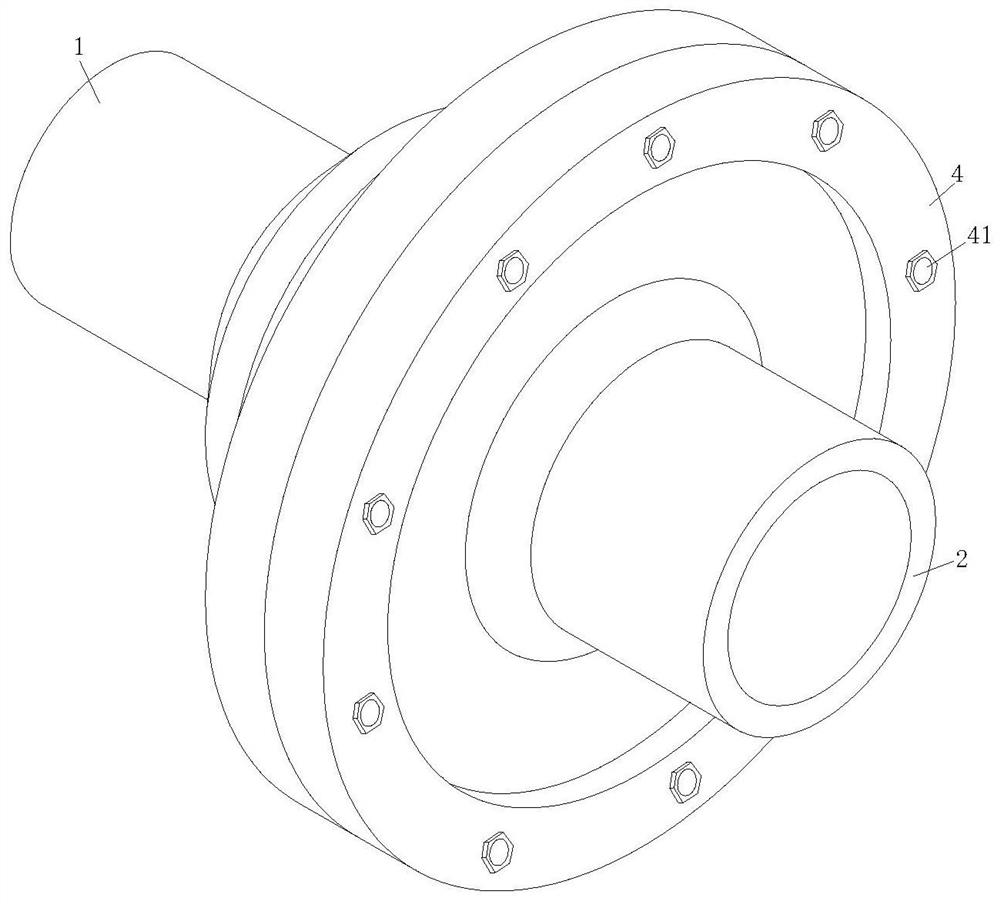

a compensator

A compensator, No. 1 technology, applied in the field of compensators, can solve the problems of easy loss of sealing packing, gas leakage, affecting the overall sealing performance of the compensator, etc., and achieve the effects of improving service life, increasing resistance, and improving initial sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

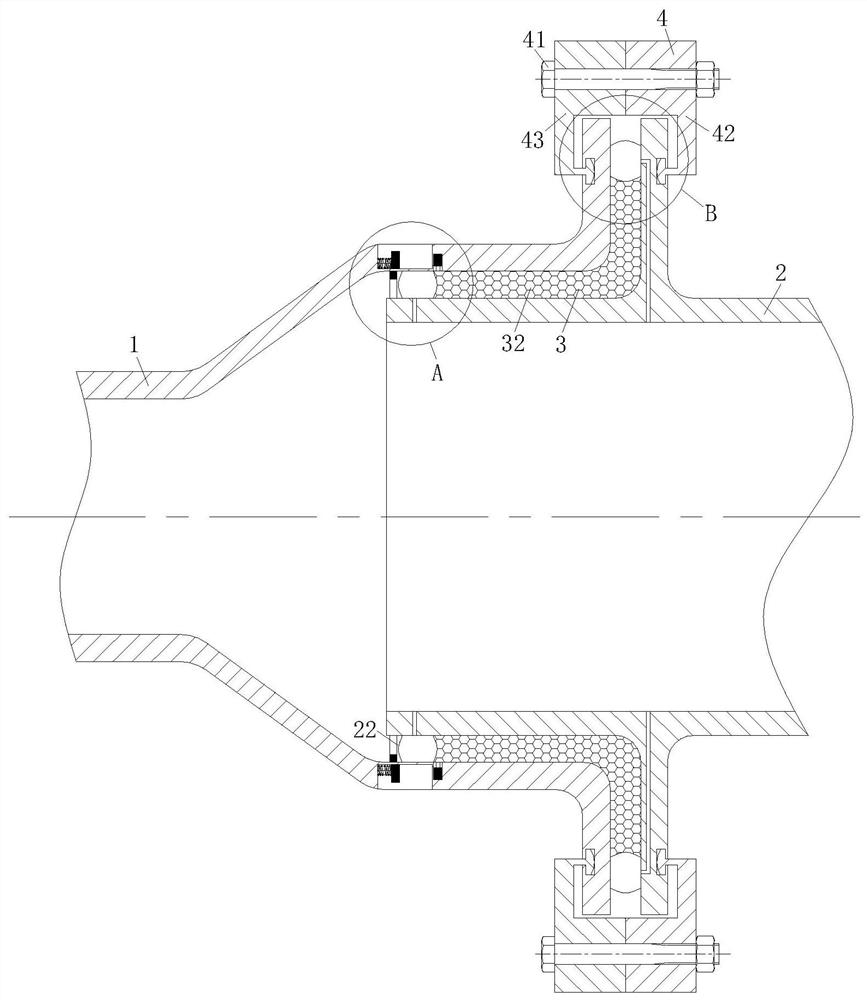

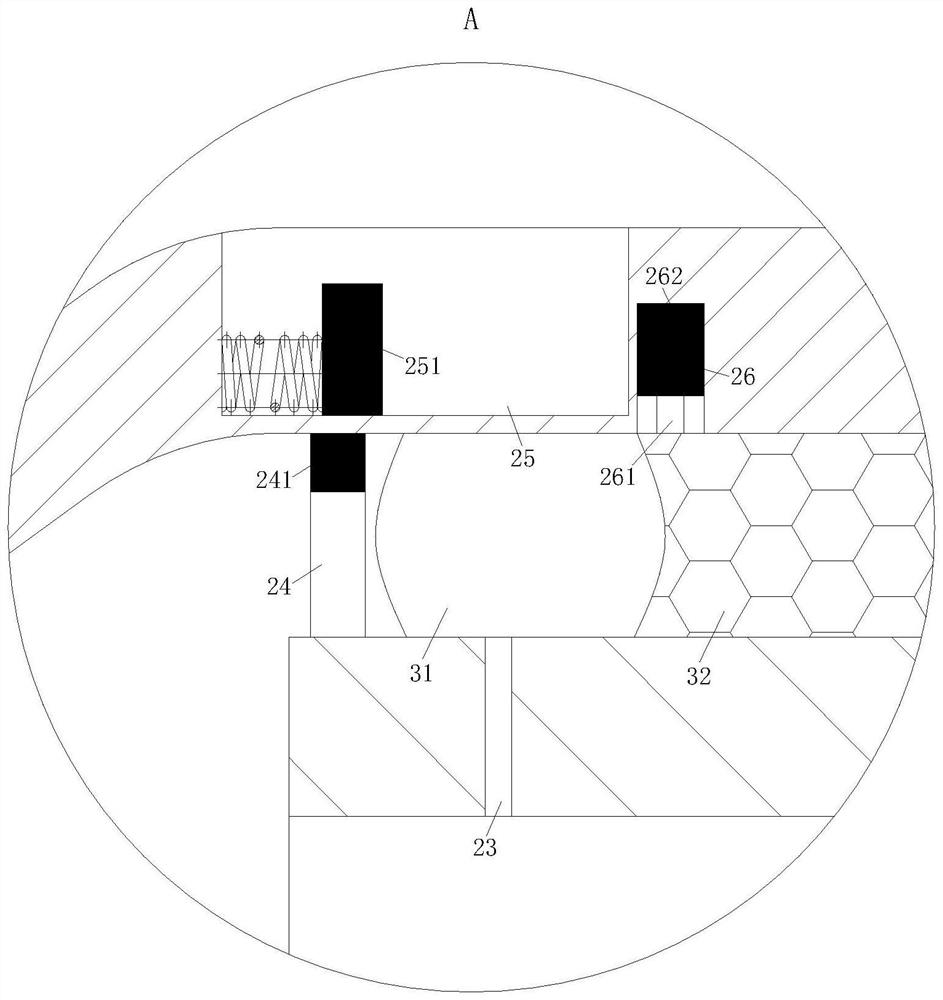

[0023] As an embodiment of the present invention, the end of the elastic sheet 24 is provided with a No. 1 magnet 241; the side wall of the outer cylinder 1 is provided with a cavity 25 near the No. 1 magnet 241; the cavity 25 is provided with a No. 2 magnet Magnet 251; through the cooperation of No. 1 magnet 241 and No. 2 magnet 251, the buffer time for inflating the airbag 31 is increased; when working, when the gas passes through the compensator, the gas enters the airbag 31 through the vent hole 23, and the gas with a certain pressure enters the airbag 31, the airbag 31 is fully inflated, so as to realize the sealing between the inner tube 2 and the outer tube 1 and between the gap 22 and the inside of the compensator; in the process of gas entering the airbag 31, considering that the inflation speed of the airbag 31 is slow, Therefore, there is a spring sheet 24 on the outer side wall of the end of the inner cylinder 2 close to the airbag 31, which can give the airbag 31 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com