Overturning support welding jig

A technology of flipping brackets and welding fixtures, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of simple operation, good adjustment ability, and convenient welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

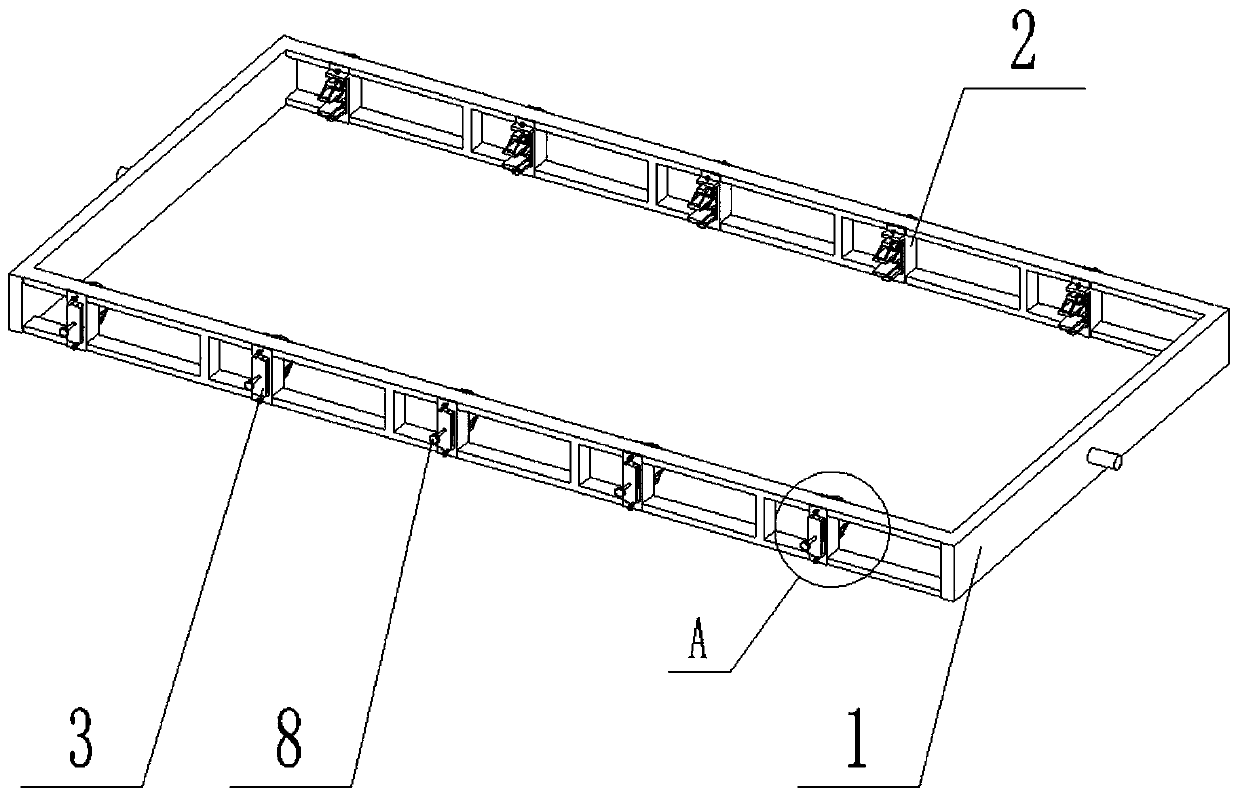

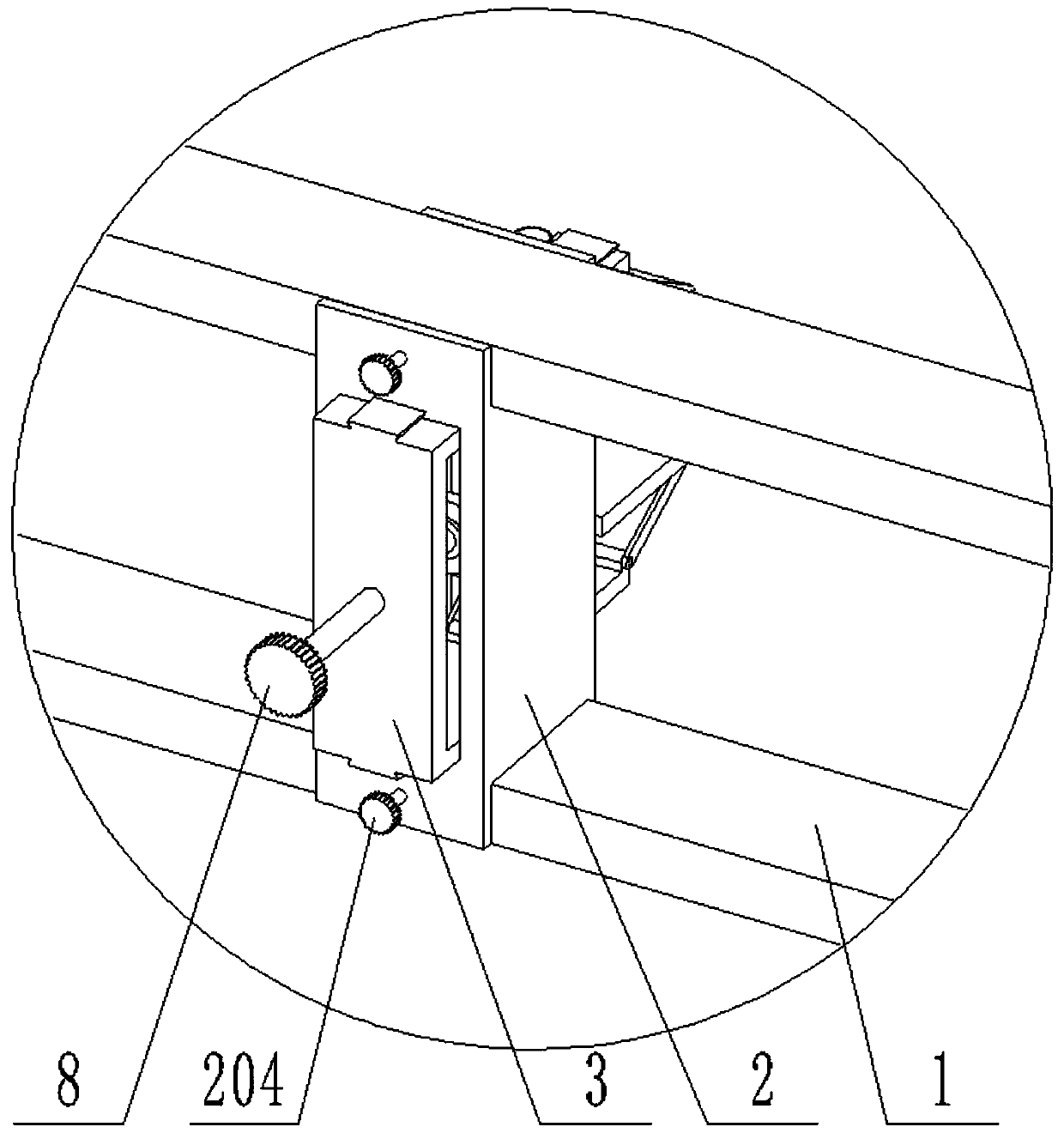

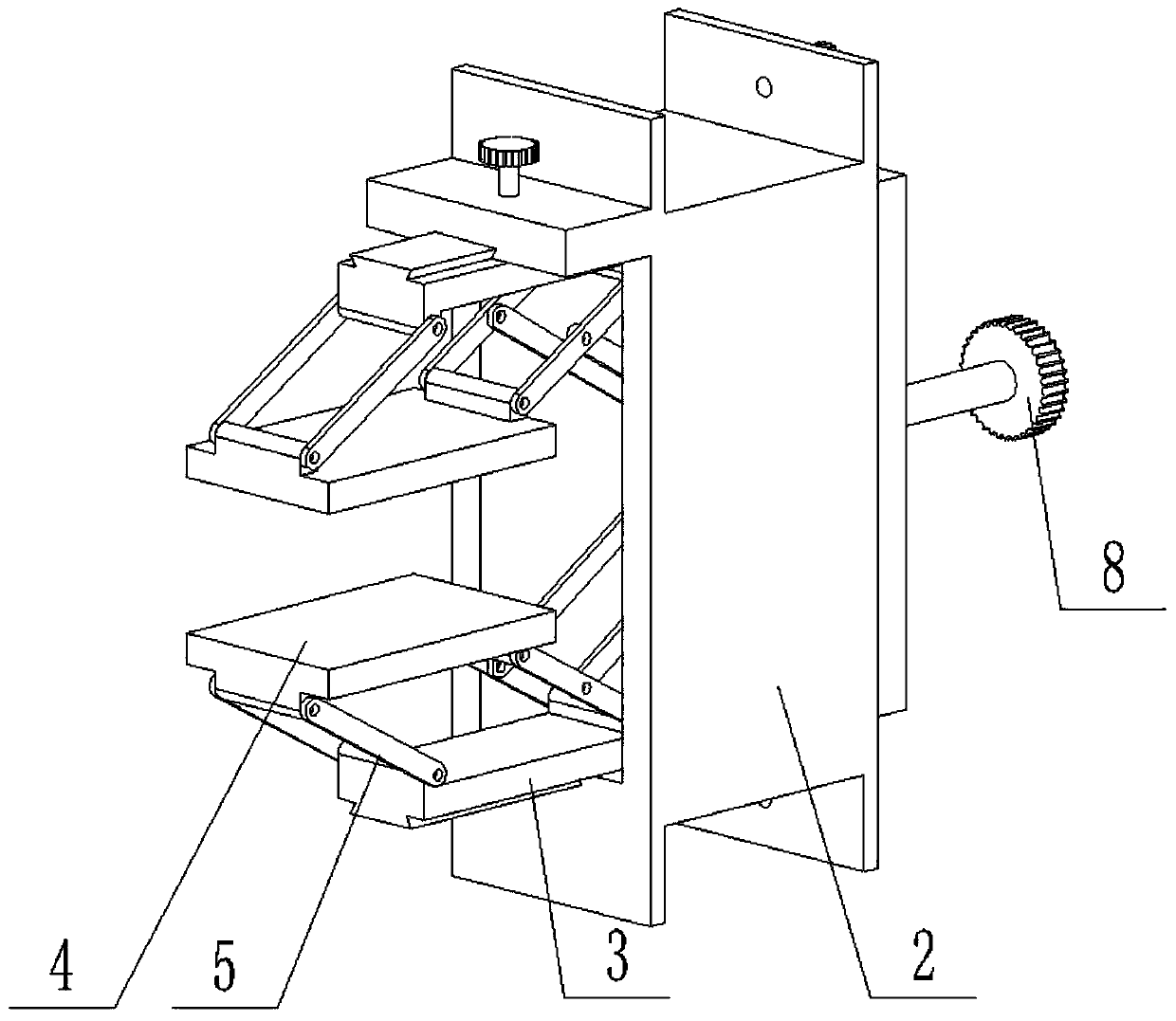

[0029] as attached figure 1 To attach Figure 7 Shown:

[0030] The invention provides a welding fixture for an overturned bracket, which includes an overturned bracket 1, a sliding seat 2, a dovetail groove 201, a sliding groove 202, a telescopic fixing bolt 203, a sliding fixing bolt 204, a telescopic plate 3, a clamping block 4, a swing rod 5, Tightening rod 6, tensioning block 7 and locking block 8; the front and rear end surfaces of the flip support 1 are all slidably connected with a set of sliding seats 2; the inner sides of each group of sliding seats 2 are slidably connected with a set of Expansion plate 3; The expansion plate 3 is a C-shaped structure, and the inner sides of the upper and lower plates of the expansion plate 3 are hinged with two groups of the swing rods 5; Clamping block 4; the middle hinge of the rightmost group of swing rods 5 is connected with a group of said tension rods 6; the right end surface of said telescopic plate 3 is threadedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com