Microwave ambient temperature wet oxidation wastewater advanced treatment method

A wet oxidation and advanced treatment technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of harsh reaction conditions and high energy consumption, reduce load and ensure work efficiency , Improve the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

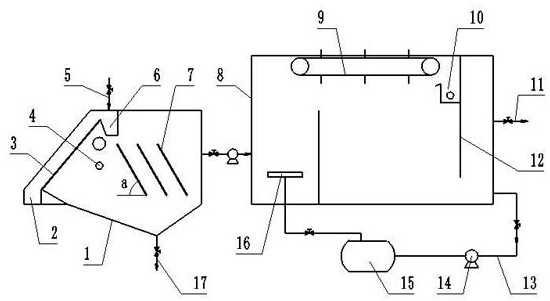

[0025] like figure 1 The shown kind of pretreatment air flotation device includes an air flotation box 8, the air flotation box 8 has an air flotation contact area and a separation area, and a dissolved air releaser 16 is installed in the air flotation contact area, and the dissolved air releaser 16 passes through the trachea. Connected to the dissolved gas tank 15 . A slag scraper 9 is installed on the upper part of the air flotation box 8. A slag discharge groove 10 is installed in front of the slag scraper 9, and a drainage guide plate 12 is installed in the air flotation box 8 below the slag discharge groove 10, and the drainage guides A water flow channel is provided between the plate 12 and the bottom plate of the air flotation box 8 . The air flotation box 8 is provided with a drain pipe 11 and a return water pipe 13 connected to the dissolved air tank 15 , and a circulating pump 14 is installed on the return water pipe 13 .

[0026] The water inlet of the air flotati...

Embodiment 2

[0036] Embodiment 2——Microwave normal temperature wet oxidation wastewater advanced treatment method

[0037] The difference between this embodiment and Embodiment 1 is:

[0038] figure 1 The inclination angle a of the sedimentation inclined plate 7 in the pretreatment air flotation device is 65 degrees; other features are the same as those in Example 1.

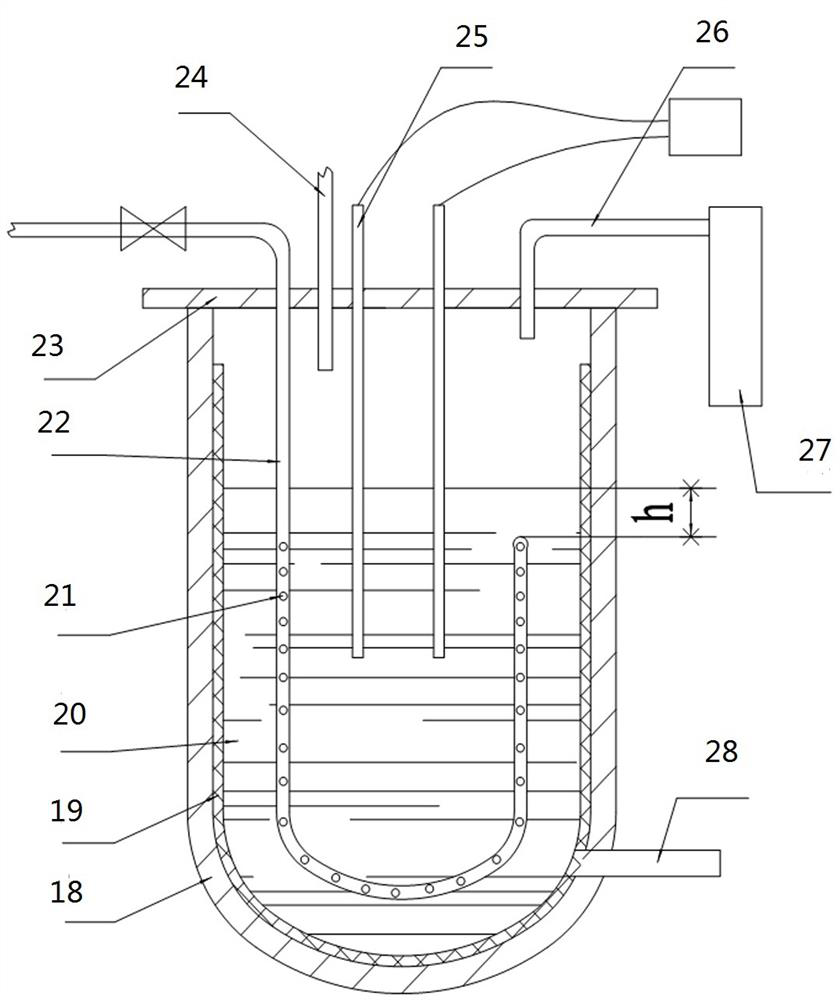

[0039] figure 2 In the microwave oxidation reactor, the end of the air inlet pipe below the liquid level in the reactor was 100 mm away from the liquid level in the reactor, and the diameter of the micropore was 6 mm; other features were the same as in Example 1.

[0040] With maleic anhydride wastewater as the wastewater to be treated, the method of the present invention is used to process:

[0041] A. Remove the suspended solids contained in the wastewater to be treated by using the above-mentioned pretreatment air flotation device:

[0042] B. Put the waste water after removing the suspended matter in step A into a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com