A production process of a stator assembly and its acoustic wave motor

A production process and component technology, which is applied to the production process of stator components and the field of acoustic wave motors, can solve the problems affecting the performance of stator components, low winding efficiency of acoustic wave motors, poor coils, etc., so as to achieve high electromagnetic conversion efficiency and improve winding efficiency. , The effect of reducing the difficulty of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

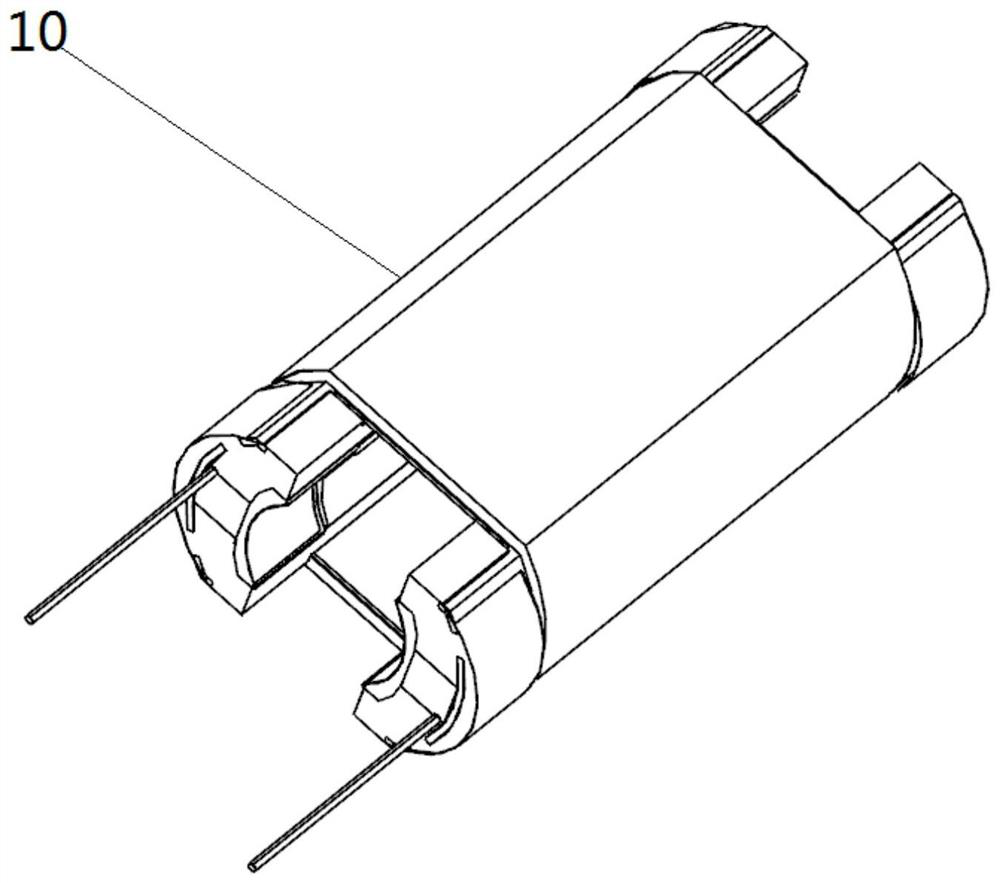

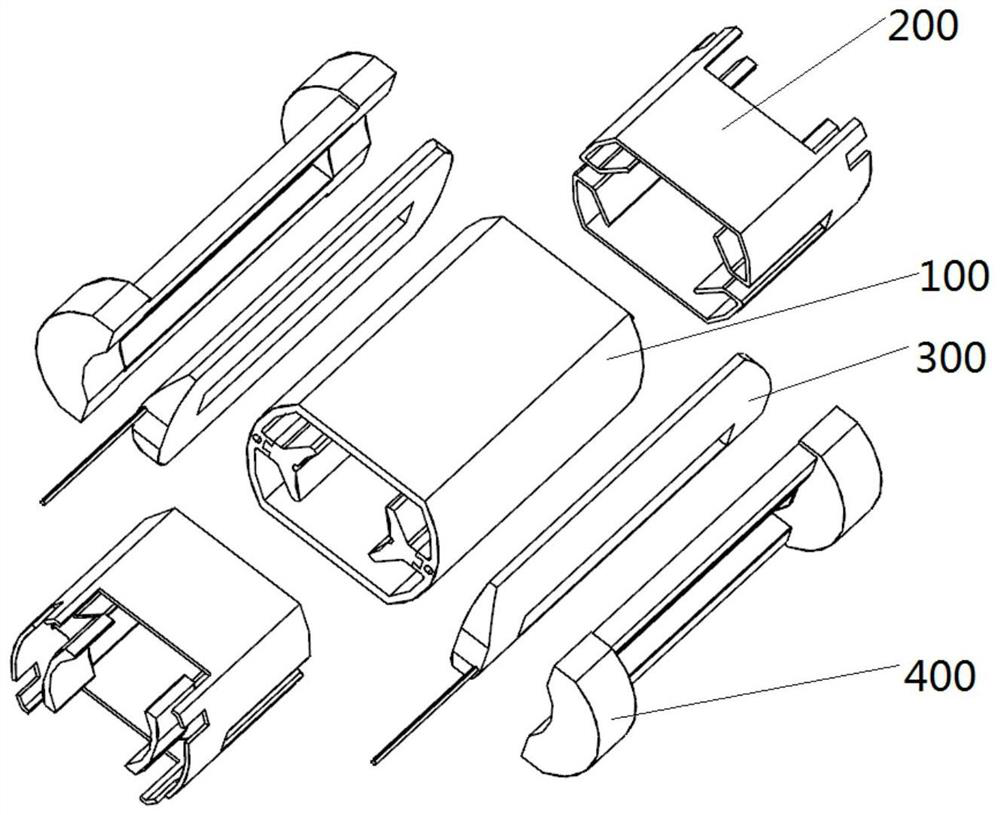

[0043] A stator assembly production process, see Figure 1 to Figure 12 , including the following steps:

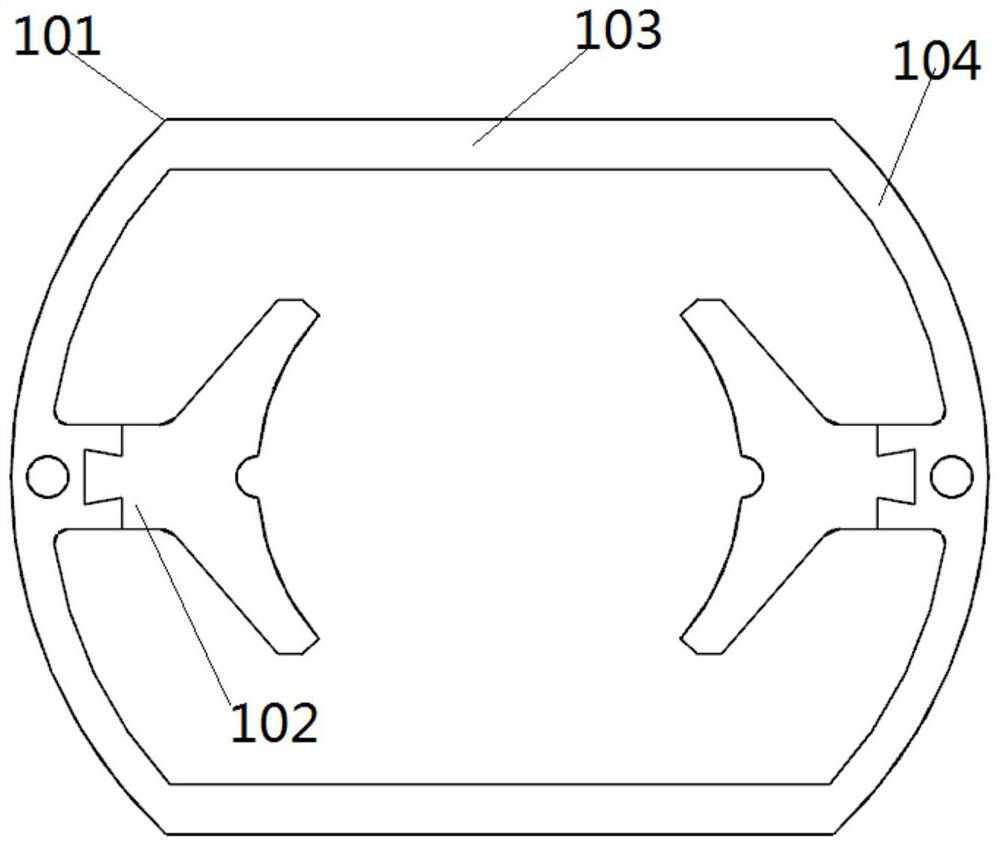

[0044] Step 1, fixing the iron core outer ring 101, the iron core outer ring 101 is in a closed ring shape, and the iron core outer ring 101 includes a horizontal plane 103 and an arc surface 104;

[0045] Step 2, the iron core teeth 102 are set on the inner side of the iron core outer ring 101, the iron core teeth 102 are arranged symmetrically along the diameter direction of the iron core outer ring 101, and the iron core teeth 102 are arranged symmetrically on the arc surface of the iron core outer ring 101;

[0046] Step 3, fixing the bracket 200, the bracket 200 is fitted with the iron core outer ring 101, and the bracket 200 is provided with a first limiting part 201 for clamping the iron core outer ring 101 and a notch part 202 for fixing the coil;

[0047] Step 4, use the wire winding jig 900 to wind the wire, and the coil 300 is wound in the notch 202 of the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com