Battery data routing inspection instrument with variable routing inspection cycle and routing inspection method

A technology of inspection cycle and battery data, applied in the direction of instruments, measurement of electricity, measurement of electric variables, etc., can solve the problems of huge amount of communication data and repeated data, unable to truly reflect the system status, and the inspection cycle is set too long. Saving communication expenses, optimizing communication expenses, high promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

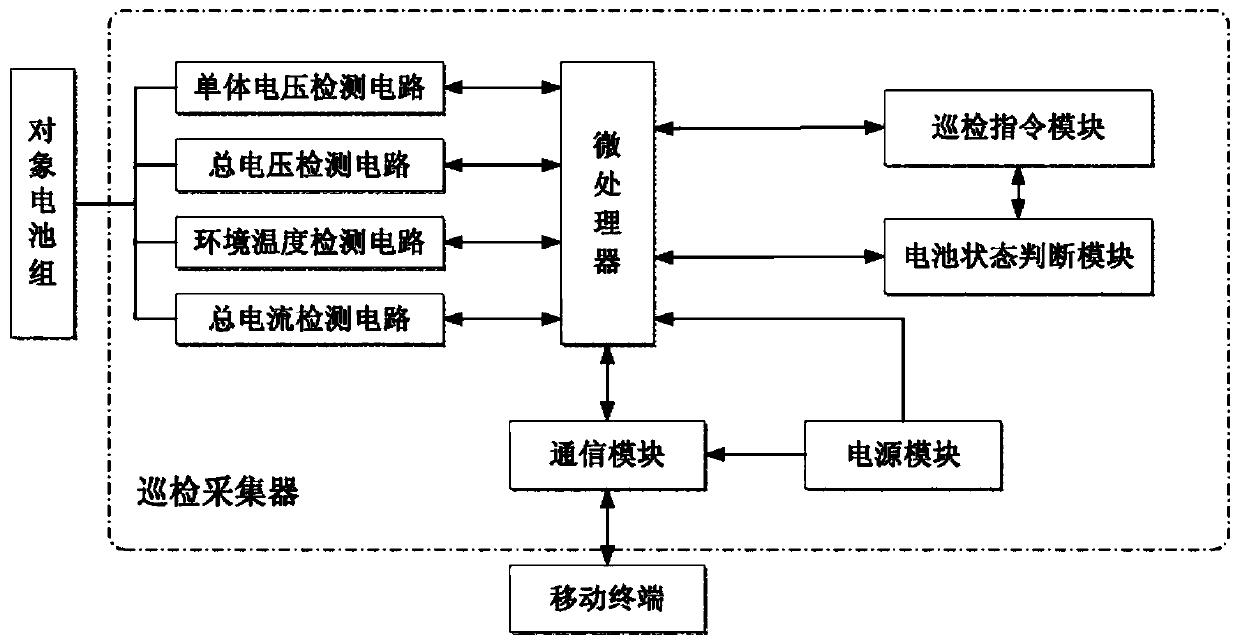

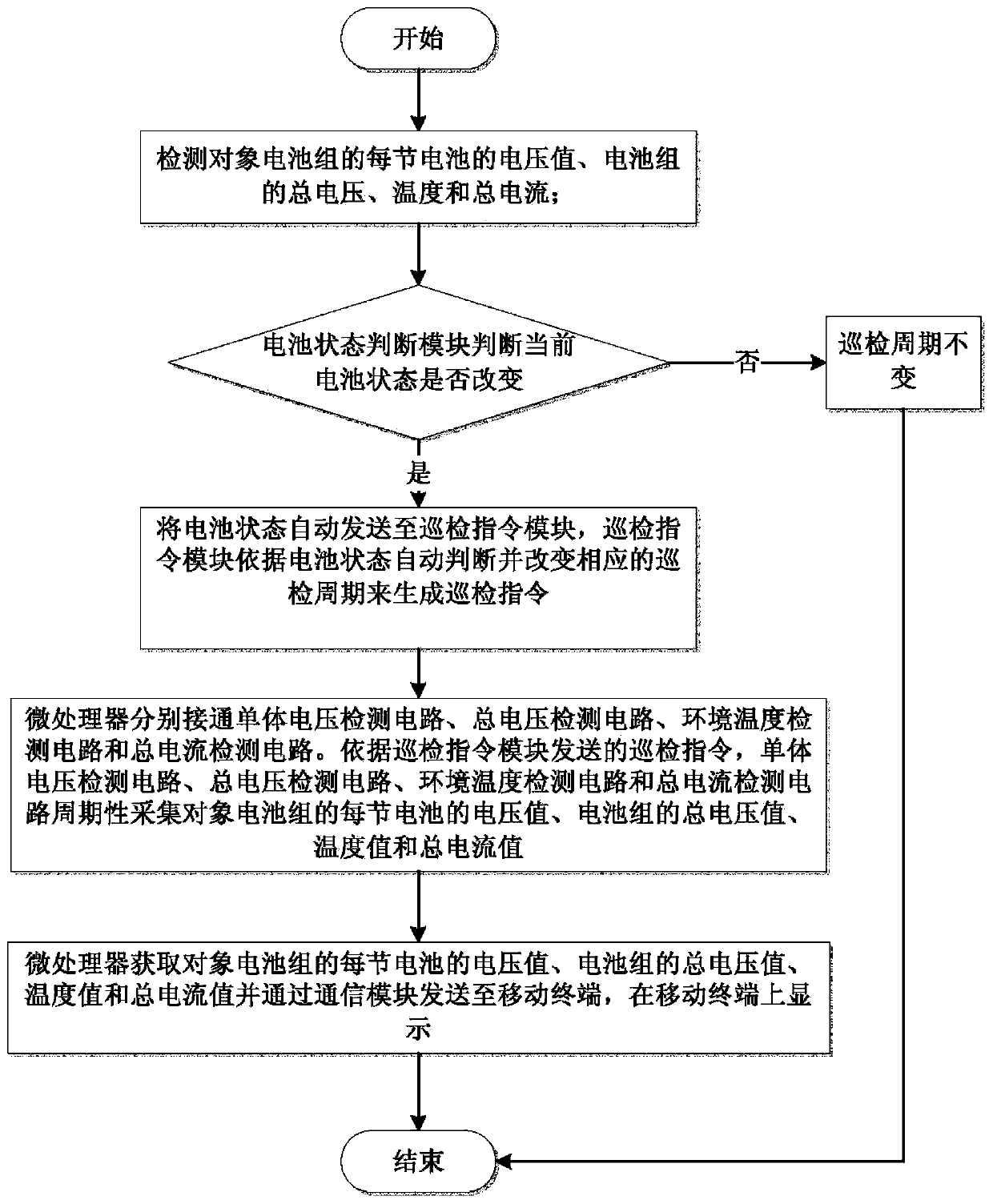

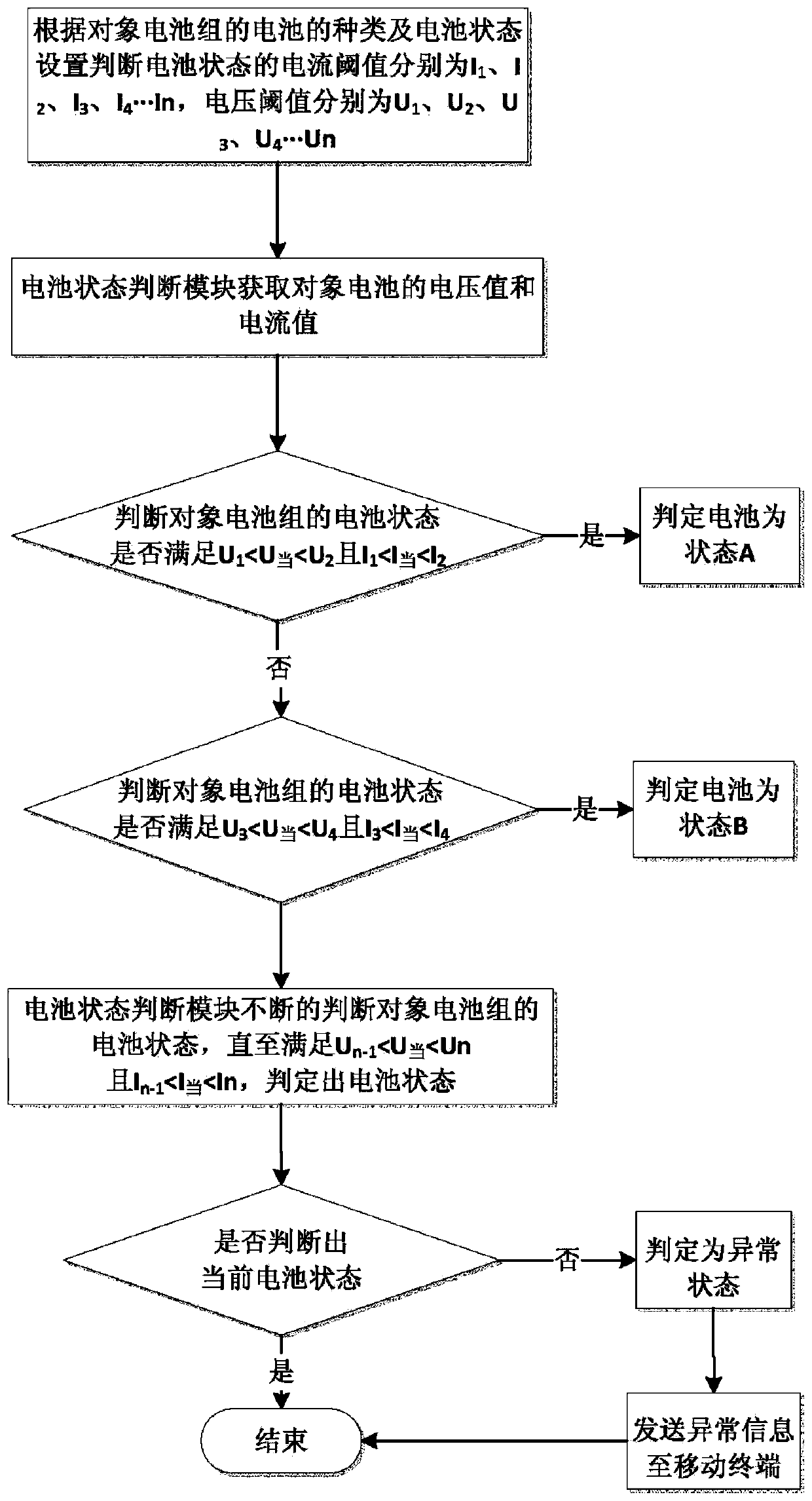

[0024] Such as figure 1 The structure connection block diagram of the battery data inspection instrument with variable inspection period is shown. The battery data inspection instrument with variable inspection period includes the target battery pack, inspection collector and mobile terminal. The inspection collector includes a single voltage Detection circuit, total voltage detection circuit, ambient temperature detection circuit, total current detection circuit, microprocessor, battery status judgment module, inspection command module, communication module and power supply module, single voltage detection circuit detection object battery pack The voltage of the battery, the total voltage detection circuit detects the total voltage of the target battery pack, the ambient temperature detection circuit detects the temperature in the target battery pack, the total current detection circuit detects the total current of each battery pack, the single voltage detection circuit, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com