An ultrasonic probe operating device with a pressure sensor

A pressure sensor and operating device technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve probe wear, affect detection accuracy, and cannot be accurately grasped Apply pressure and other issues to achieve the effect of simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

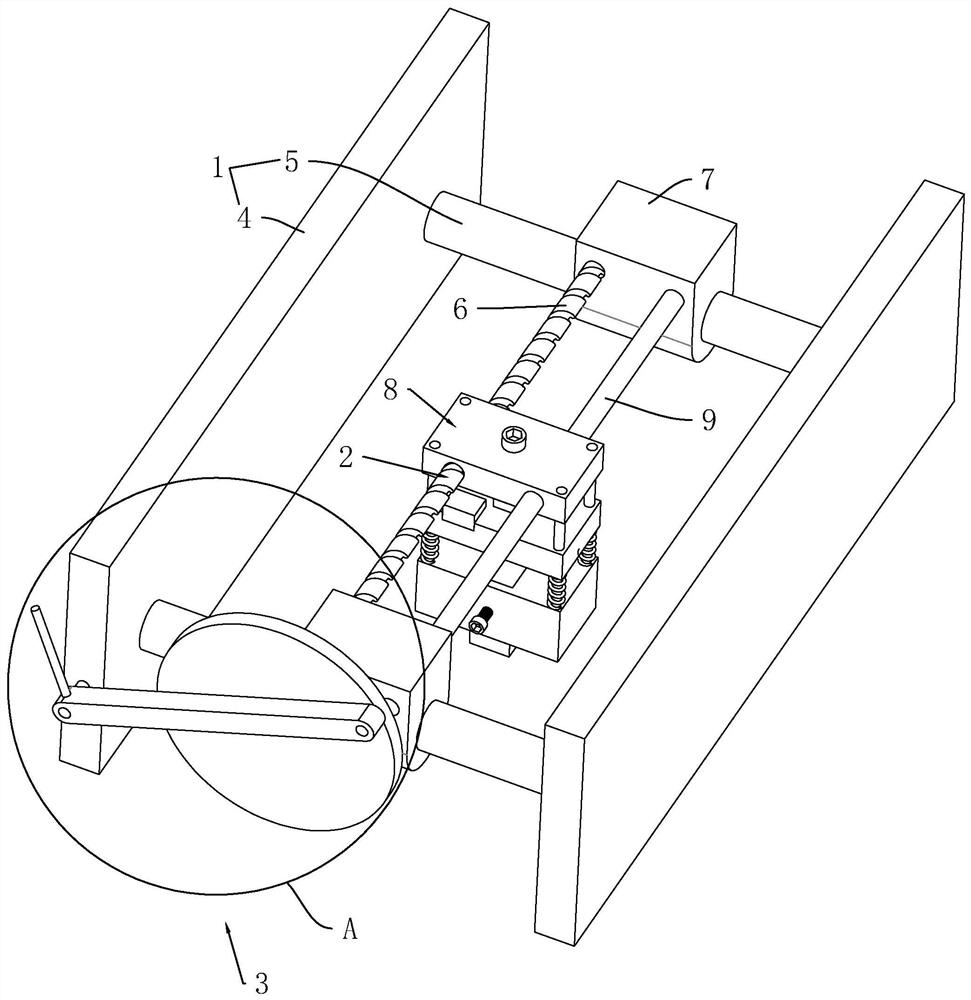

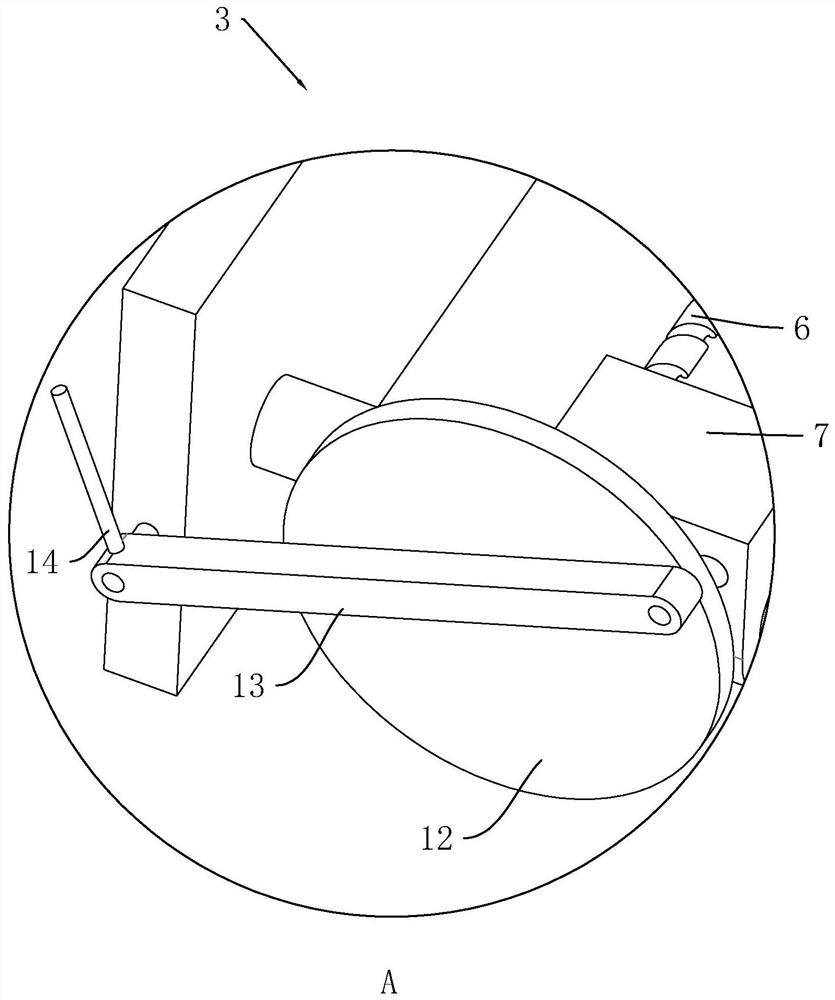

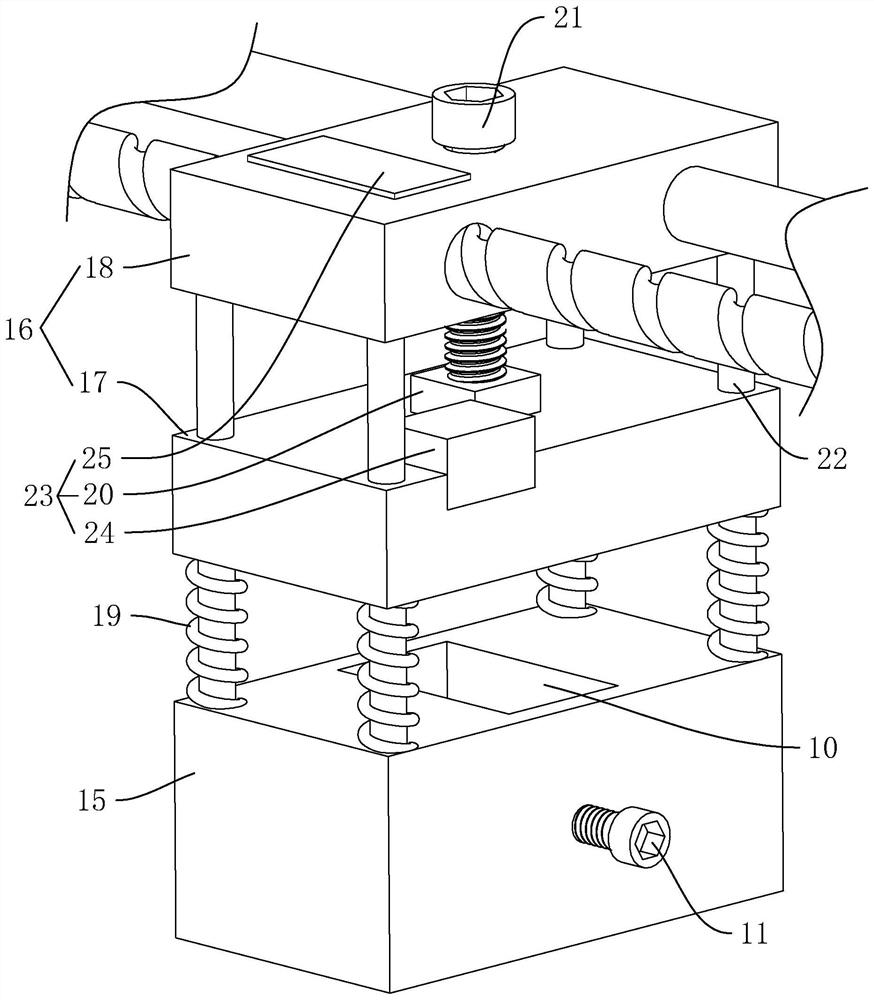

[0036] Embodiment: a kind of ultrasonic probe operating device with pressure sensor, such as figure 1 As shown, it includes a frame 1, a sliding structure 2, a driving structure 3 and a probe base 8. The probe base 8 is used to install the probe, the probe base 8 is slidably connected to the sliding structure 2, the sliding structure 2 is slidably connected to the frame 1, and the driving structure 3 drives the sliding structure 2 to slide, thereby driving the probe to slide.

[0037] Such as figure 1 As shown, the frame 1 includes two side plates 4 and two sliding bars 5, the two side plates 4 are vertically arranged and both are parallel, and the two sliding bars 5 are horizontally fixedly connected to the two side plates 4 between, and the sliding rods 5 are parallel to each other.

[0038] Such as figure 1 As shown, the sliding structure 2 includes a threaded rod 6 , a sliding seat 7 and a guide rod 9 . There are two sliding seats 7 and they are sleeved on two guide ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com