Multi-structure combined assembly pipe gallery with superposed member and construction method thereof

A technology of combined assembly and superimposed components, applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of complex structure and high waterproof performance requirements, save installation time, ensure pouring and maintenance quality, The effect of saving time in template setup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

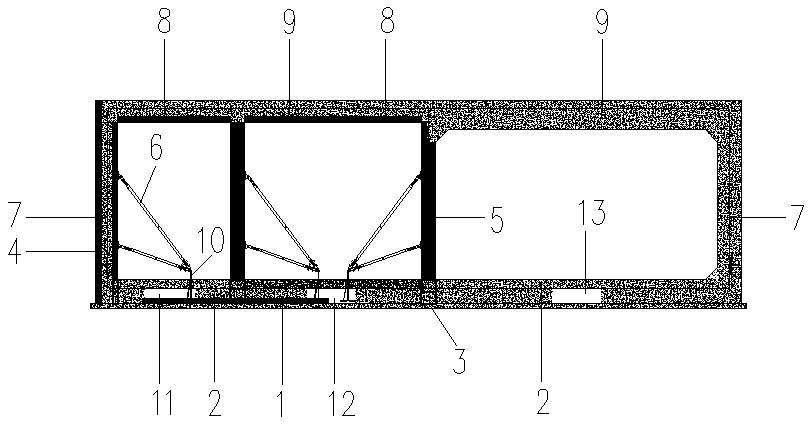

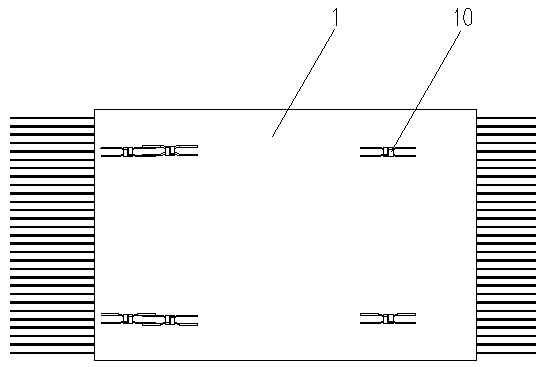

[0030] Such as figure 1 As shown in Fig. 1, a multi-structure combined assembled pipe gallery with superimposed components, including cast-in-place pipe gallery, prefabricated pipe gallery and semi-fabricated pipe gallery.

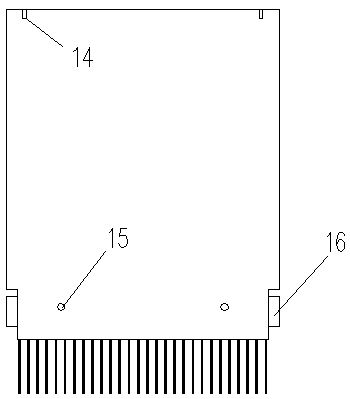

[0031] The prefabricated pipe gallery includes a solid prefabricated inner wall 5 arranged on the cast-in-place floor 2, the solid prefabricated inner wall 5 is arranged on both sides of the middle part of the cast-in-place floor 2, and the side of the solid prefabricated inner wall 5 is provided with diagonal braces 6, A prefabricated reinforced truss laminated roof 8 is installed between the tops of the solid prefabricated inner walls 5 on both sides, and the upper side of the prefabricated reinforced reinforced truss laminated roof 8 is a cast-in-place structural roof 9 .

[0032] The cast-in-place pipe gallery includes a cast-in-place outer wall 7 arranged on one side of the cast-in-place bottom plate 2 , and a cast-in-place structural roof 9 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com