Ceiling fan blade

A blade and ceiling fan technology, applied in the field of wind drive devices, can solve the problems of poor convenience and efficiency, inconvenient operation, time-consuming and inconvenient operation, and achieve the effect of improving operation convenience and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

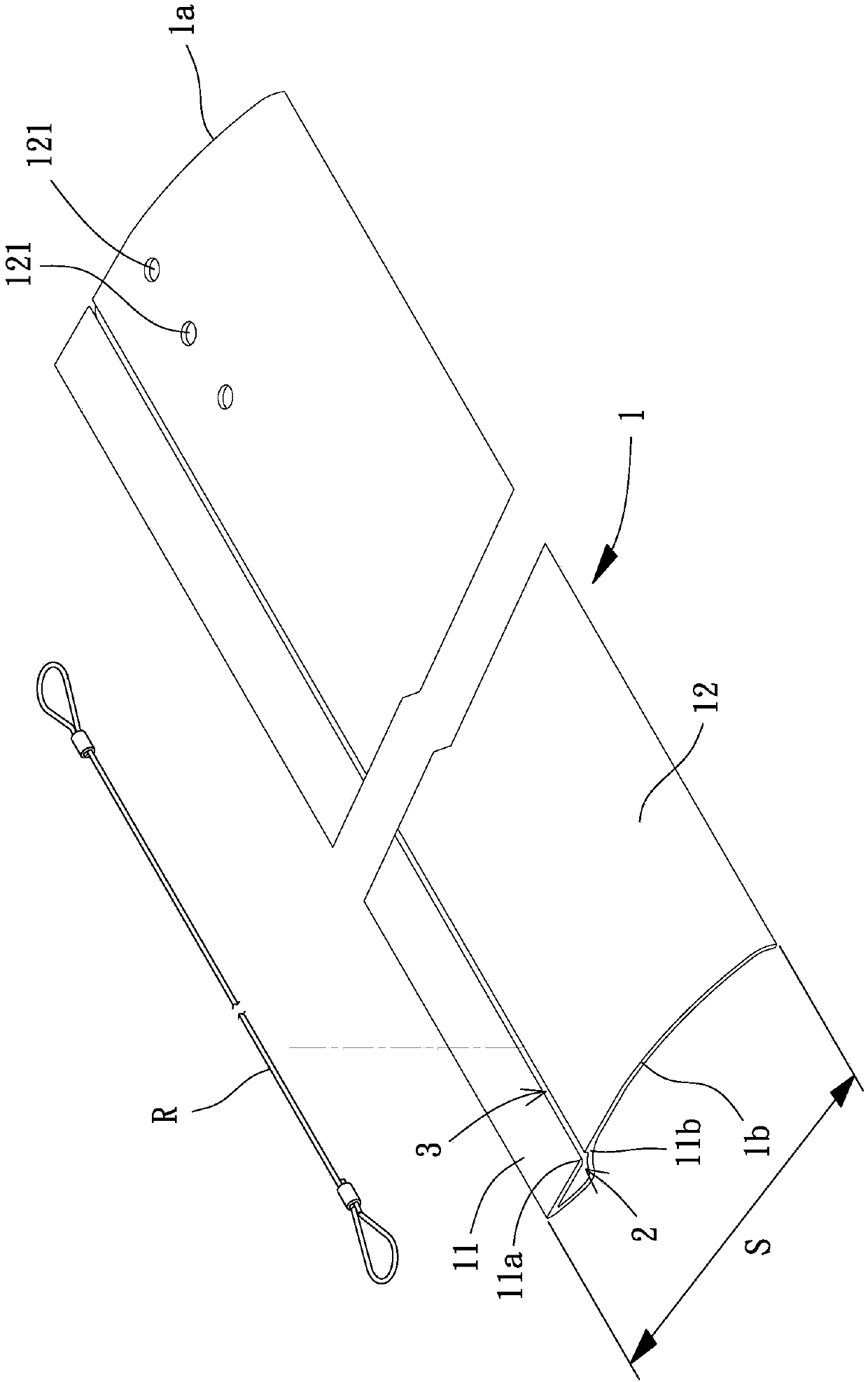

[0038] Please refer to figure 1 , the first embodiment of the ceiling fan blade of the present invention, the ceiling fan blade includes a blade body 1 , a channel 2 and a through groove 3 , the channel 2 is arranged on the blade body 1 , and the through groove 3 communicates with the channel 2 .

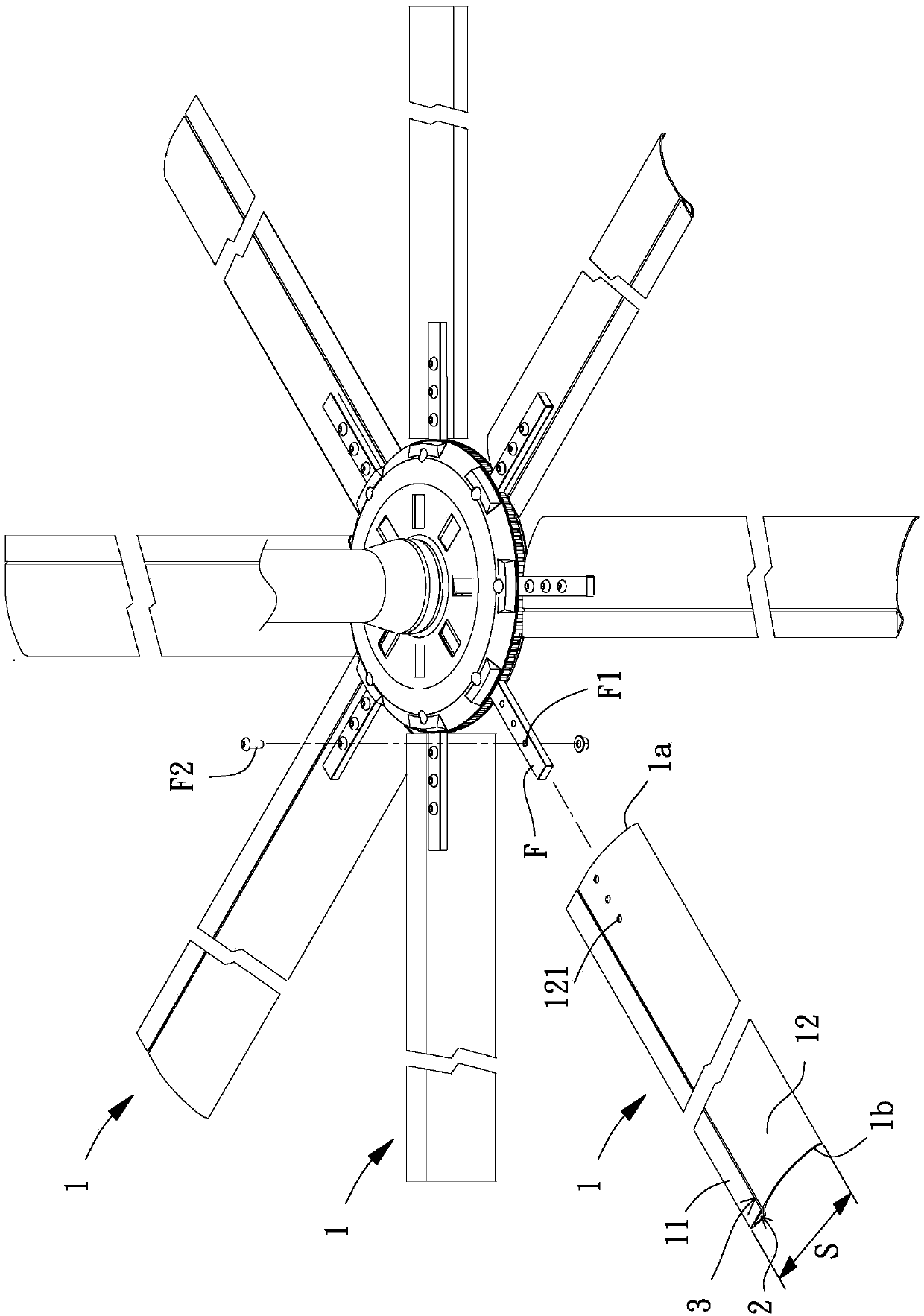

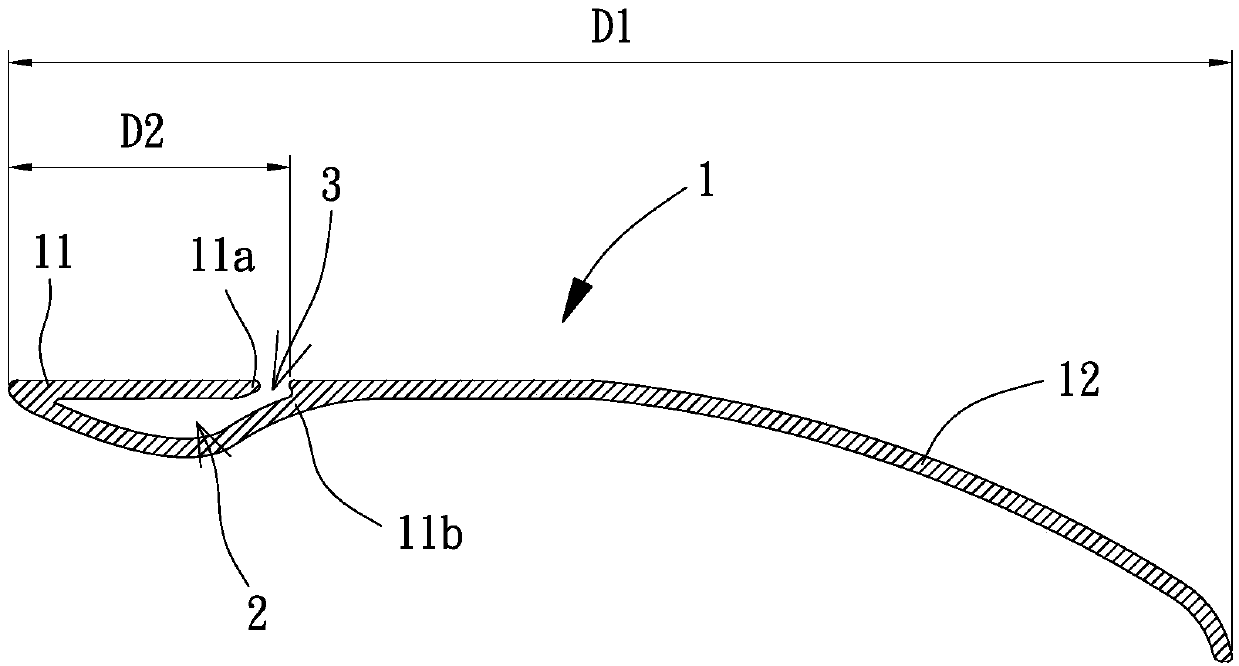

[0039] Please refer to figure 2 , 3 , the blade body 1 has a proximal end 1a and a distal end 1b opposite to each other, and the proximal end 1a can be combined with the locking bar F connected to the rotor. Specifically, the blade body 1 can be integrally formed by aluminum extrusion, and the blade body 1 can have a windward part 11 and a flow guide part 12 connected in the direction of the short side S; wherein, in the blade body 1 In the direction of the short side S, the blade body 1 has a first length D1, and the distance from the connection between the windward part 11 and the flow guide part 12 to the end of the windward part 11 away from the flow guide part 12 is a second...

no. 4 example

[0047] Please refer to Image 6 , the fourth embodiment of the ceiling fan blade of the present invention, the fourth embodiment of the present invention is substantially the same as the above-mentioned third embodiment, the main difference is that: the fourth embodiment of the present invention can also include at least one reinforcing rib 4 The at least one reinforcing rib 4 is connected to the opposite inner wall surface of the windward part 11, so that the at least one reinforcing rib 4 can be located in the channel 2; thereby, the structural strength of the windward part 11 can be further improved.

[0048] To sum up, the ceiling fan blade of the present invention uses the channel to extend from the proximal end to the distal end, and the groove communicates with the channel; when the safety cable is to be assembled on the ceiling fan blade, the groove can be used for The safety wire extends laterally, so that the safety wire can be directly inserted into the passage thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com