Automatic detection and defect identification method for power grid wire clamp and device

An automatic detection and defect recognition technology, applied in character and pattern recognition, image data processing, instruments, etc., can solve problems such as affecting work efficiency, long model update cycle, slow model training, etc., and achieve the effect of improving detection and recognition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

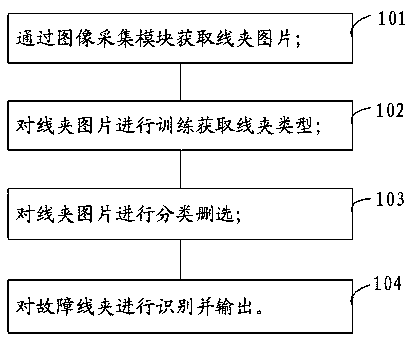

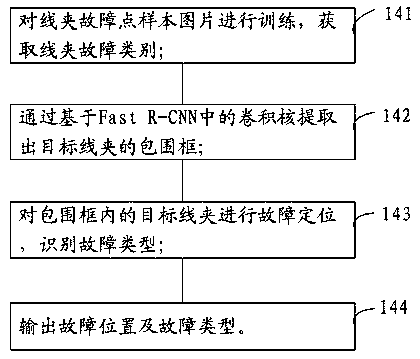

[0047] like figure 1 As shown in the figure, it is a flow chart of a method for automatic detection and defect identification of power grid clamps proposed by the present invention.

[0048] refer to figure 1 , a method for automatic detection and defect identification of wire clips in a power grid, comprising the following steps:

[0049] Step 101, obtain the wire clip picture through the image acquisition module;

[0050] Step 102, train the wire clip picture to obtain the wire clip type;

[0051] Step 103, classify and delete the clip pictures;

[0052] Step 104, identifying and outputting the fault line clamp.

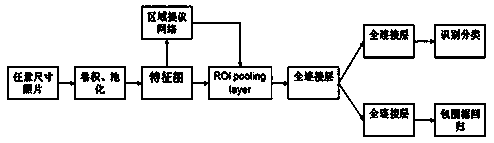

[0053] In the embodiment of the present invention, the image acquisition module is used to collect images of the clamps on the transmission line, and the Faster R-CNN technology is used to train the pictures of the clamps to obtain the type of clamps and realize the classification of the types of clamps. The training and identification of the fault line clips ...

Embodiment 2

[0078] Based on the same inventive concept as the method for automatic detection and defect identification of power grid clamps in the foregoing embodiments, the present invention also provides an automatic detection and defect identification device for power grid clamps.

[0079] see Figure 5 , an automatic detection and defect identification device for grid wire clips, comprising:

[0080] Image collection module 201, used to obtain the wire clip picture;

[0081] Wire clip type training module 202, for training the wire clip picture to obtain the wire clip type;

[0082] The wire clip classification module 203 is used to classify and delete the wire clip pictures;

[0083] The clamp fault detection module 204 is configured to identify and output faulty clamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com