Electronic paste manufacturing equipment and manufacturing method

A technology for electronic paste and manufacturing equipment, which is used in cable/conductor manufacturing, heat treatment equipment, chemical instruments and methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

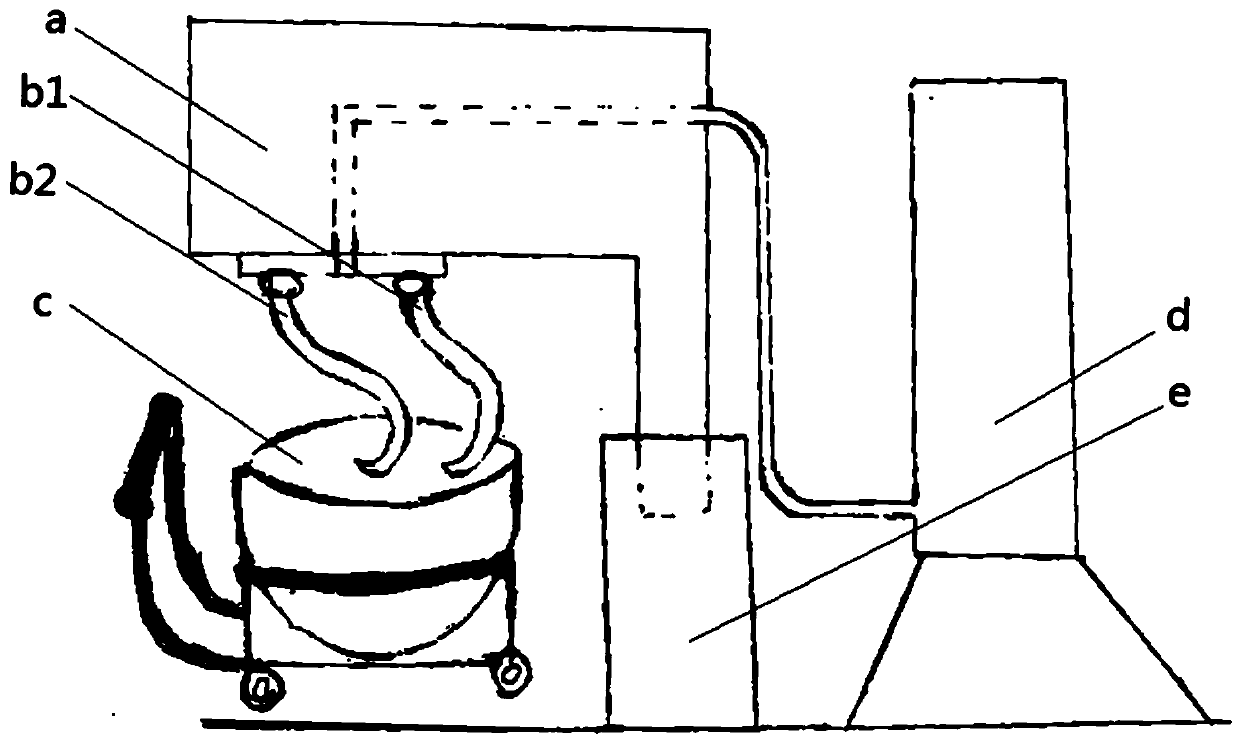

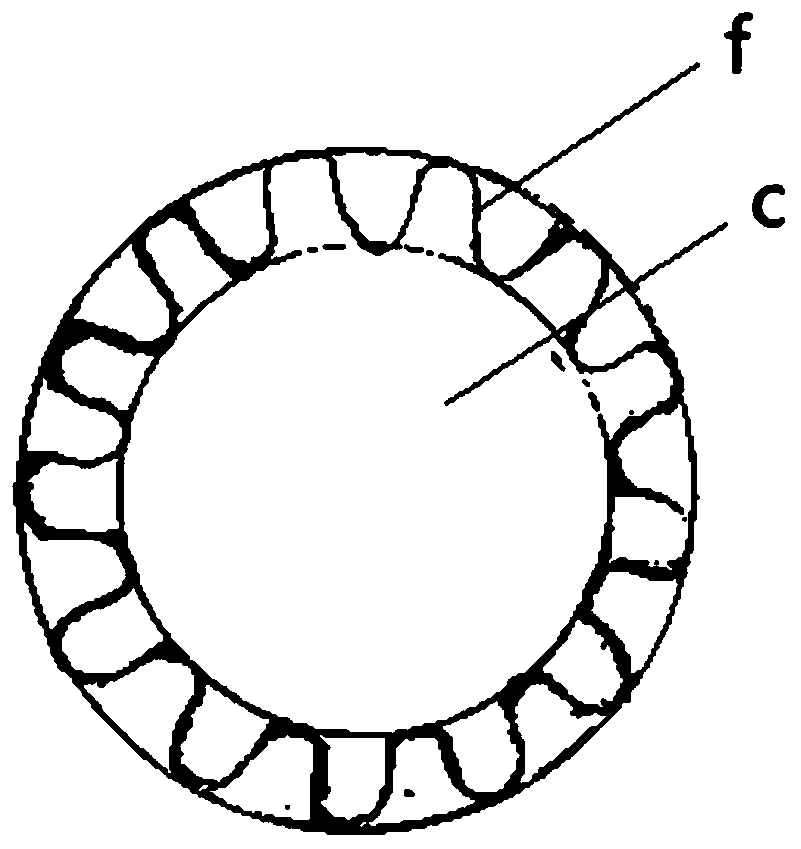

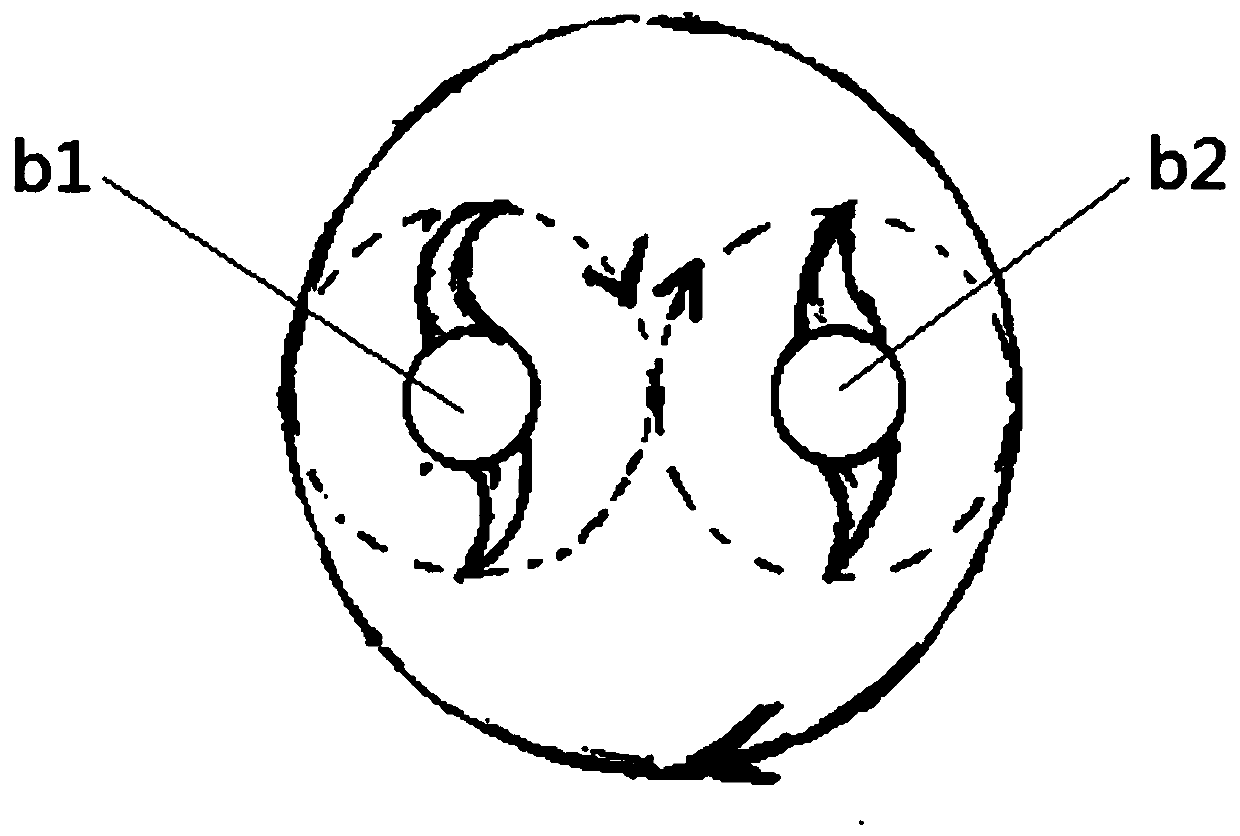

[0033] Manufacture of electronic paste

[0034] Conventional electronic slurry manufacturing needs to go through six processes: batching-room temperature placement-stirring-rolling-vacuum sieving-vacuum stirring. Taking the production of 100KG slurry as an example, the time taken by each process is 1h-12h-1h-12h- 1h-1h, the total time spent is 28h. Because no manual operation is required during normal temperature storage, except for this part, the entire slurry manufacturing process requires 16 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com