Sluice chamber of sluice, sluice and assembly method of sluice chamber of sluice

An assembly method and technology of sluices, which are applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as long construction period, high cost of material purchase and transportation, and difficulty in controlling the quality of on-site construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

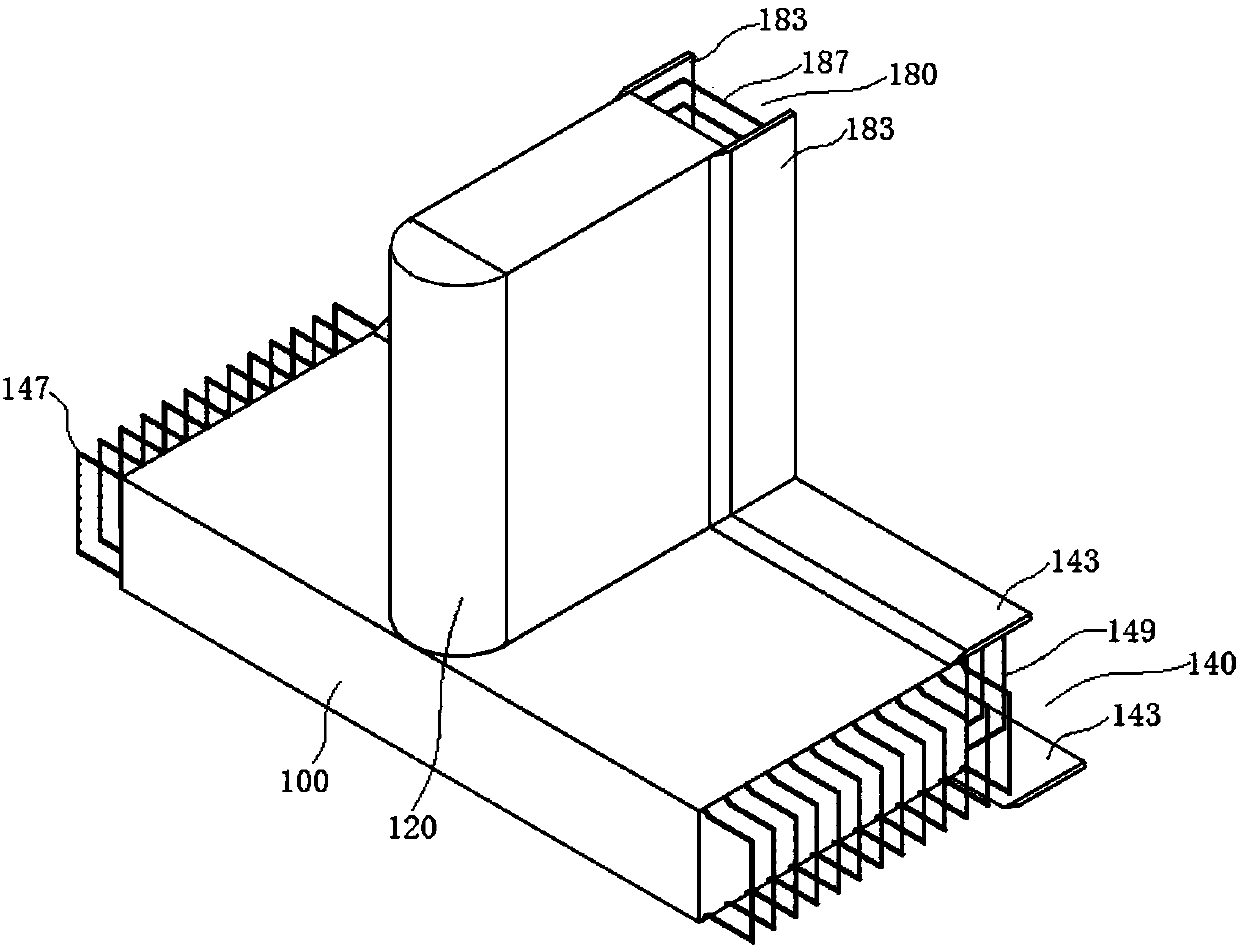

[0044] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left, right" usually refer to the orientations shown in the drawings and the orientations in practical applications, "inner, lower, left, right" "Outside" refers to the inside and outside of the outline of the part.

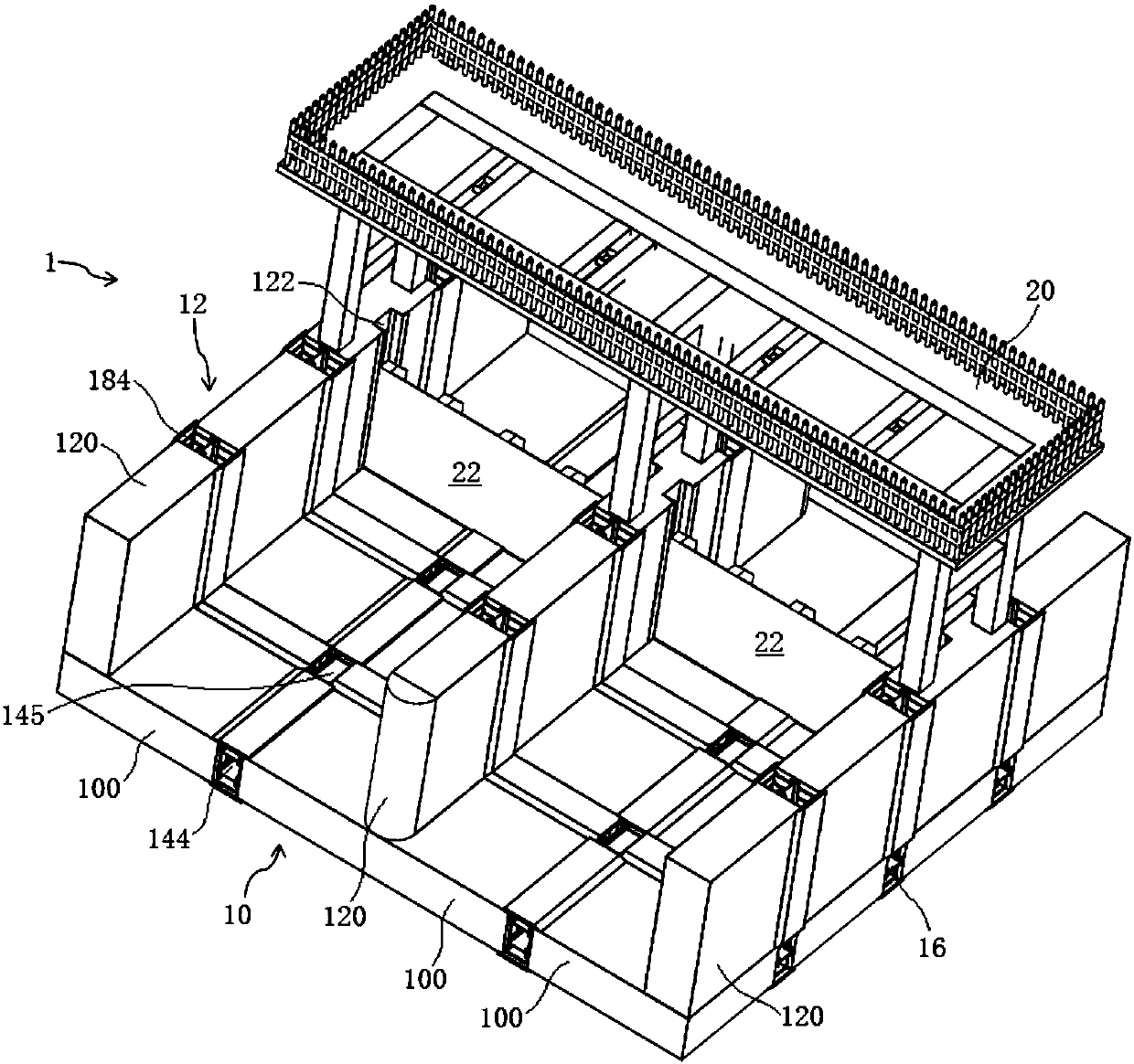

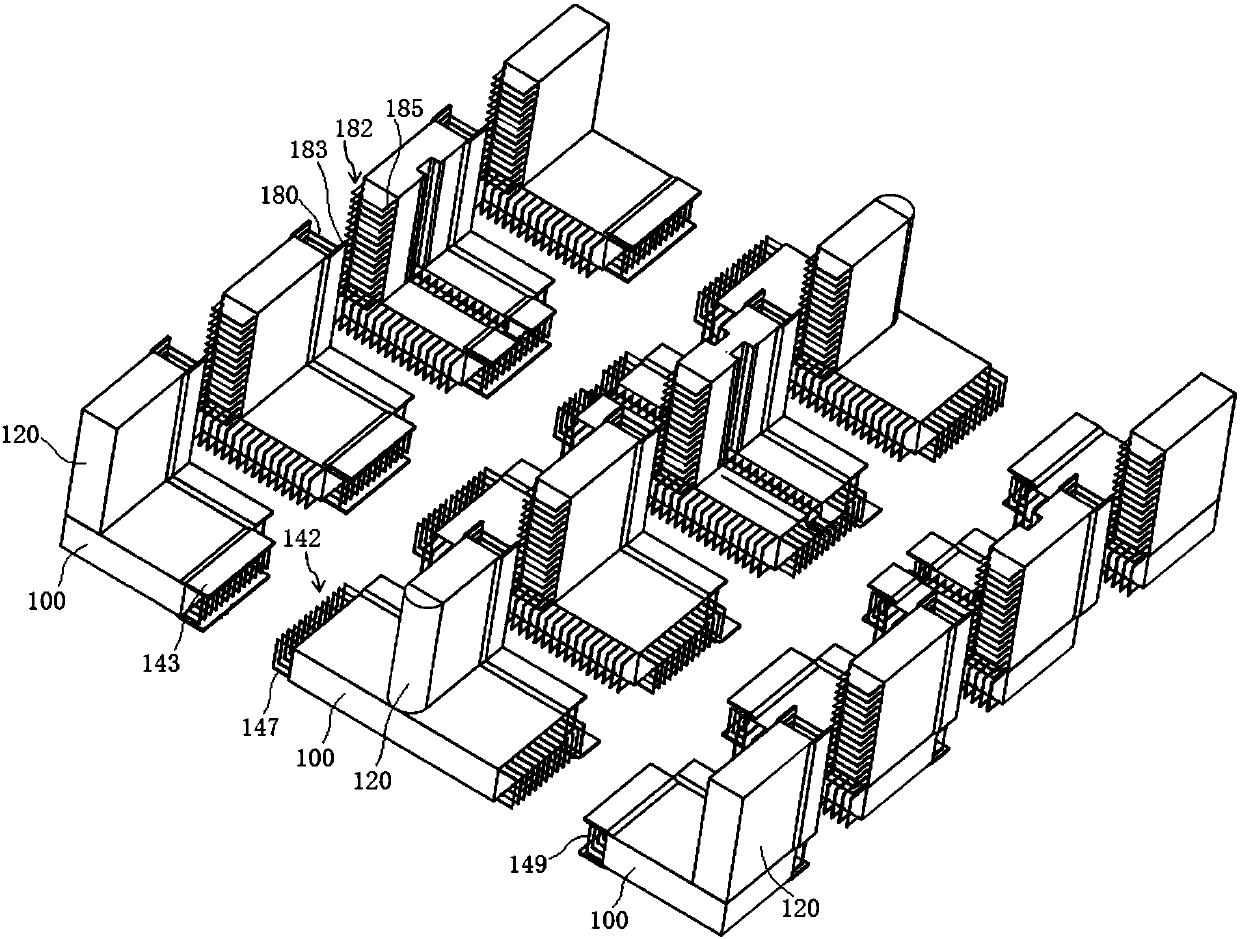

[0045] The present invention provides a sluice lock chamber. The sluice lock chamber 1 includes a prefabricated bottom plate 10 and a plurality of prefabricated side piers 12 supported on the prefabricated bottom plate 10, wherein two adjacent prefabricated side piers 12 are opposite and spaced apart so that The water flowing through the sluice chamber 1 passes through. By prefabricating the prefabricated bottom plate 10 and multiple prefabricated side piers 12 constituting the sluice lock chamber 1, and then assembling the prefabricated bottom plate 10 and multiple prefabricated side piers on site, the construction efficiency of the sluice lock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com