Plug structure and handle containing plug structure

A plugging and handle technology, applied in medical science, dentistry, dental drilling, etc., can solve problems such as stuck, poor comfort, and reduced power of the handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

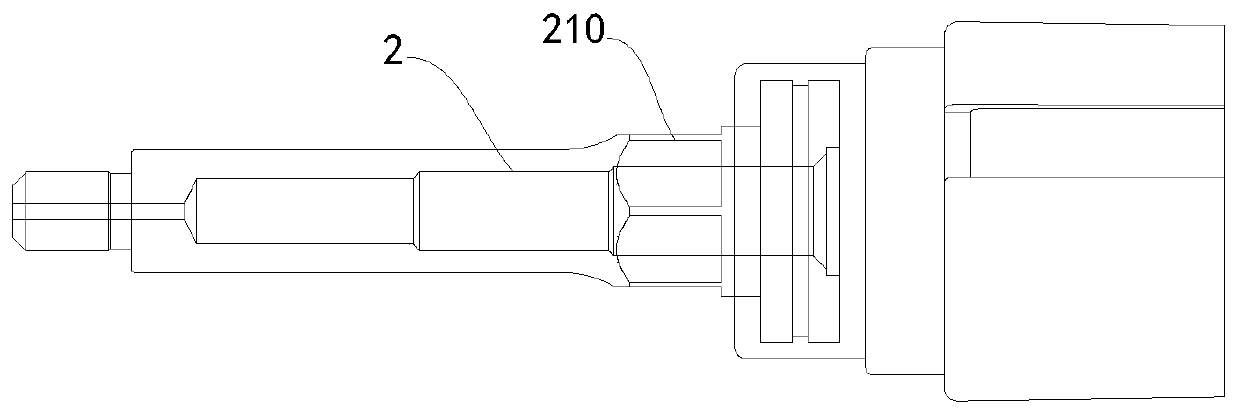

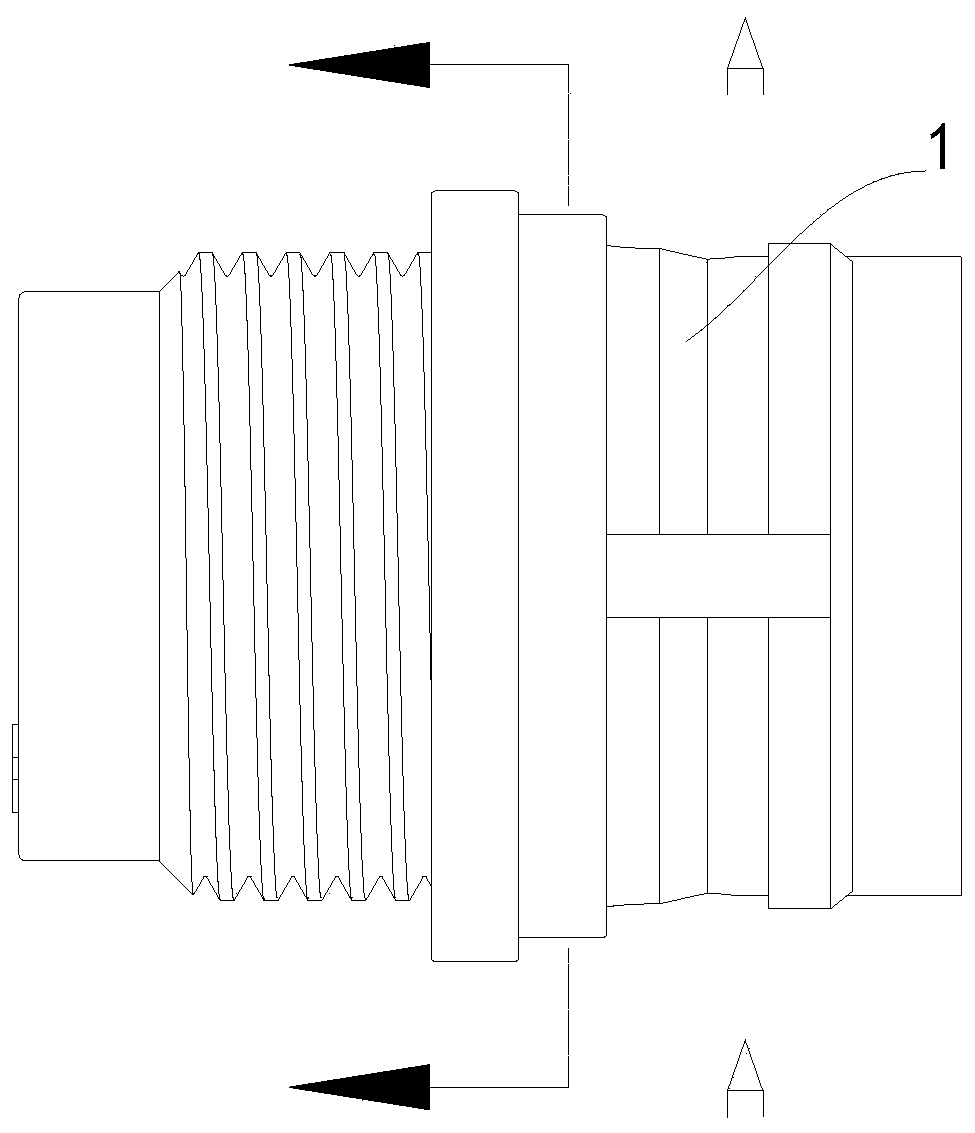

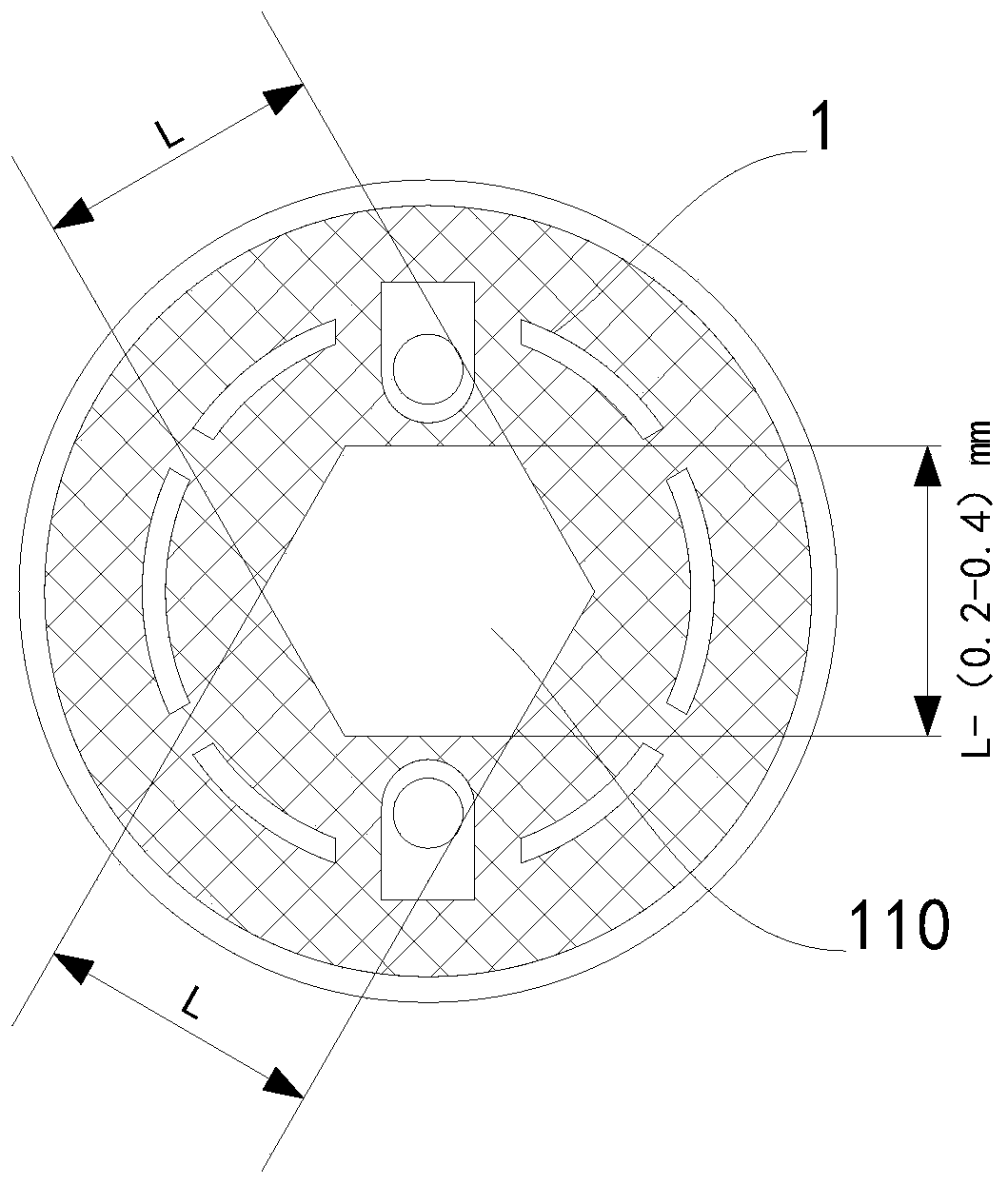

[0027] Such as figure 1 , figure 2 , image 3 As shown, a plug structure includes a plug 1 and a horn 2, and the horn 2 has an outer hexagonal cylinder 210, that is, the radial cross-sectional shape of the outer hexagonal cylinder 210 is a regular hexagon, and the plug 1 is provided with an inner hexagonal hole 110 matched with the outer hexagonal cylinder 210, and the outer hexagonal cylinder 210 is penetrated in the inner hexagonal hole 110, through the outer hexagonal cylinder 210 of the horn 2 and the inner hexagonal hole of the plug 1 The holes 110 cooperate with each other to realize torque transmission. In the prior art, the radial cross-sectional shape of the inner hexagonal hole 110 on the plug 1 is a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com