Anti-swirl inclined-conveying-type industrial material stirring machine and working method thereof

An anti-vortex, conveying technology, used in mixers with rotary stirring devices, chemical instruments and methods, mixers, etc., can solve problems such as low efficiency, uneven mixing of industrial materials, material eddy current, etc., to ensure high efficiency. , Guarantee thoroughness, prevent the effect of eddy current phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

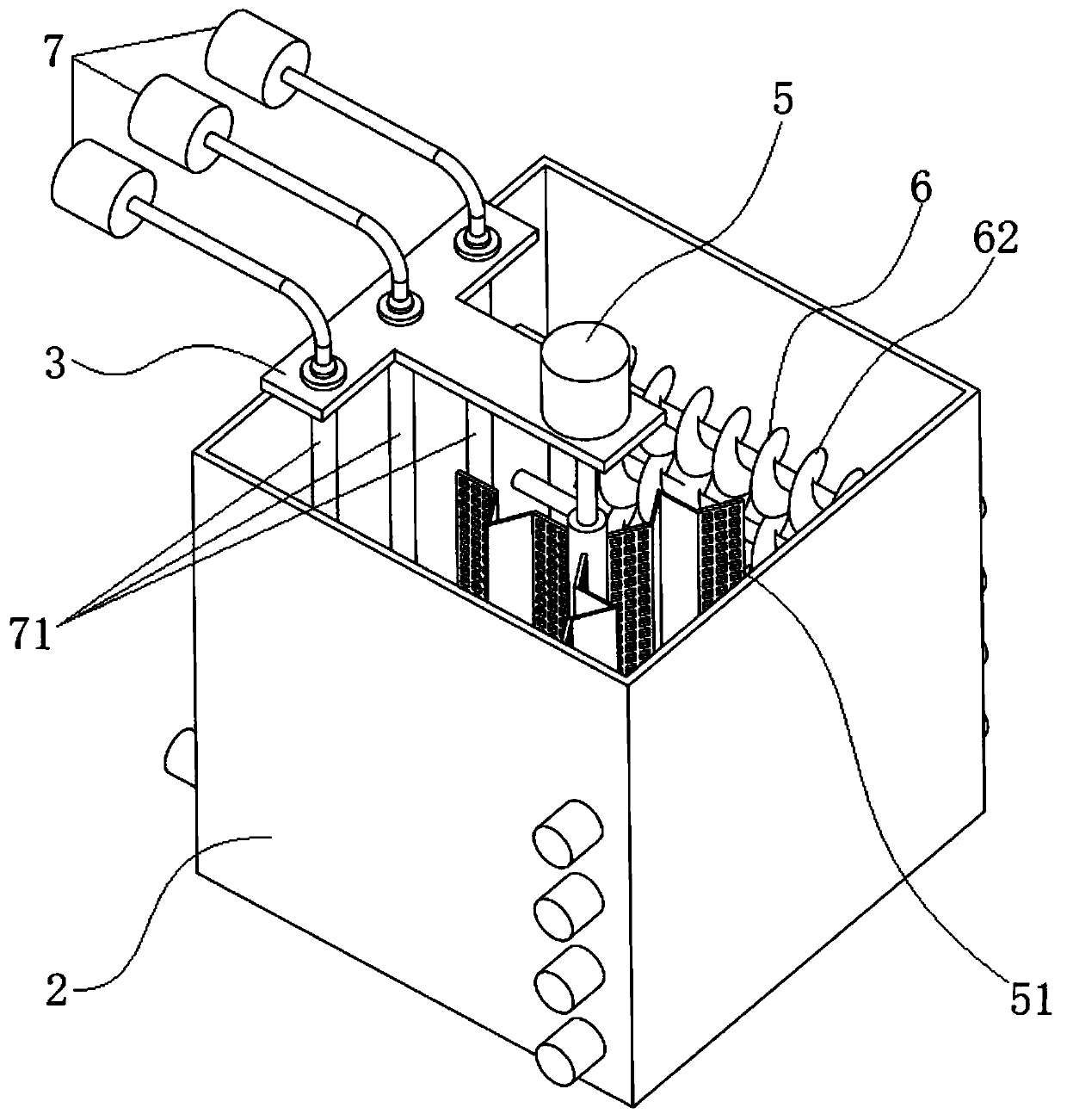

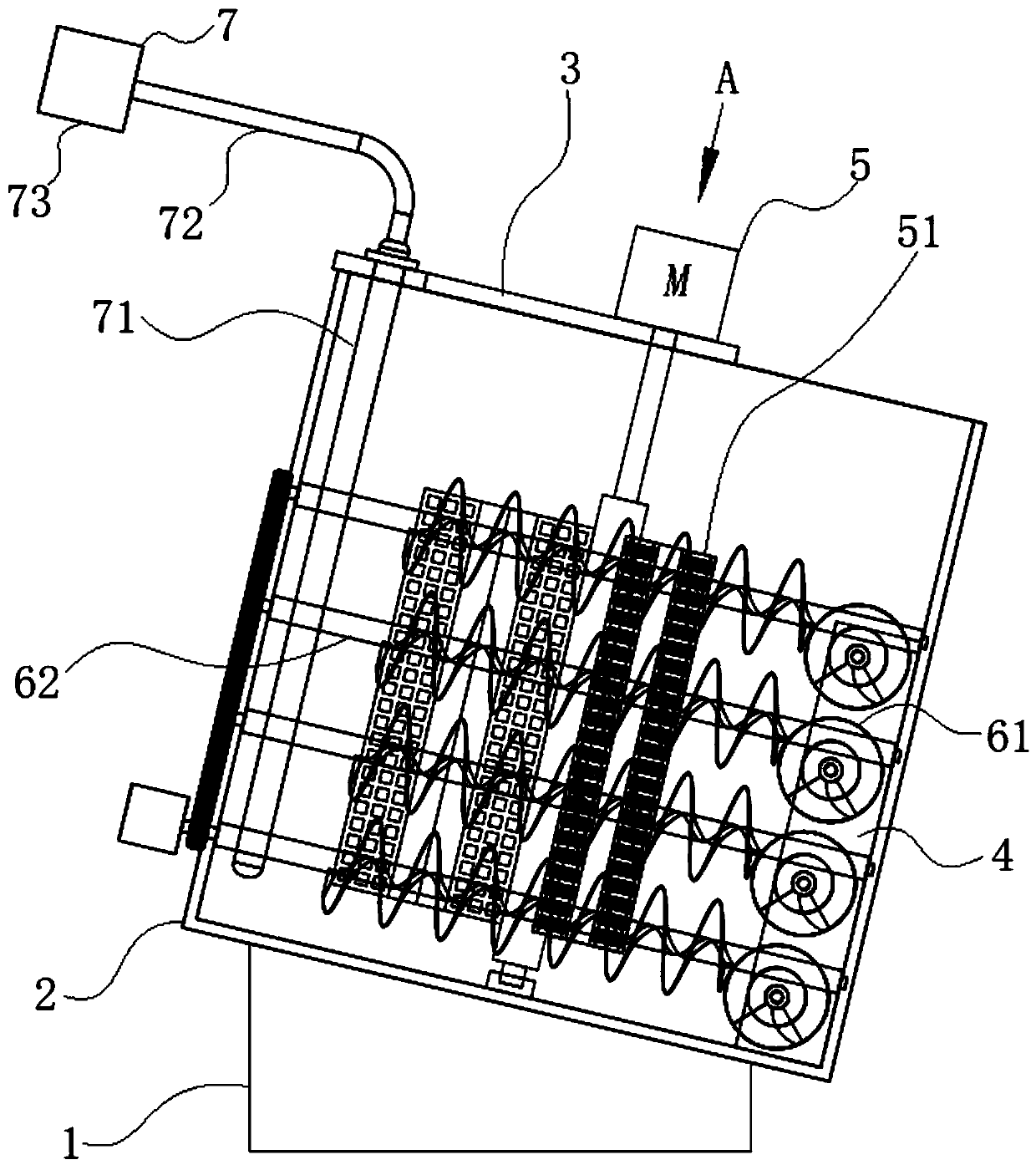

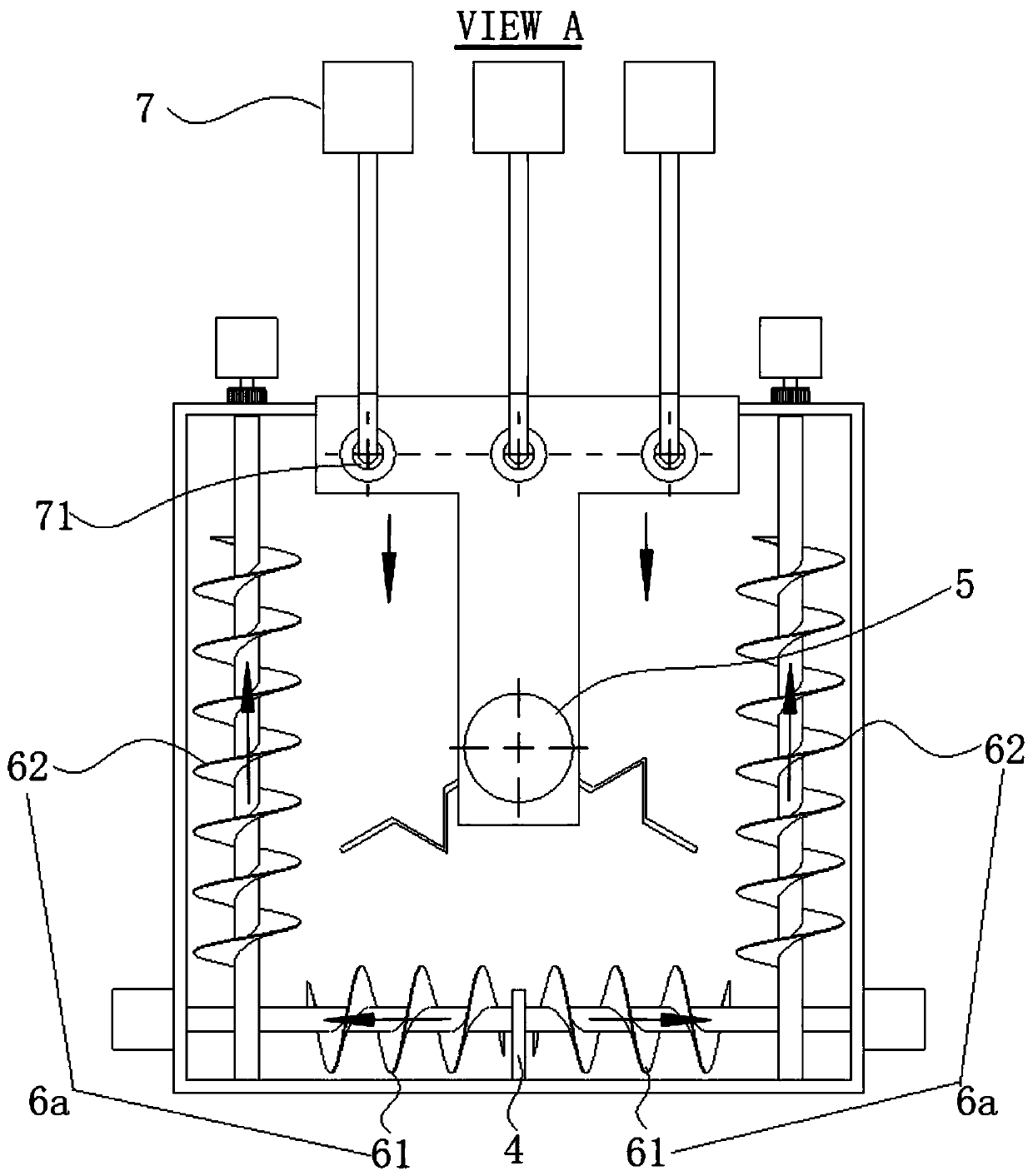

[0028] attached image 3 to attach figure 2 The A-direction view, as attached figure 1 to attach image 3 As shown, the anti-eddy current inclined conveying industrial material mixer includes a base 1 and a mixing box 2; the mixing box 2 is a rectangular tank structure with an open top, which is supported by the base 1 and is set in an inclined state as a whole; it also includes a material mixing unit 5 and a material conveying unit 6; the top opening of the stirring box 2 is provided with a mounting plate 3, the material stirring unit 5 is installed on the mounting plate 3, and the material rotating stirring portion 51 of the material stirring unit 5 is located inside the stirring box 2 center; the material conveying unit 6 includes two material horizontal conveying units 61 and two material inclined conveying units 62, and the inner side of the short end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com