Terahertz time domain spectrum technology-based plastic film thickness detection device and method

A terahertz time domain, plastic film technology, used in the field of non-destructive and rapid detection of plastic films, can solve the problems of poor detection accuracy of plastic film thickness, easy to be affected by the environment, low measurement accuracy, etc., to suppress the influence caused by multiple reflections , to ensure sensitivity, to overcome the effect of low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

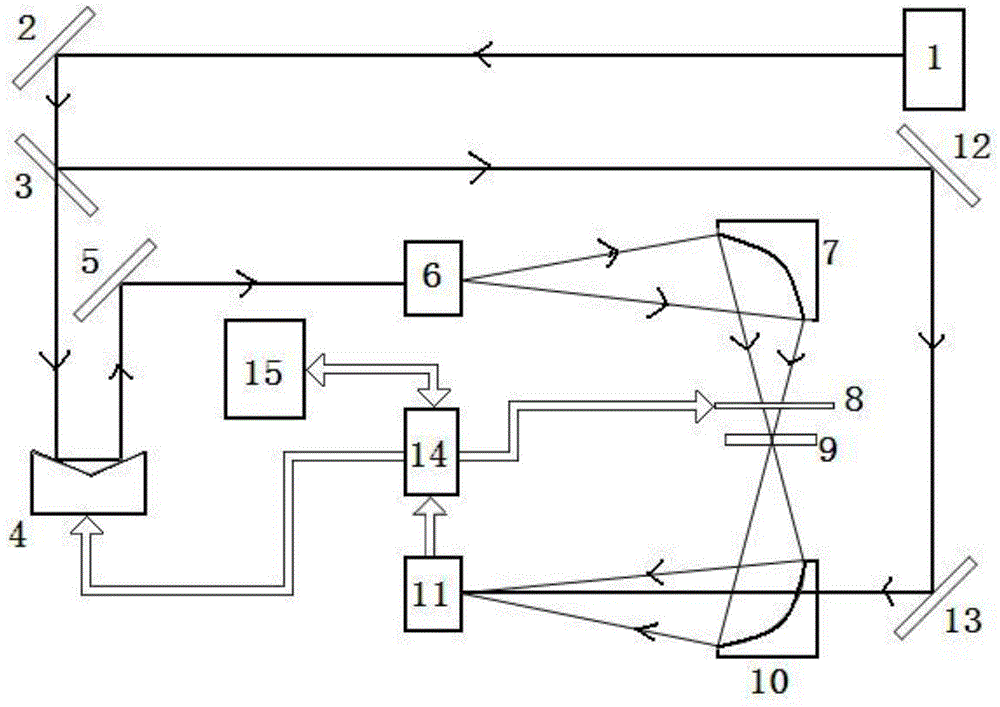

[0041] Such as figure 1 As shown, a plastic film thickness detection device based on terahertz time-domain spectroscopy technology includes: a femtosecond laser 1, a first mirror 2, a beam splitter 3, an optical delay line 4, a second mirror 5, a Hertz transmitter 6, first parabolic mirror 7, IR filter 8, sample stage 9, second parabolic mirror 10, terahertz detector 11, third mirror 12, fourth mirror 13, terahertz time domain system control Device 14 and computer 15;

[0042] The femtosecond laser 1 emits laser light that passes through the first reflector 2 and irradiates the beam splitter 3, and is divided into two beams, one of which passes through the optical delay line 4 and the second reflector 5 and then irradiates the terahertz emitter 6 Terahertz waves are generated, and the generated terahertz waves are focused after being passed through the first parabolic mirro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com