Screen capable of eliminating laser speckles by vibration

A laser speckle and vibration elimination technology, applied in optics, optical components, image communication, etc., can solve the problems of high noise, inconvenient installation and debugging, etc., and achieve the effect of easy installation and debugging, elimination of laser speckle, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The technical scheme of the present invention is illustrated in detail below.

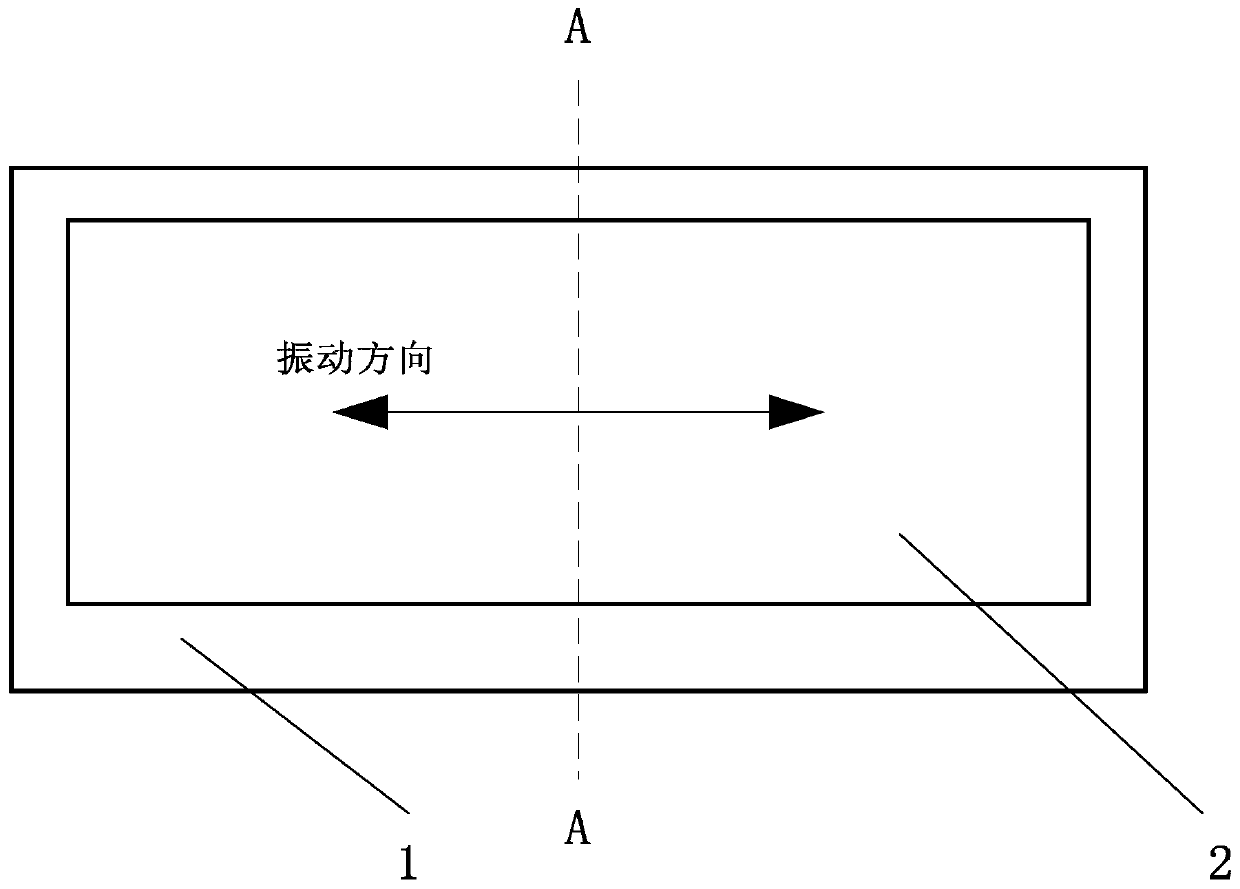

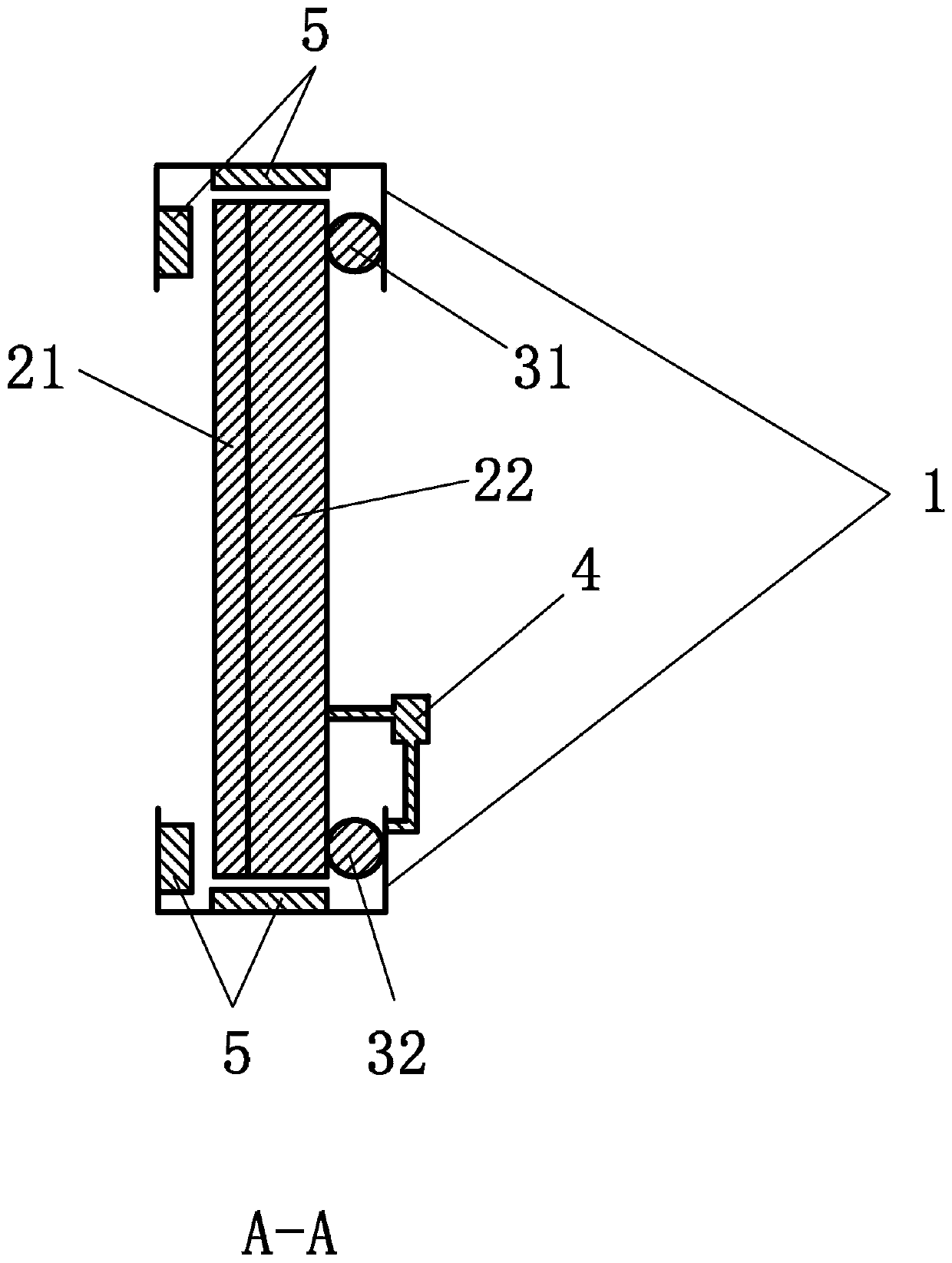

[0035] In this example, the screen that eliminates laser speckle by vibration, such as figure 1 and figure 2 As shown, it includes a screen frame 1, a rigid display surface component 2, a guide rail mechanism 1 31, a guide rail mechanism 2 32, an actuating component 4 and an elastic body 5, wherein the rigid display surface component 2 is composed of an optical display film layer 21 and a rigid support backplane 22 composite.

[0036] The screen frame 1 adopts a slotted design, the rigid display surface part 2 is located in the screen frame 1, the actuation part 4 is respectively connected with the screen frame 1 and the rigid support backplane 22, and the actuation part 4 is located on the back side of the rigid display surface part , which is located on one side of the rigid support backplane 22 . The upper back of the rigid support backplane 22 is connected to the groove of the screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com