Small-size filter device having convenience in pipe cleaning

A pipeline cleaning and filtering device technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as troublesome maintenance, complex structure, troublesome disassembly, etc., to achieve convenient maintenance, good filtering effect, The effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

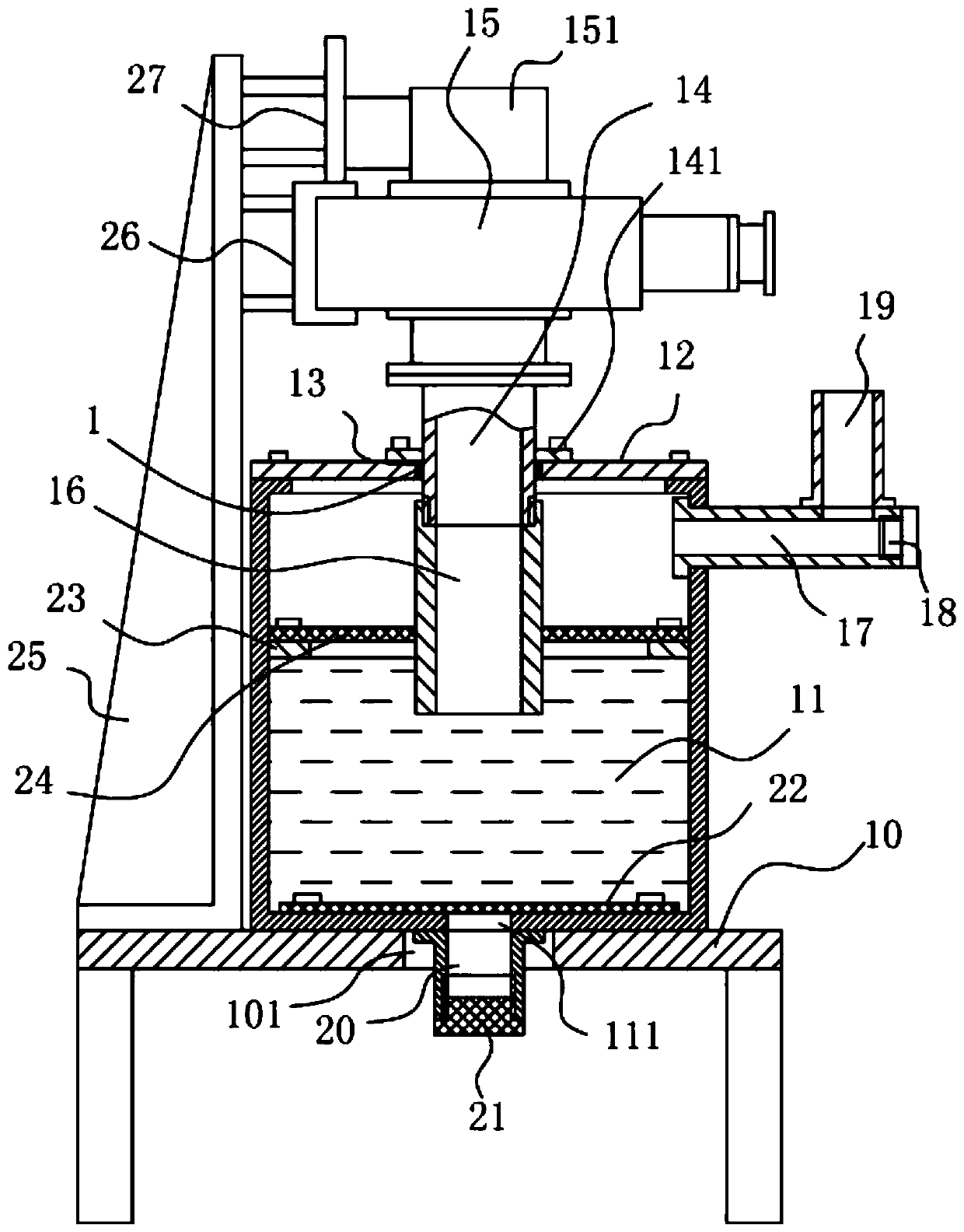

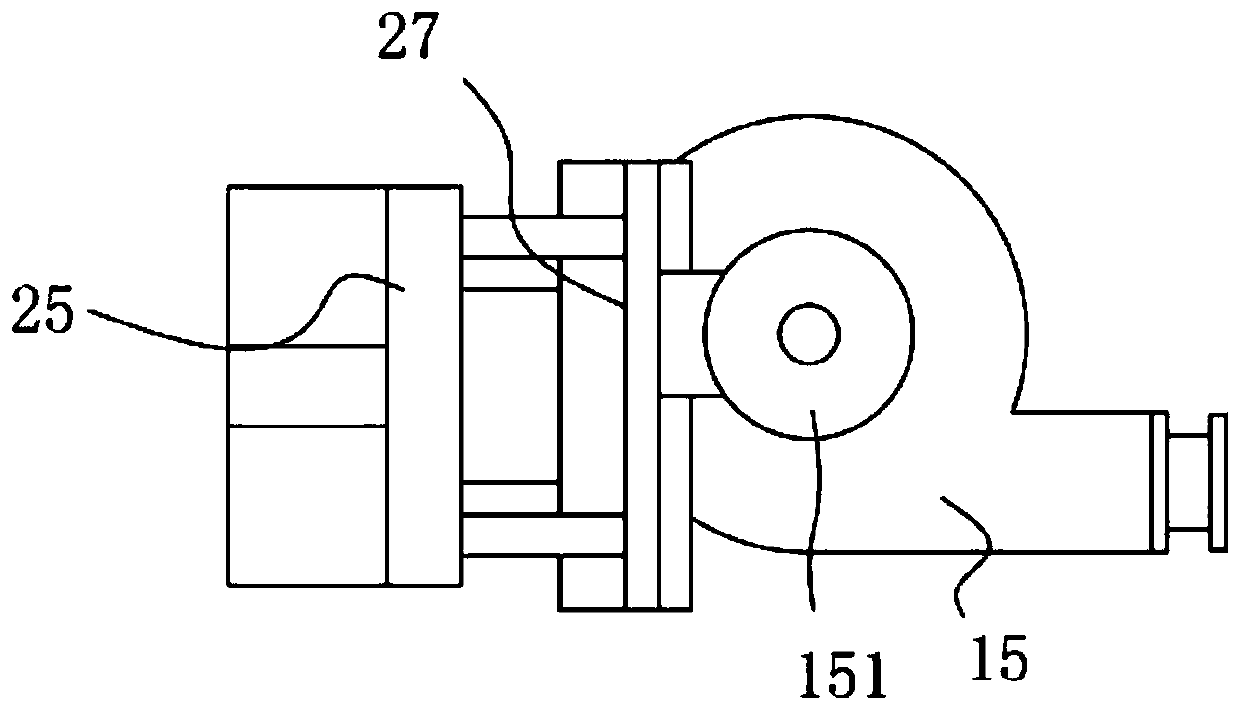

[0018] Example: see Figure 1 to Figure 2 As shown, a small filter device with convenient pipeline cleaning includes a frame 10, a main barrel body 11 is fixed on the top surface of the top plate of the frame 10, and an upper cover plate 12 is fixed on the top surface of the main barrel body 11. The middle part of the upper cover plate 12 has a central through hole 13, the air inlet pipe 14 is inserted into the central through hole 13, and the outer wall of the middle part of the air inlet pipe 14 is fixed with a ring edge 141, and the ring edge 141 is fixed on the top surface of the upper cover plate 12 Above, the top of the air inlet pipe 14 is connected with the air outlet pipe of the suction centrifugal fan 15, and the bottom end of the air inlet pipe 14 is screwed with a plug-in pipe 16, and the plug-in pipe 16 extends into the water liquid filled in the main barrel body 11;

[0019] The upper side wall of the main barrel body 11 is connected with an exhaust transverse pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com