Cyclone scrubber

A cyclone washing and cyclone technology, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of cumbersome waste disposal, fast adsorption efficiency decline, and complicated adsorption process, so as to avoid rapid adsorption capacity. Decrease, low operating cost, and stable air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

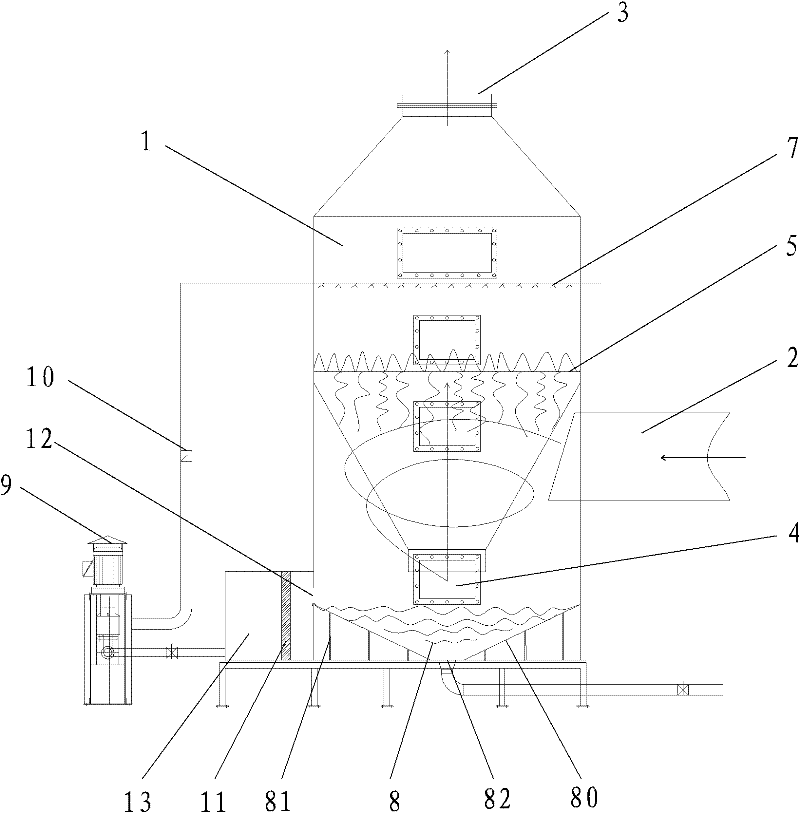

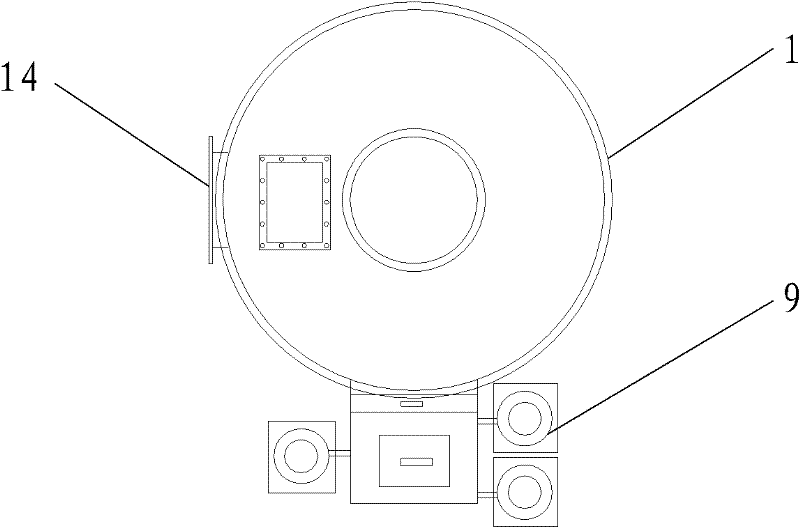

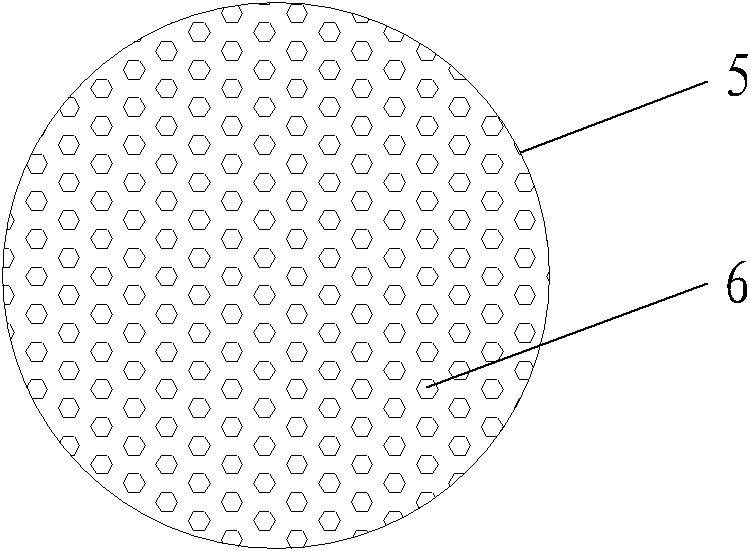

[0023] As shown in the figure, a cyclone washing tower has a tower body 1, and a waste gas inlet 2 and a clean gas outlet 3 are opened on the tower body 1. Inside the tower body 1, a cyclone area and a spray area are arranged on the upper part of the cyclone area. The intake direction of the exhaust gas inlet 2 is perpendicular to the axis line where the tower body 1 is located, and the gas outlet direction of the clean gas outlet 3 is consistent with the axis line where the tower body 1 is located. Among them: the cyclone area is provided with a cyclone generator 4; the spray area is provided with a sieve layer 5 with several sieve holes 6 and a spraying system which is arranged on the upper part of the sieve layer 5 and consists of a plurality of spray heads 7. device.

[0024] The bottom of the tower body 1 is provided with a liquid storage tank 8, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com