Fabric skew detection method based on image analysis

A detection method and weft skew technology, applied in the field of fabric weft skew detection, can solve the problems of complex texture patterns, inability to detect effectively, and poor detection effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in further detail below in conjunction with the accompanying drawings.

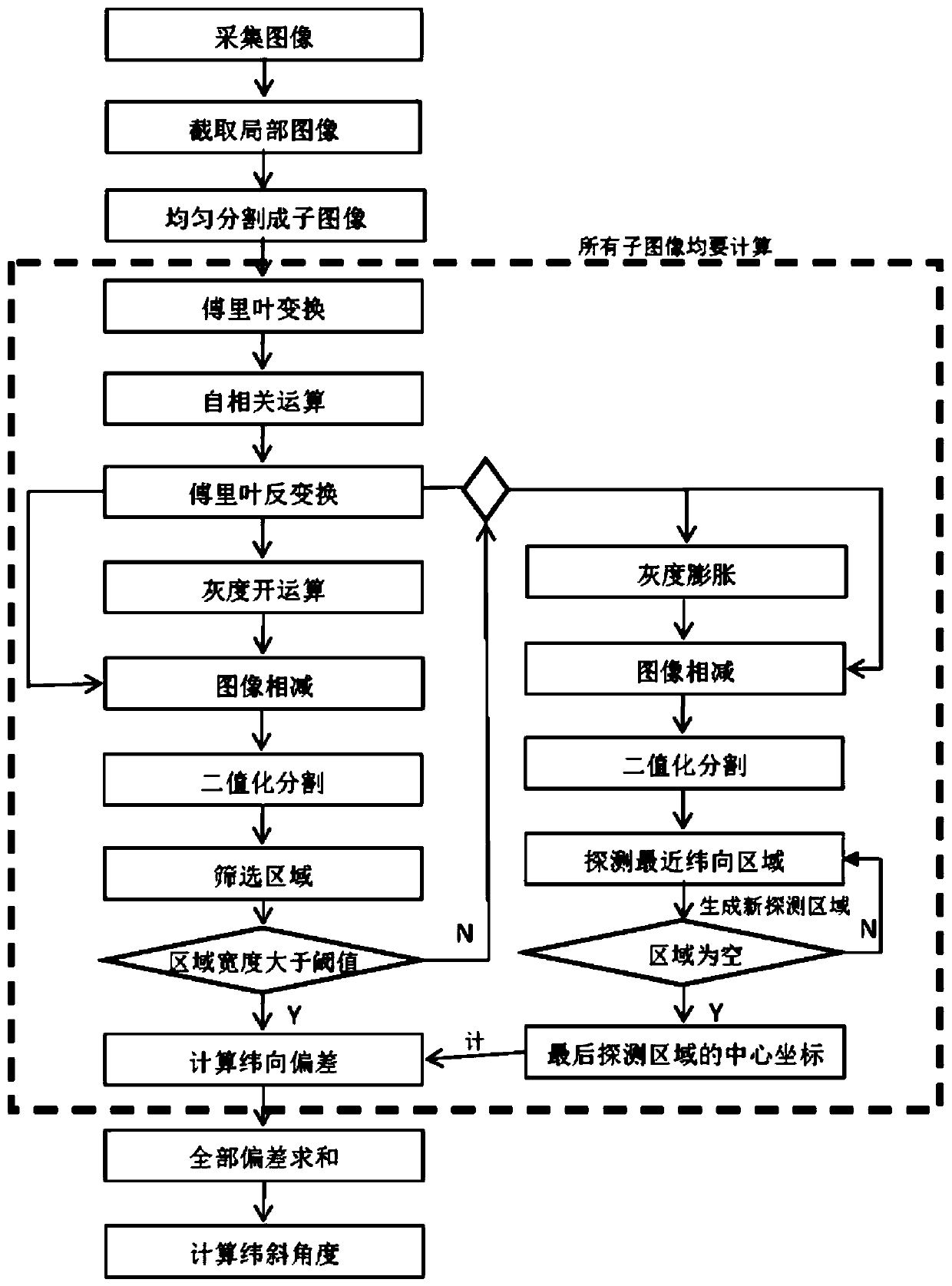

[0065] The present invention proposes a figure 1 A new method for weft skew detection of fabrics is shown by image analysis. Based on the principle of autocorrelation in image analysis, this method can quickly and accurately detect latitude results in real time, including the following steps:

[0066] 1. Use a CCD industrial camera to collect the fabric texture image Image, the image height is h, and the width is w, such as figure 2 shown.

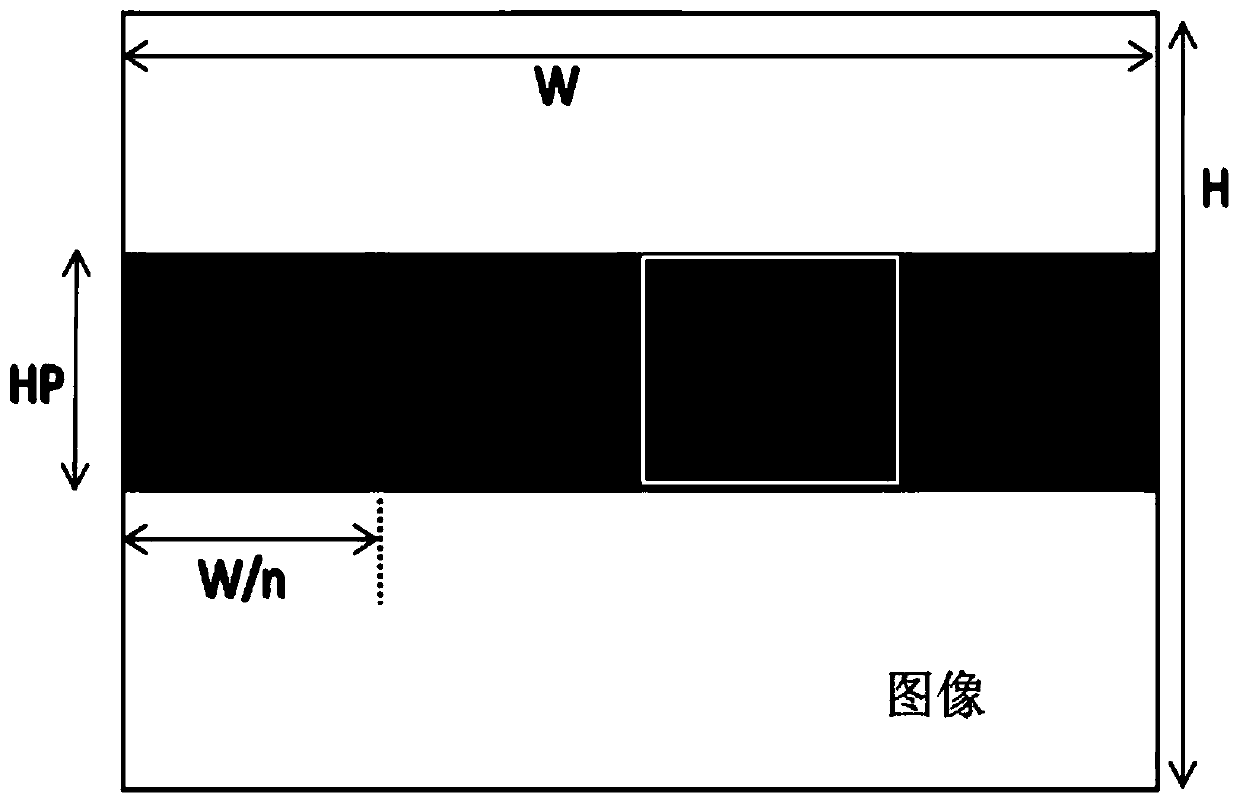

[0067] 2. Intercept a part of the image Image to obtain ImageP, the image ImageP has a height of N and a width of w.

[0068] Here N can generally be selected as 1 / 8 to 1 / 2 of h, the starting coordinate of the intercepted image in the Y direction is (h-N) / 2, the ending coordinate is (h+N) / 2, the starting coordinate in the X direction is 0, and the ending coordinate is The coordinates are w-1.

[0069] 3. The image I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com