Method and system for matching air supply volume and exhaust air volume under variable air volume conditions

A technology of air supply and variable air volume, which is applied in the field of systems where the air supply volume of the air supply center in the factory area is matched with the variable air volume of the exhaust air. The pressure gradient increases and other problems, so as to achieve the effect of matching and stable air supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for matching the air volume of the air supply center in the plant area with the variable air volume of the exhaust air, which is specifically used for the ventilation treatment of the entire plant of the spent fuel reprocessing plant.

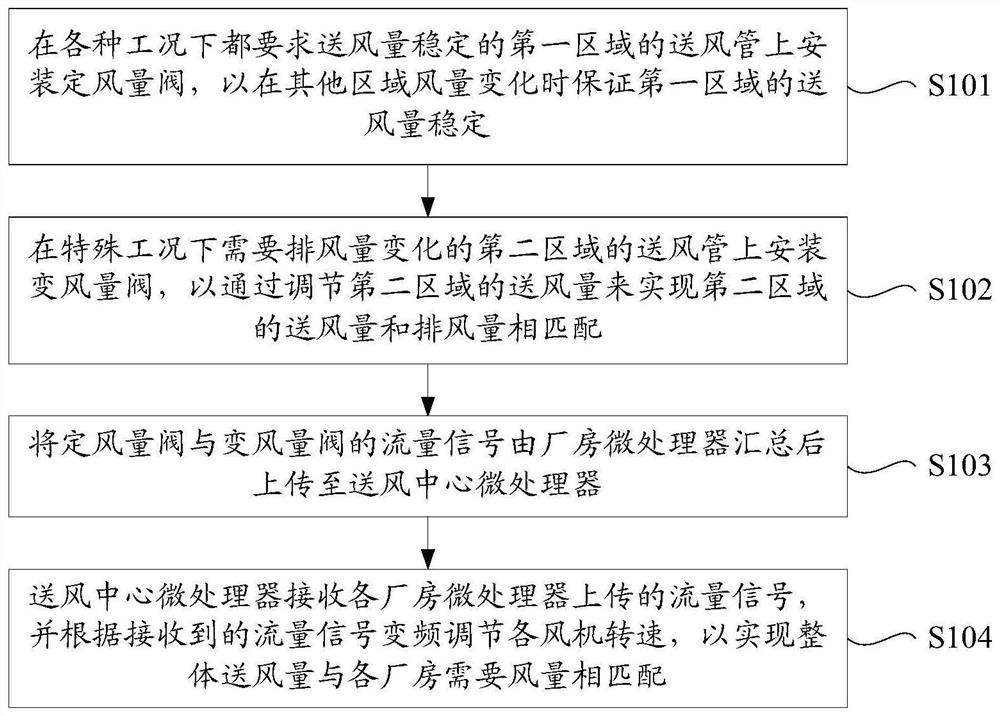

[0039] like figure 1 As shown, the method includes the following steps S101 and S102.

[0040] S101. A constant air volume valve is installed on the air supply pipe of the first area that requires a stable air supply volume under various working conditions, so as to ensure the stability of the air supply volume in the first area when the air volume in other areas changes;

[0041] S102. Install a variable air volume valve on the air supply pipe of the second area that needs to change the exhaust air volume under special working conditions, so as to achieve the same air supply volume and exhaust air volume in the second area by adjusting the air supply volume of the second area. match. Among them, the s...

Embodiment 2

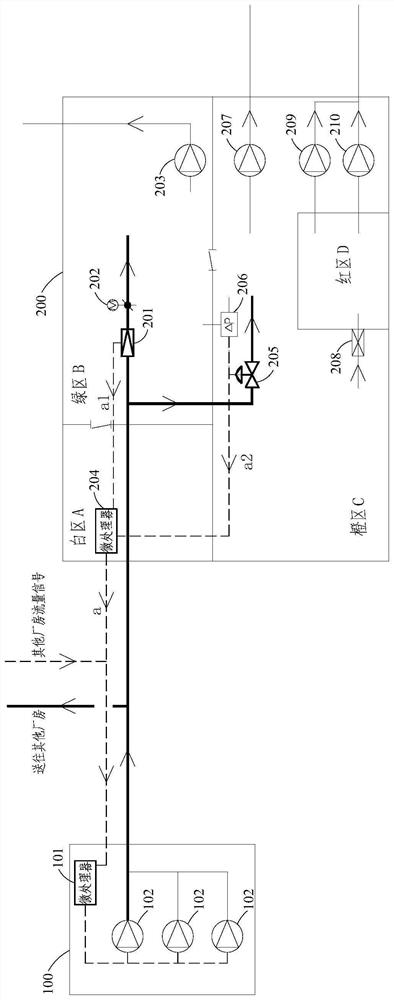

[0058] This embodiment provides a system that realizes the matching of the air supply volume of the air supply center in the plant area and the variable air volume of the exhaust air, which is specifically used for the ventilation treatment of the entire plant of the spent fuel reprocessing plant.

[0059] like figure 2 As shown, the system includes: a constant air volume valve 201 and a variable air volume valve 205 .

[0060] The constant air volume valve 201 is installed on the air supply pipe of the first area that requires stable air volume under various working conditions, and is used to ensure the stability of the air volume in the first area when the air volume in other areas changes; the variable air volume valve 205 is installed On the air supply duct of the second area where the exhaust air volume needs to be changed under special working conditions, it is used to match the air supply volume and exhaust air volume of the second area by adjusting the air supply volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com