A wire welding auxiliary tooling

An auxiliary tooling and wire technology, applied in auxiliary devices, welding equipment, connections, etc., can solve problems such as the impact of welding quality, and achieve the effects of stable and reliable operation, strong practicability, and improved versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

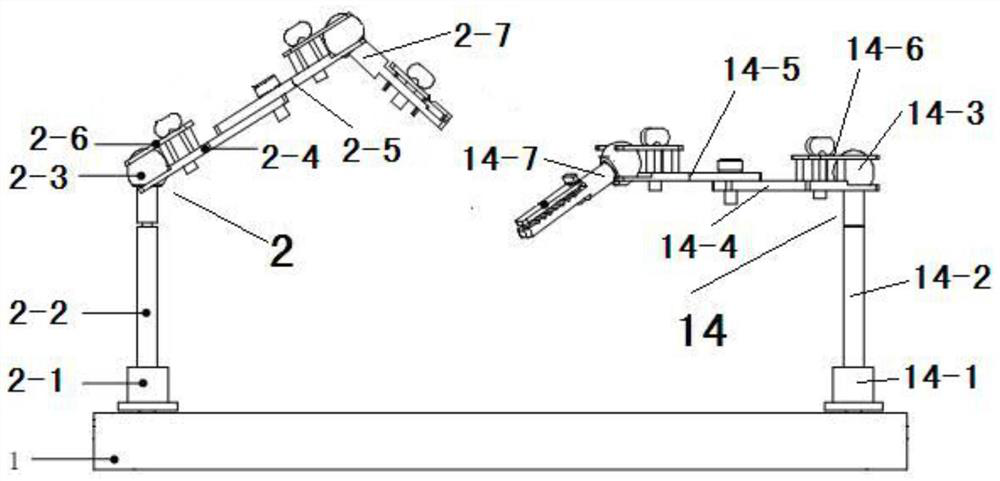

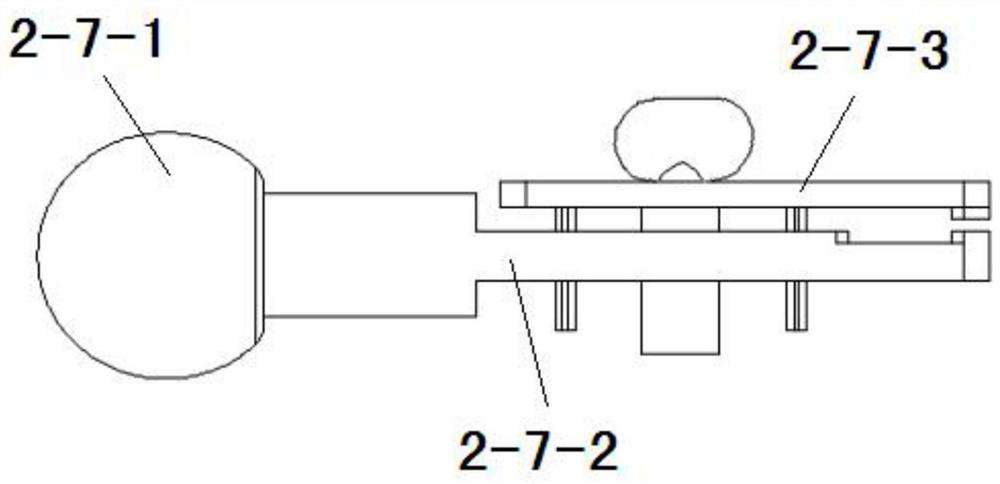

[0031] The invention provides a wire welding auxiliary tool, which is clamped by a base, a fastening screw sleeve, a support column, a universal ball connector, a connecting rod, a connecting rod pressing piece, a locking screw, a circuit board clamping device, and a wire clamping The cooperation of the device realizes the full contact between the wire and the solder hole of the circuit board or the tube leg of the device, and then holds the solder wire in one hand and the electric soldering iron in the other hand for one-time welding and forming. It makes up for the inconvenience of traditional electrical equipment, the need for secondary welding, black and non-wetting solder joints, and the use of prohibited and restricted processes.

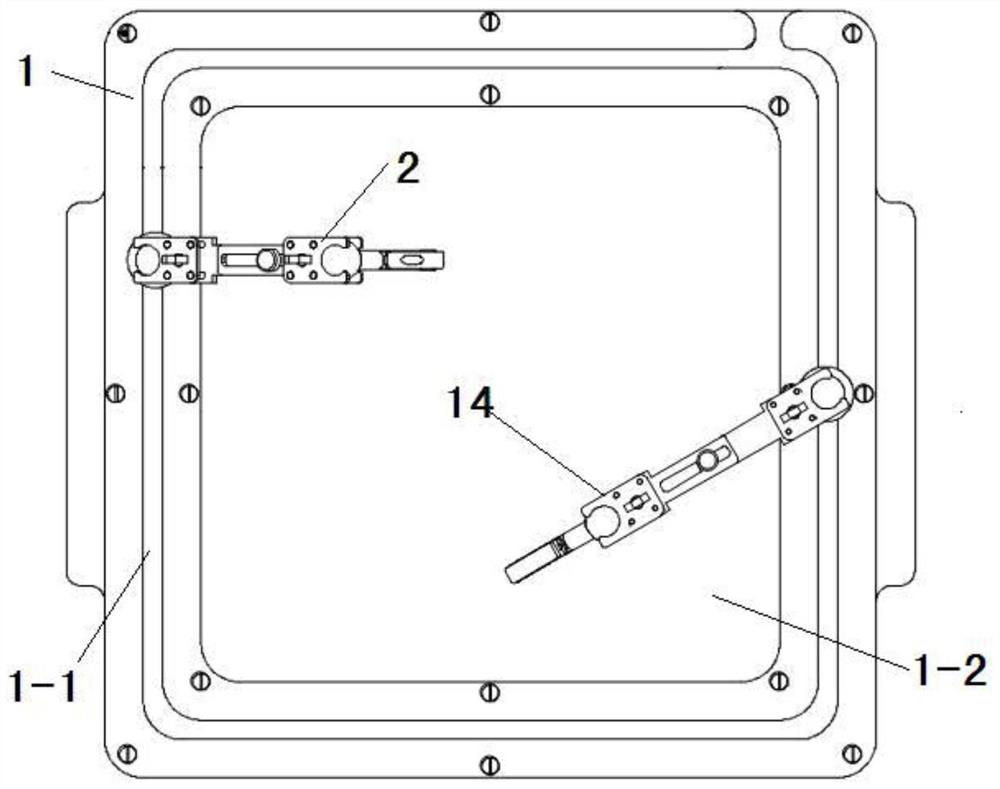

[0032] Such as figure 1 Shown is a top view of the welding auxiliary tool. It can be seen from the figure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com