Full-automatic equipment for producing varnish and production method of high-gloss and high-abrasion varnish

A fully automated equipment, varnish technology, applied in chemical instruments and methods, chemical/physical processes, mixers with rotary stirring devices, etc. Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

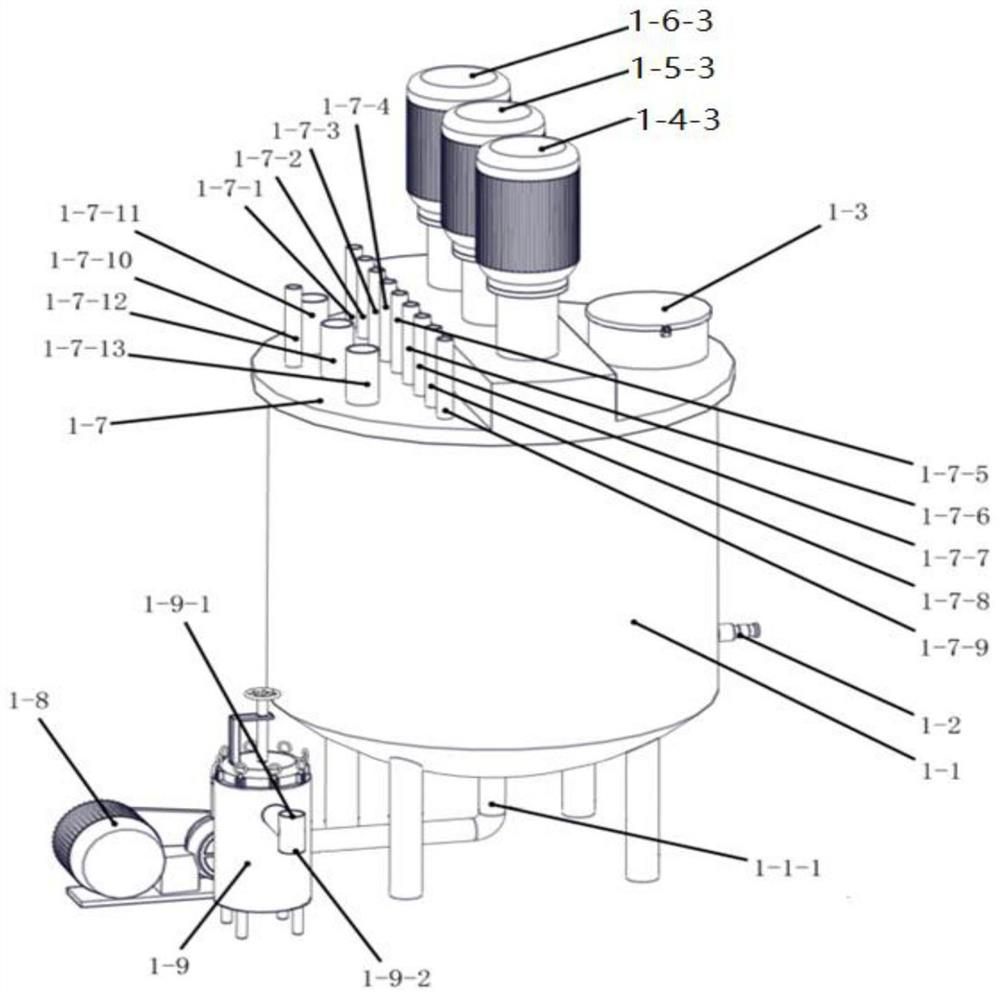

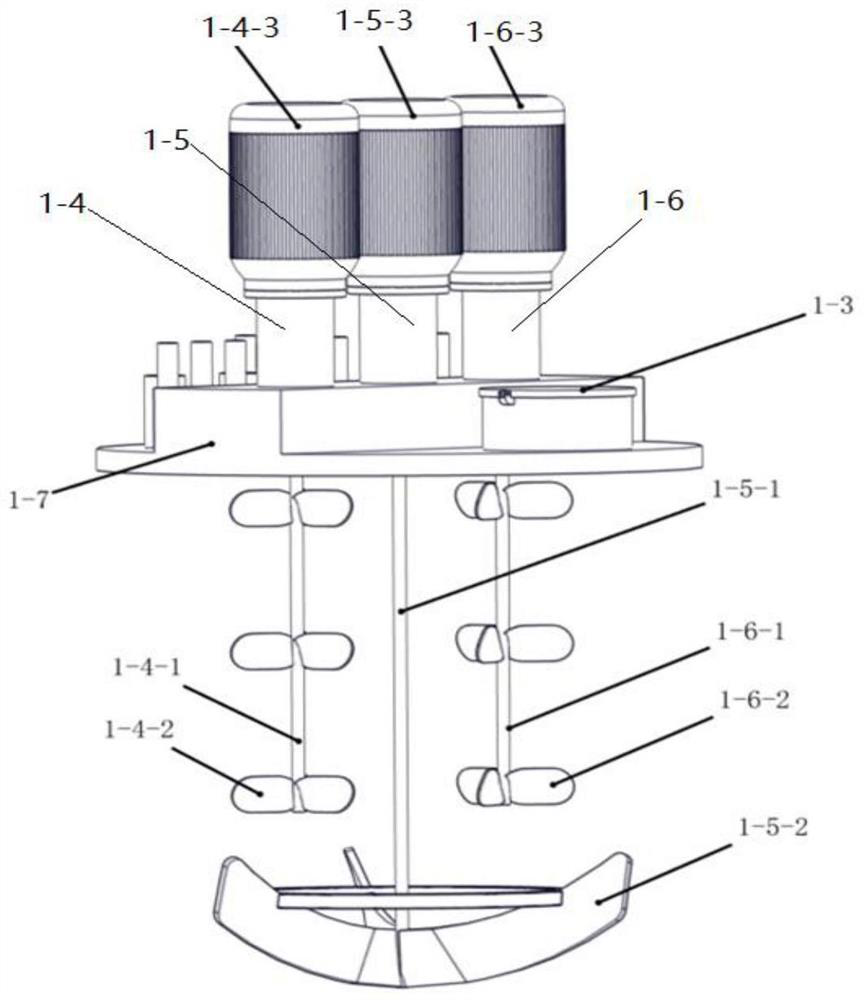

[0068] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

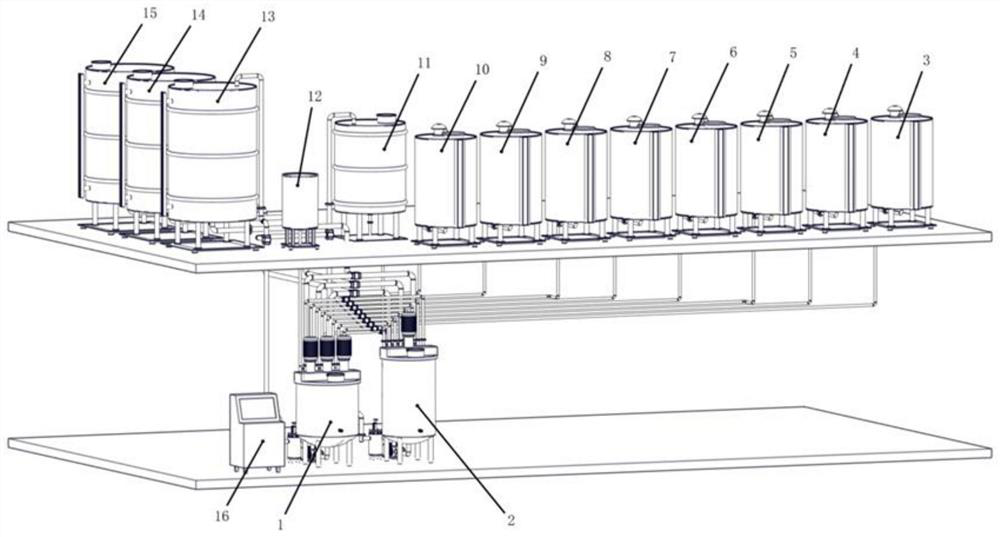

[0069] A kind of fully automatic equipment of producing varnish of the present invention, as figure 1 As shown, including stirred tank A1, stirred tank B2, water-based additive No. I tank 3, water-based additive No. II tank 4, water-based additive No. III tank 5, water-based additive No. IV tank 6, and water-based additive No. V tank 7. Water-based additive VI tank 8, water-based additive VII tank 9, water-based additive VIII tank 10, waste water circulation treatment tank 11, solid resin tank 12, water-based resin liquid I tank 13, water-based resin liquid II Tank 14, water-based resin liquid III tank 15, console 16.

[0070] Among them, the stirring tank A1, the stirring tank B2 and the console 16 are on the same horizontal plane, No. 3 tank of water-based additive, No. 4 tank of water-based additive II, No. 5 tank of water-based additive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com