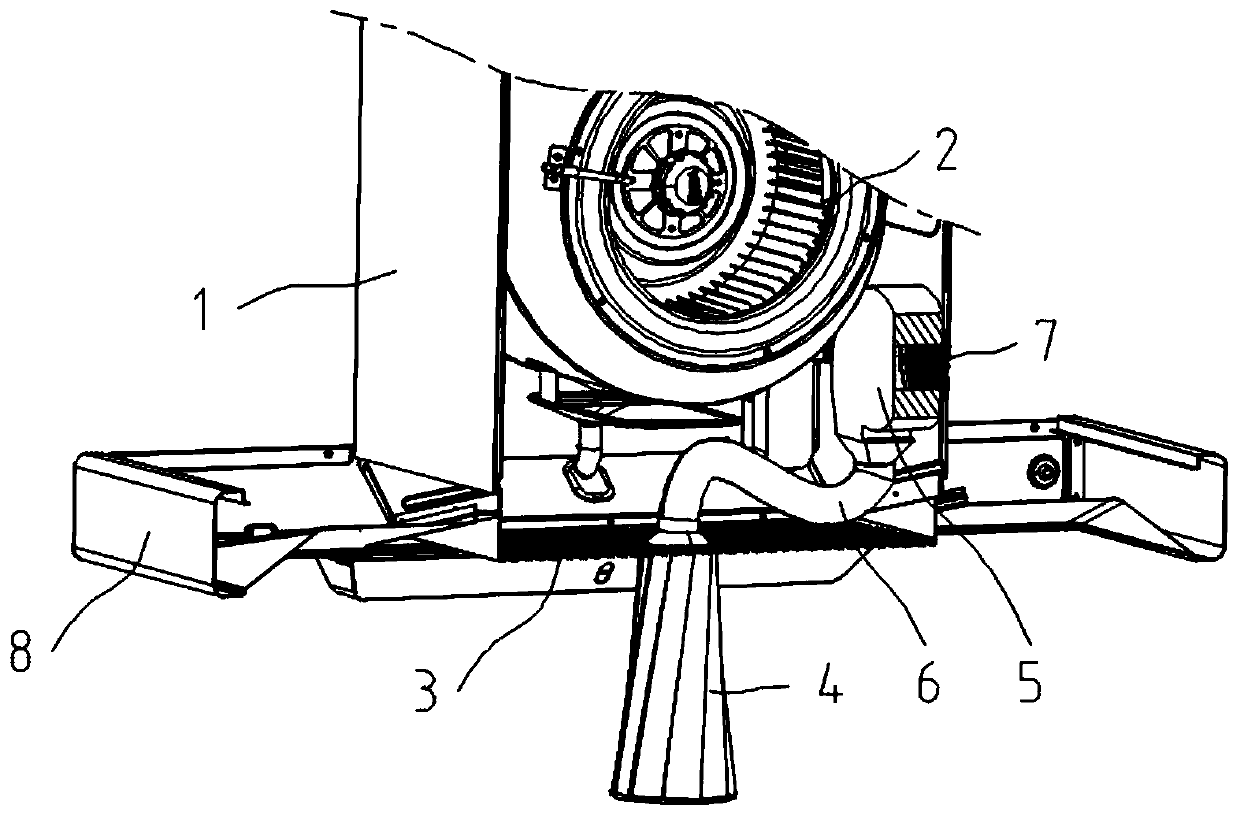

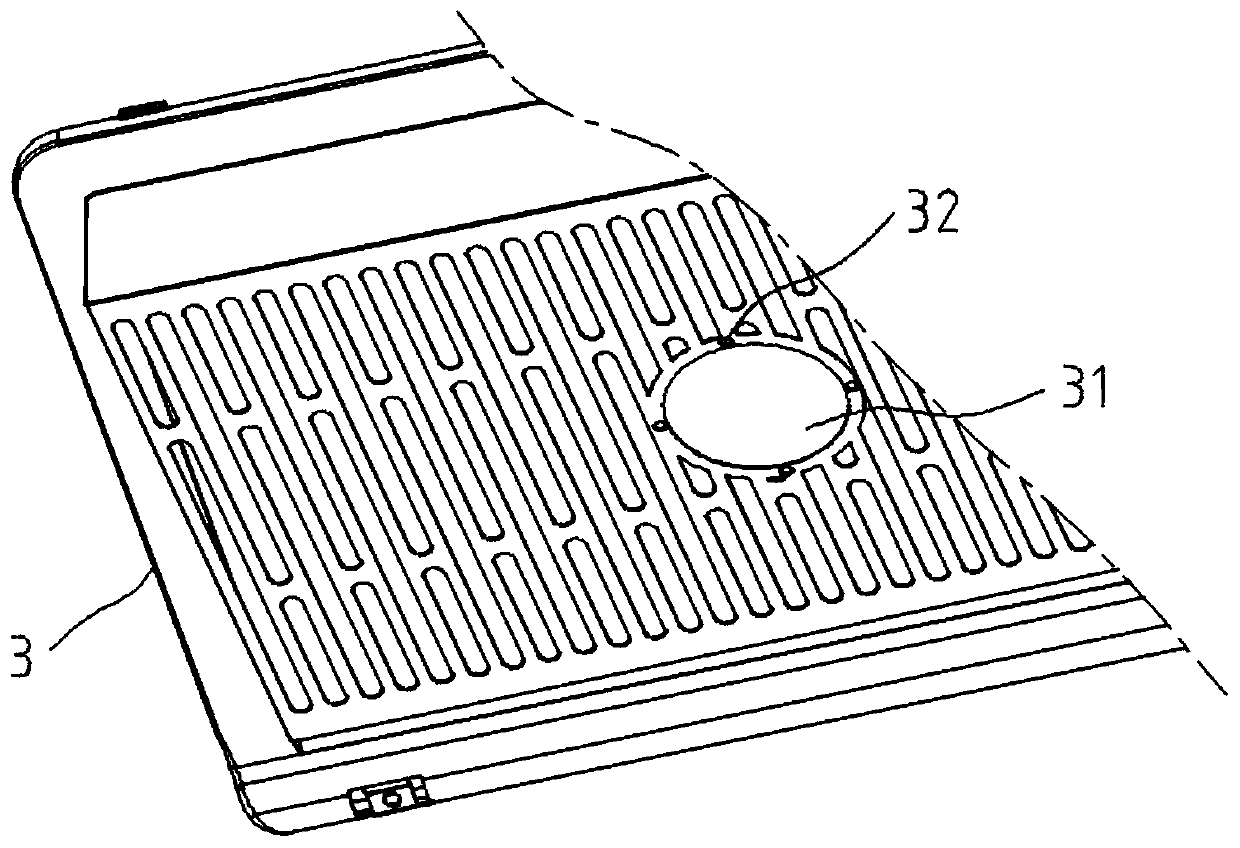

[0027] Such as Figure 1-2 As shown, a range hood in this embodiment includes a hood casing 1 , a first fan assembly 2 , an oil screen assembly 3 , a swirling flow generating device 4 , a second fan assembly 5 and a smoke collection hood 8 . The hood casing 1 has a smoke inlet, the oil screen assembly 3 is arranged at the smoke inlet, and the first fan assembly 2 is arranged inside the hood casing 1 . The swirl flow generating device 4 is provided with an air inlet 401 and its side wall is provided with several air outlets 402 for forming swirl flow. The several air outlets 402 can eject rotating ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap