Short-sizing billet discharge roller table balancing device of small billet

A technology of balancing device and billet, applied in the field of metallurgical equipment, can solve problems such as load eccentric load, and achieve the effects of improving service life, reducing load eccentric load and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

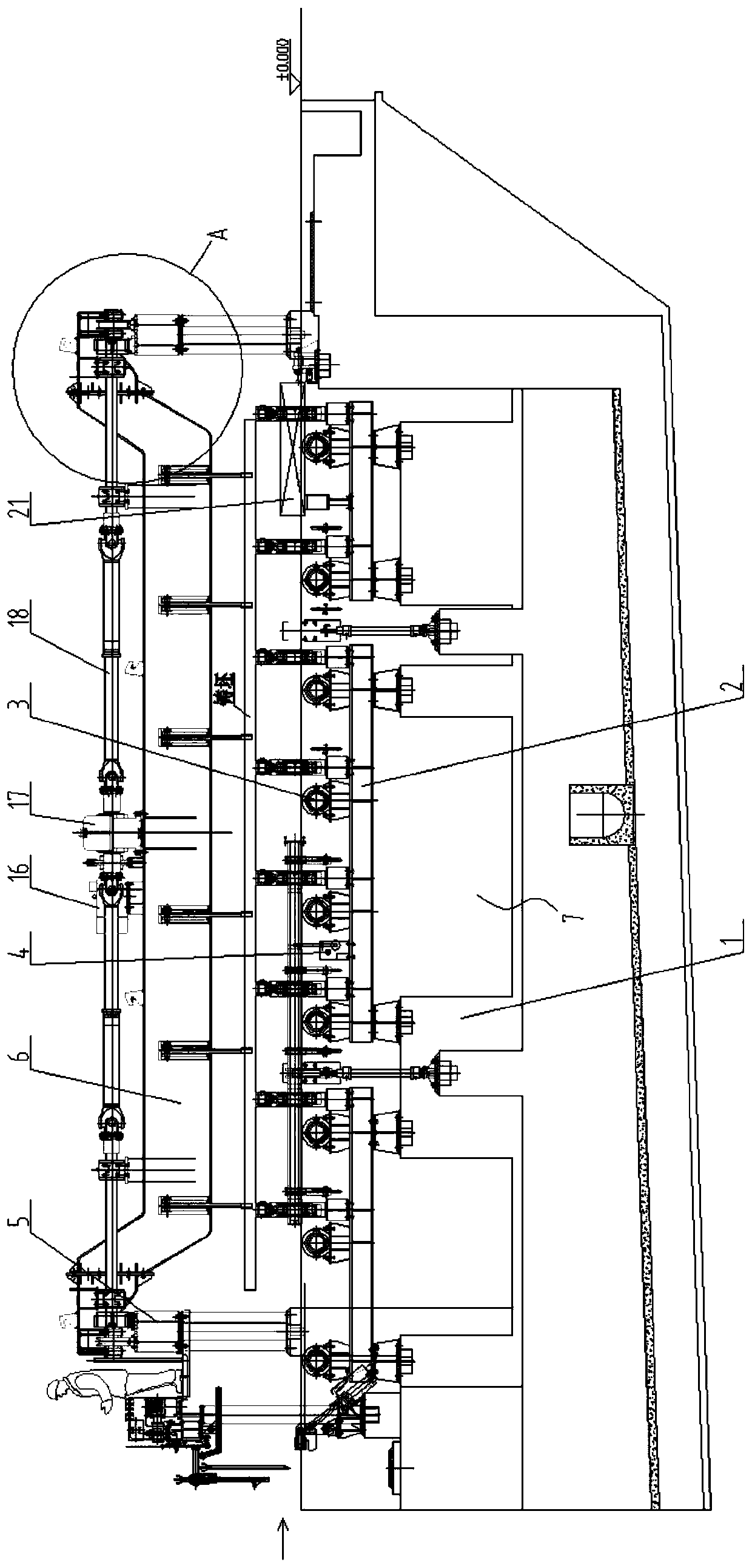

[0021] Specific implementation mode one: combine Figure 1-5 Describe this embodiment, the billet short-cut billet discharge roller table balancing device of this embodiment includes a base base 1, a roller table support beam 2, a roller table 3, a billet balancing device 4, a billet moving car track beam 5 and The billet moving car 6, the base base 1 is set in the ground pit 7, the base base 1 is equipped with a roller table support beam 2, and the roller table support beam 2 is equipped with a plurality of roller tables 3 arranged at intervals. The billet balancing device 4 is installed on the roller table support beam 2, the billet balancing device 4 is arranged between two adjacent roller tables 3, and the billet moving car track beam 5 is two parallel track beams , the track beam 5 of the billet moving car is arranged at the two ends of the roller table 3, the guide rail 8 is installed on the track beam 5 of the billet moving car, the two ends of the billet moving car 6 a...

specific Embodiment approach 2

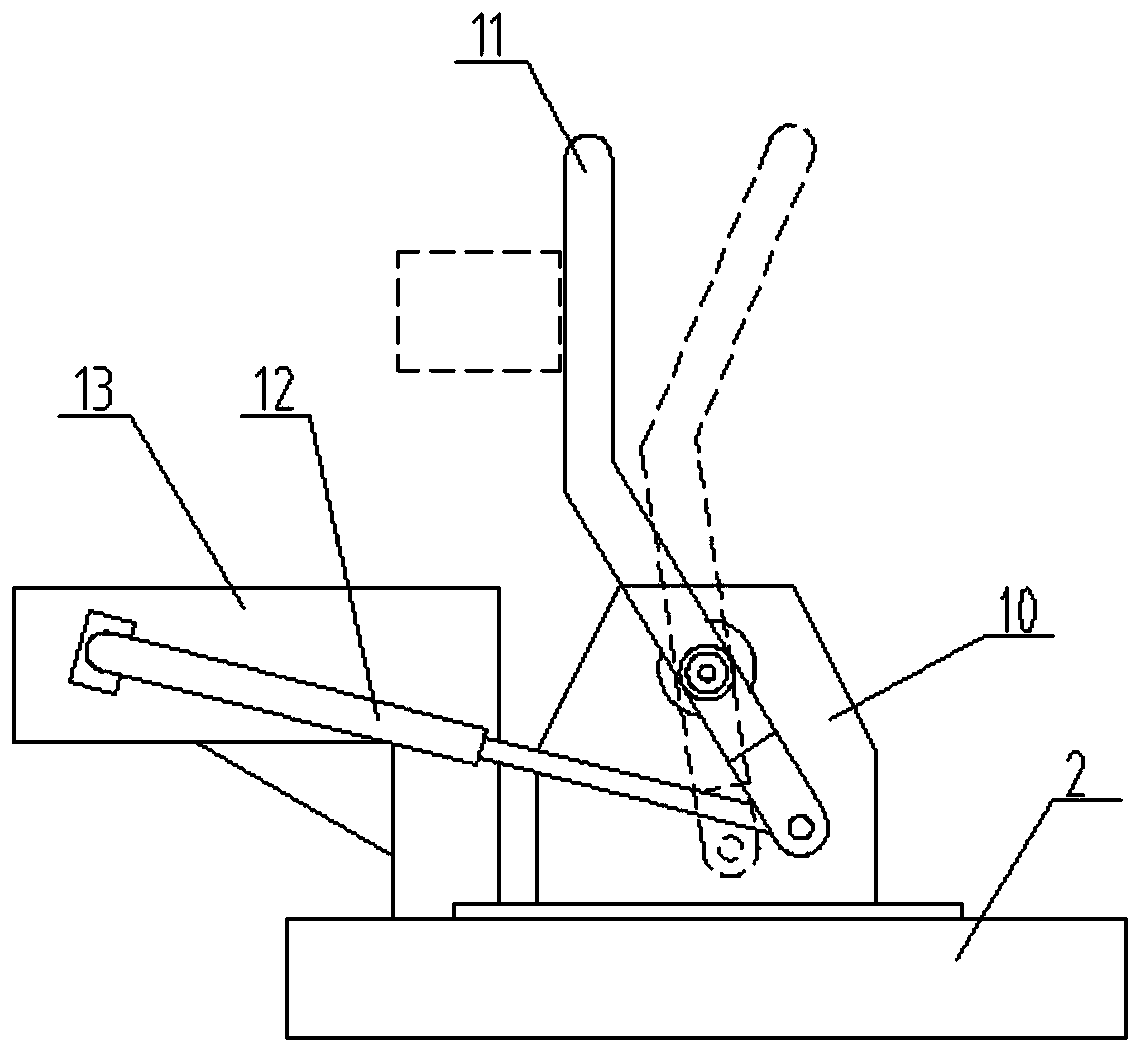

[0025] Specific implementation mode two: combination Figure 1-5 Describe this embodiment, the billet short-cut billet discharge roller table balancing device of this embodiment, the billet balancing device 4 includes a fixed seat 10, a push rod 11, a cylinder 12 and a cylinder support 13, the described The fixed seat 10 and the cylinder support 13 are fixedly installed on the roller table support beam 2, the push rod 11 is a bent push rod, the push rod 11 is installed on the fixed seat 10 in a rotating manner, and the cylinder support 13 is equipped with a cylinder 12 , the output end of the cylinder 12 and the bottom end of the push rod 11 are installed in cooperation. So set, the working process of the billet balancing device 4 is that the cylinder 12 acts to push the push rod 11 to rotate around the fixed seat 10. When the push rod 11 contacts the casting slab, the push rod 11 pushes the casting slab on the roller table 3, so that the casting The position of the slab on t...

specific Embodiment approach 3

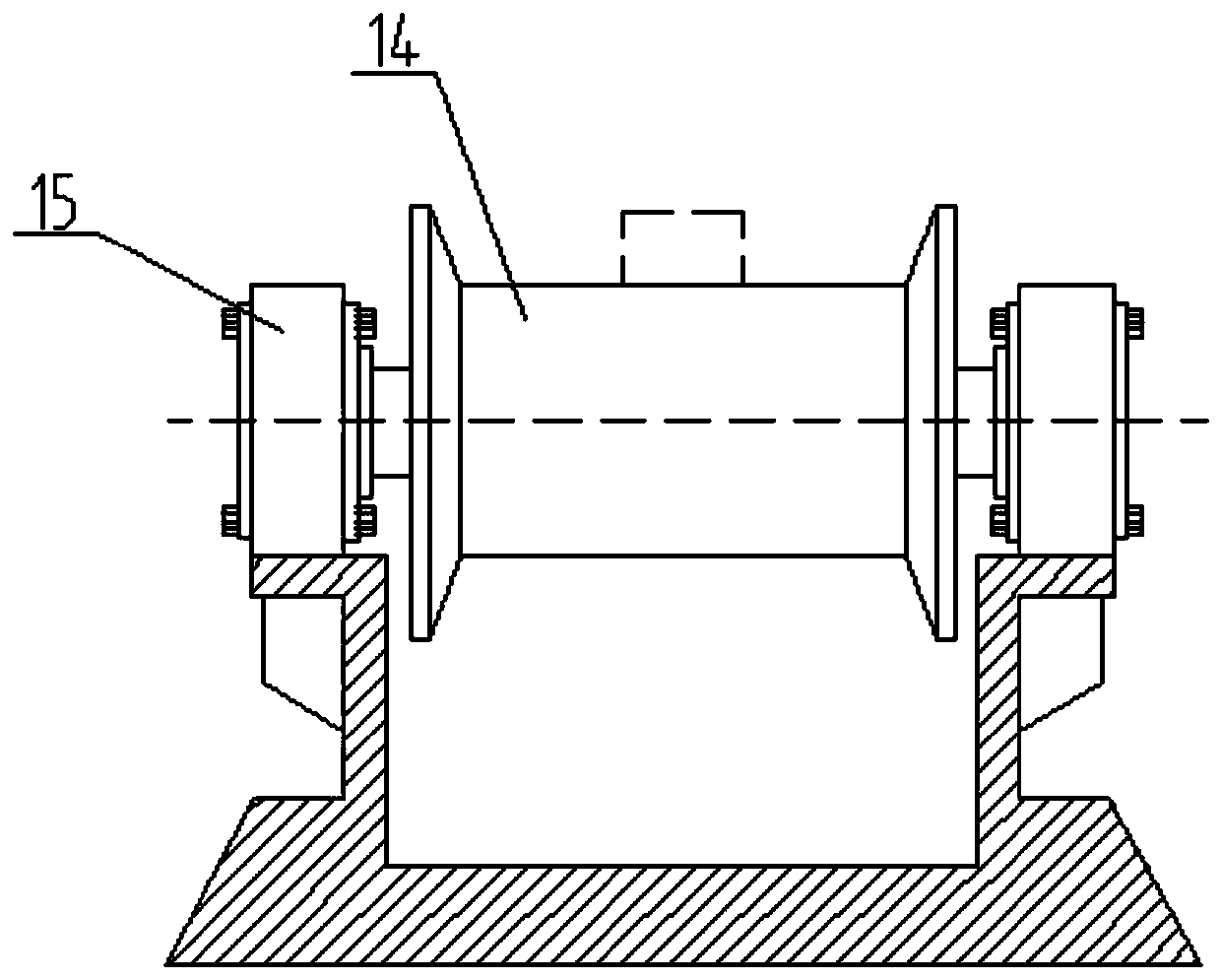

[0027] Specific implementation mode three: combination Figure 1-5 Describe this embodiment, the roller table balancing device for billet short-cut billet delivery in this embodiment, the roller table 3 includes a roller 14 and two bearing housings 15, and the bearing housings 15 are fixedly installed on the roller table supporting beam 2 , The roller 14 is installed in the bearing housing 15 through the bearing. In this way, the roller 14 is a circular roller, and the edge of the roller 14 has a surrounding edge, which is used to cover the casting slab and prevent the casting slab from slipping.

[0028] In order to adjust the installation height of the bearing seat 15, the bearing seat 15 can be installed on the roller table support beam 2 through a support.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap