Arrangement of strain gauges and bridge connection method of a measurement-while-drilling device

A technology of measurement while drilling and layout method, which is applied in the direction of measuring device, electromagnetic measuring device, measurement, etc. It can solve the problems that bending moment parameters cannot be measured and affect the accuracy of measurement, etc., and achieve the effect of ensuring accuracy and simplifying the measurement circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

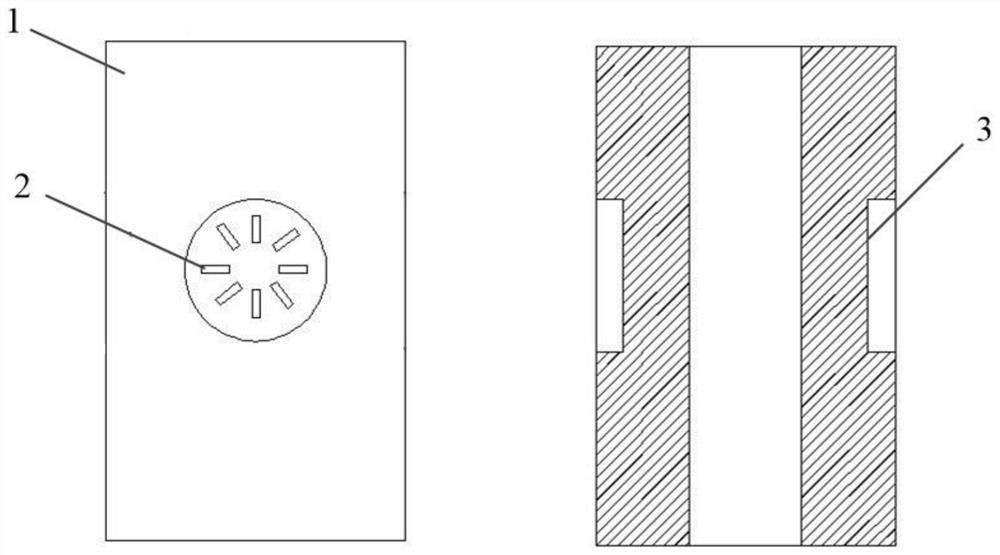

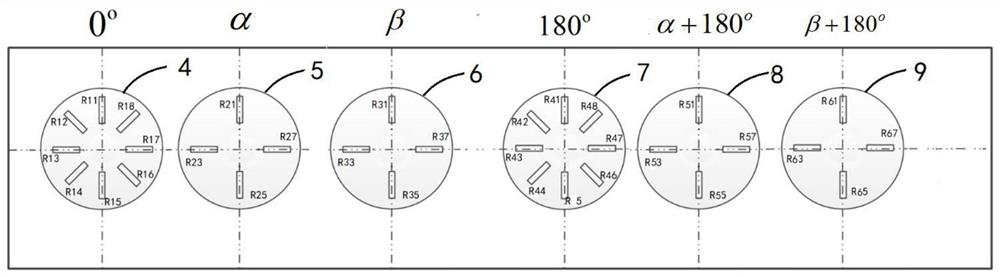

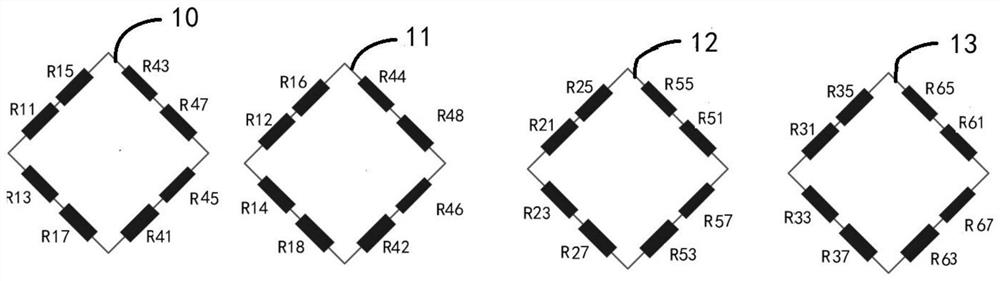

[0030] figure 1 Shown is the installation method of the measuring strain gage on the short drill collar. In order to make the strain gauge stick flat on the surface of the short drill collar, a circular plane needs to be milled on the surface of the short drill collar, and the strain gauge is pasted on this plane. A total of six planes are milled around the short drill collar, which are 0°, α, β°, 180°, α+180°, and β+180° in the circumferential direction (in this embodiment, α and β are respectively taken as values 60°, 120°). The specific pasting methods of strain gauges on these six planes are as follows: figure 2 shown. Among them, eight strain gauges are pasted on the two planes of 0° and 180°, each of which points to the center of the circular plane, and the interval between each strain gauge is 45 degrees. Among them, the four strain gauges parallel and per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com