Uniform heating gas adsorption performance testing device and method

A technology of gas adsorption performance and testing device, applied in the direction of material absorption and weighing, etc., can solve the problems of temperature difference inside and outside the cylinder, single adsorption capacity representation, etc., and achieve the effects of improved safety, accurate experimental data, and a wide range of heat source selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with embodiment.

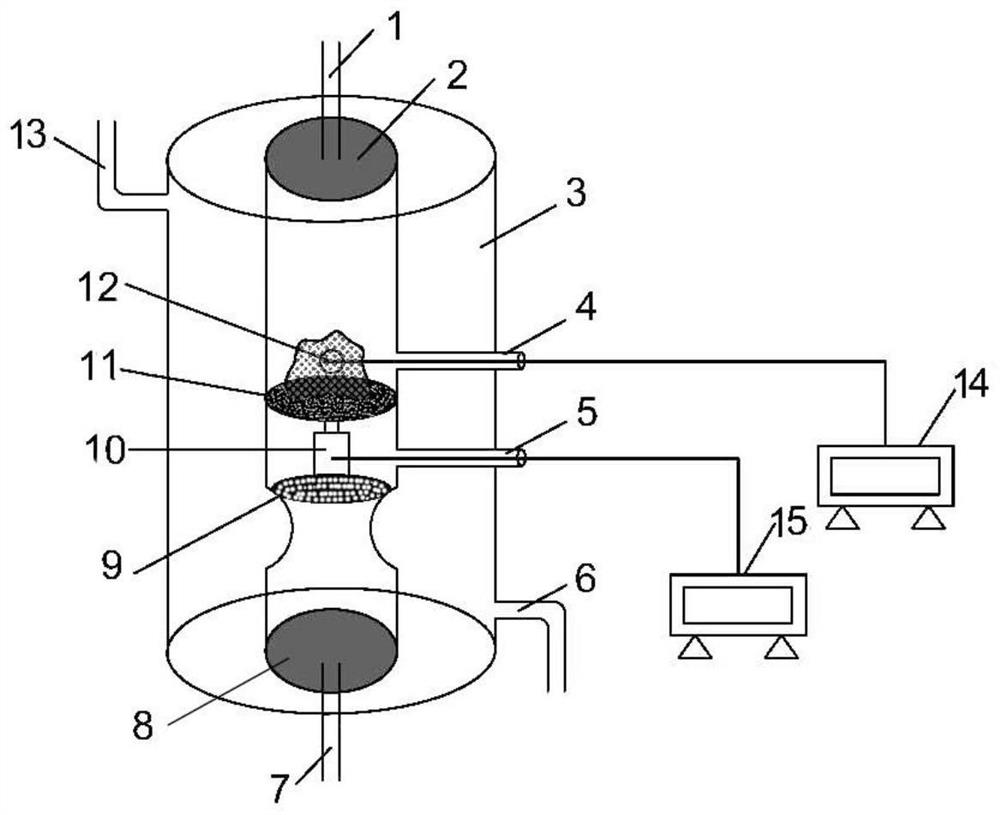

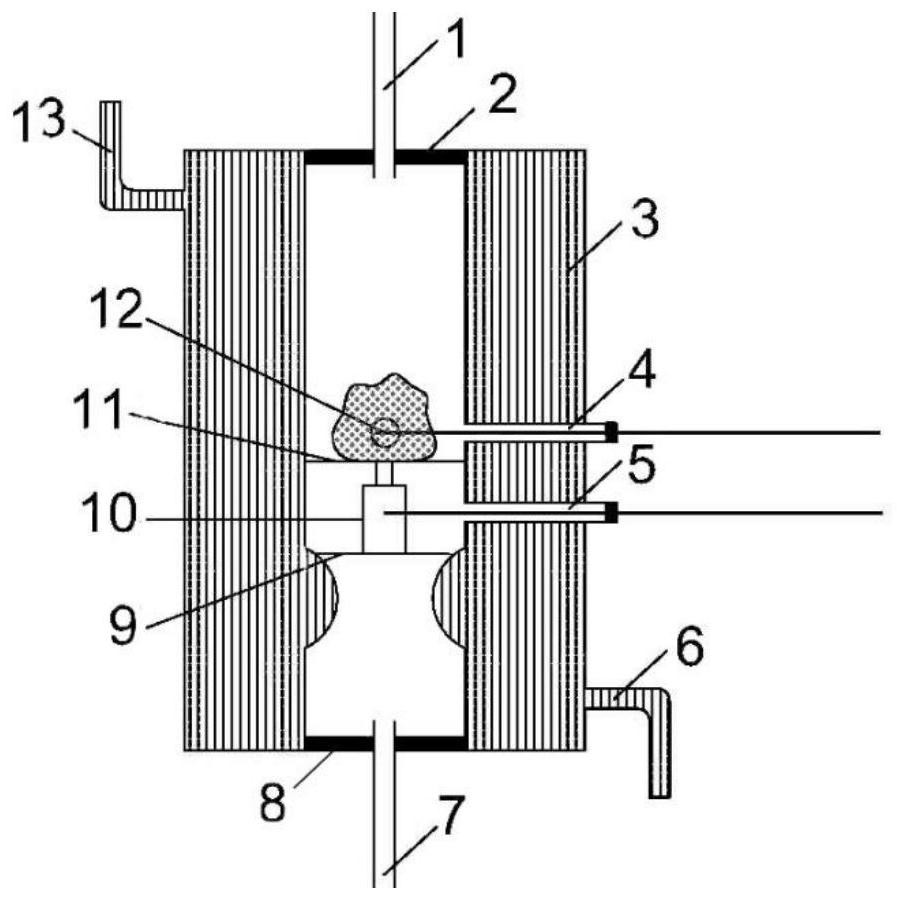

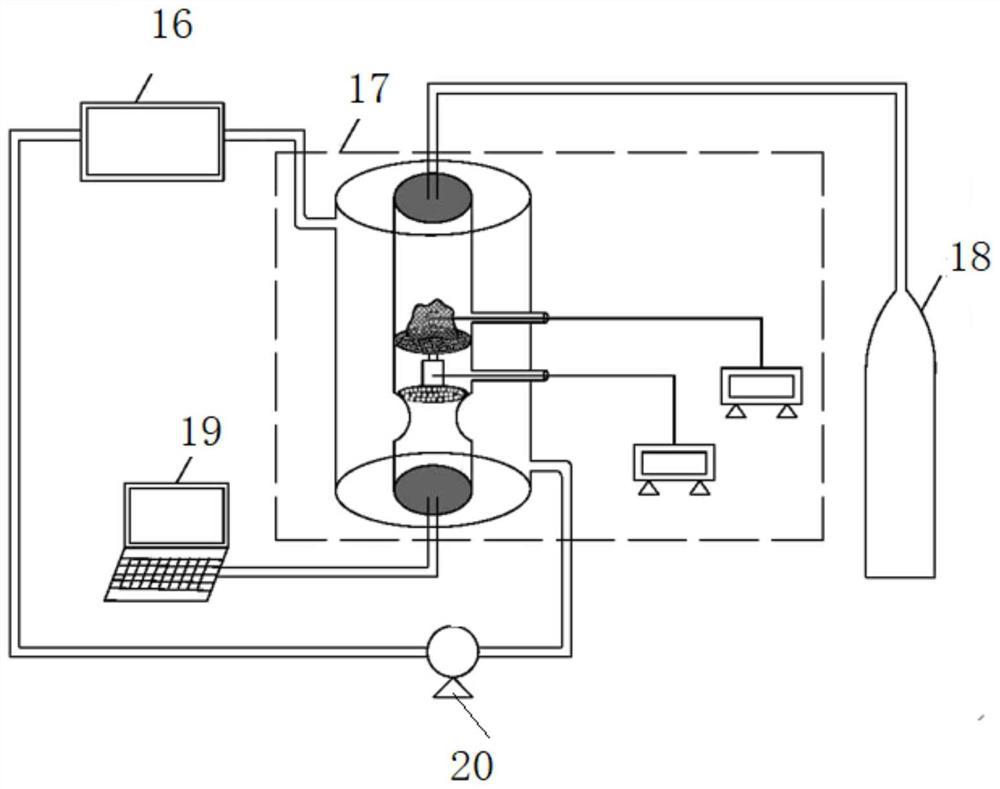

[0036] Such as figure 1 Shown: A uniformly heated fixed-bed gas adsorption device, specifically including a reactor, a stage, a heating system and a mass weighing system.

[0037] Further, the reactor is a double-layer quartz glass sleeve 3. Firstly, the thermal conductivity of the quartz glass is better. Secondly, the quartz glass has high heat resistance, and the short-term use temperature can reach 1400°C. Therefore, the choice of quartz glass as the reactor can not only reduce the temperature error and energy loss caused by the adsorption process, but also provide an equipment basis for the diversified selection of heat sources and adsorbents.

[0038] The structure of the sleeve 3 is as follows: the double-layer sleeve is a closed sleeve, the upper cover 2 and the lower cover 8 are perforated rubber plugs, the top and bottom side walls of the outer cylinder are designed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com