Automatic bubble cleaning system

A bubble cleaning, automatic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of reduced production efficiency, long wiping time, time-consuming and laborious, etc., to achieve production efficiency improvement, cleaning The effect of time reduction and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

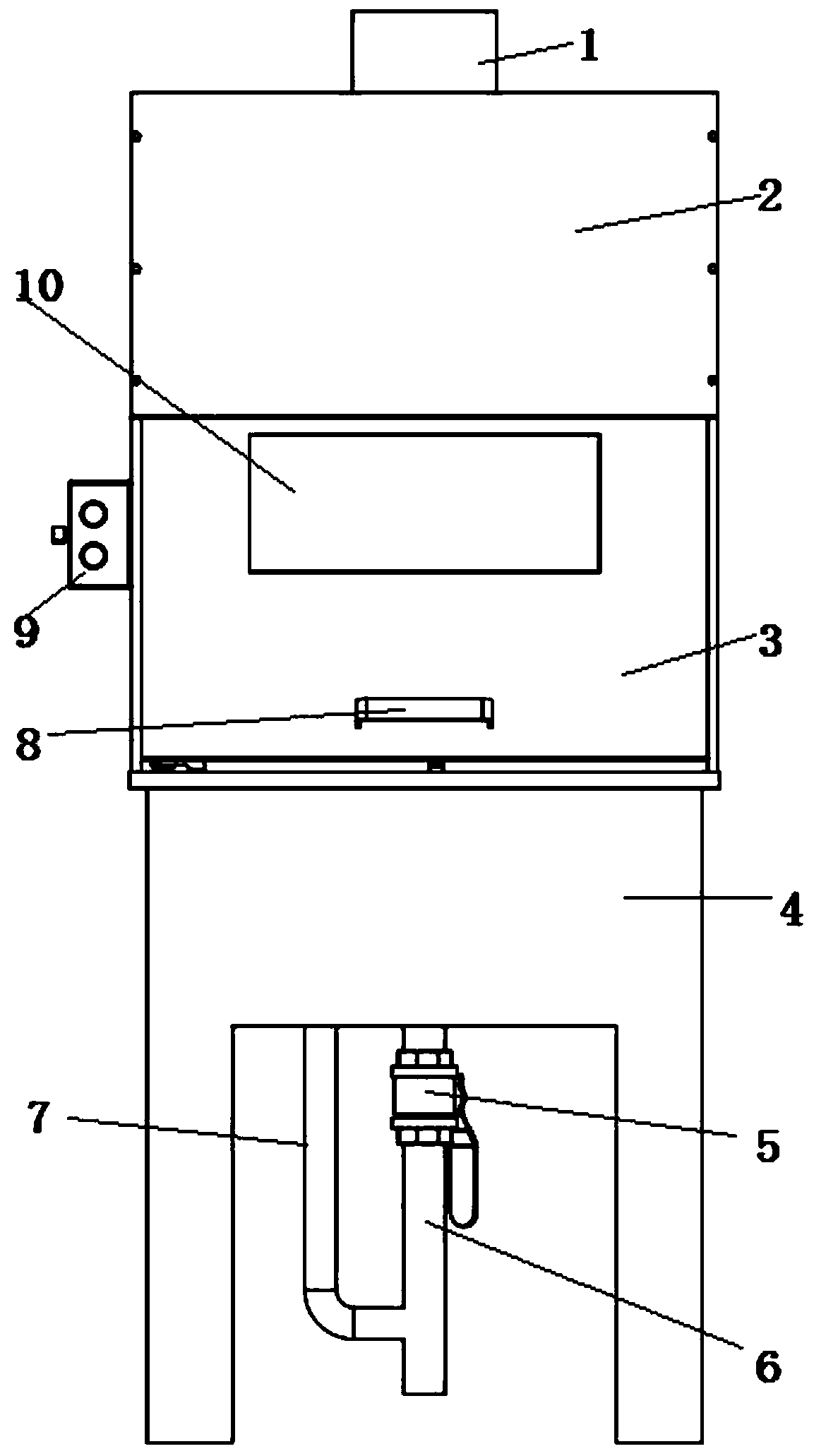

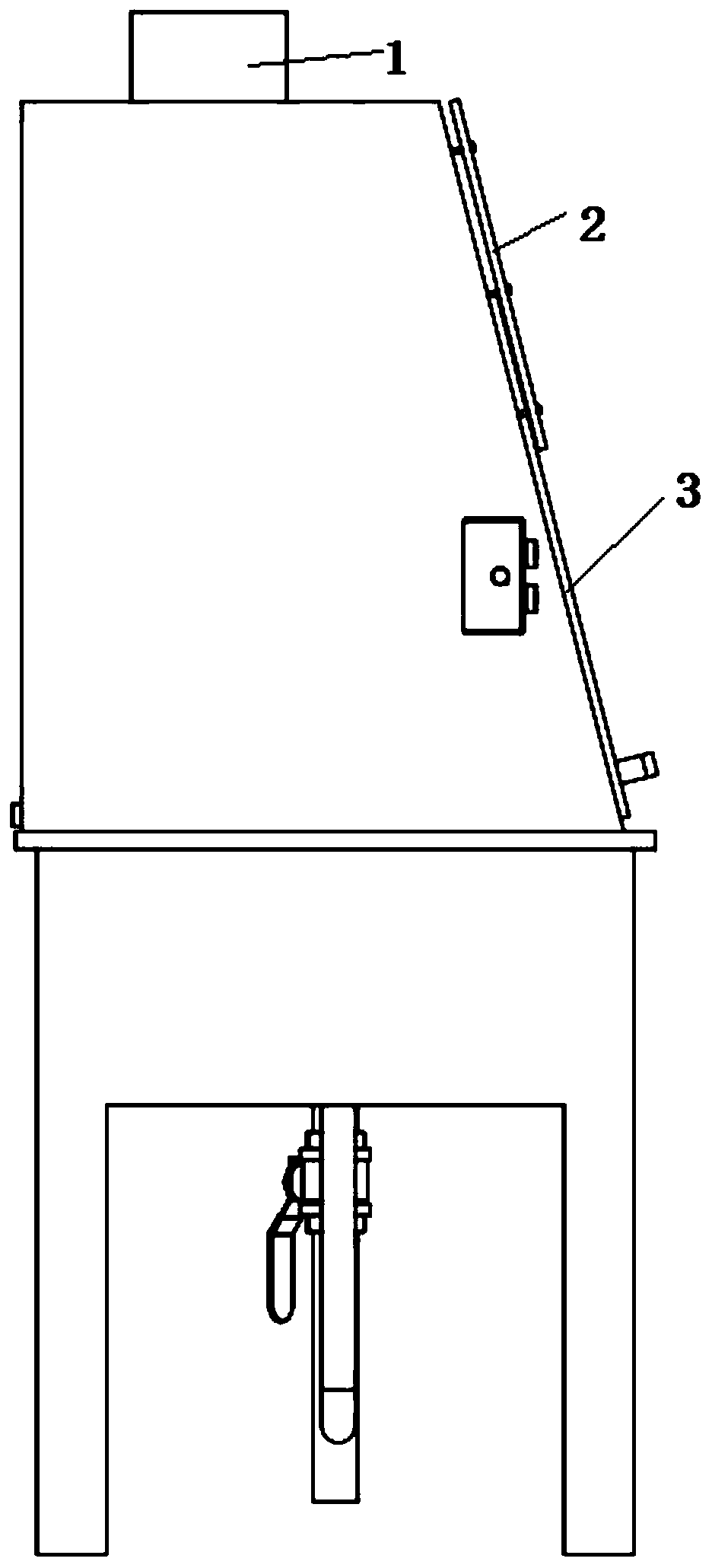

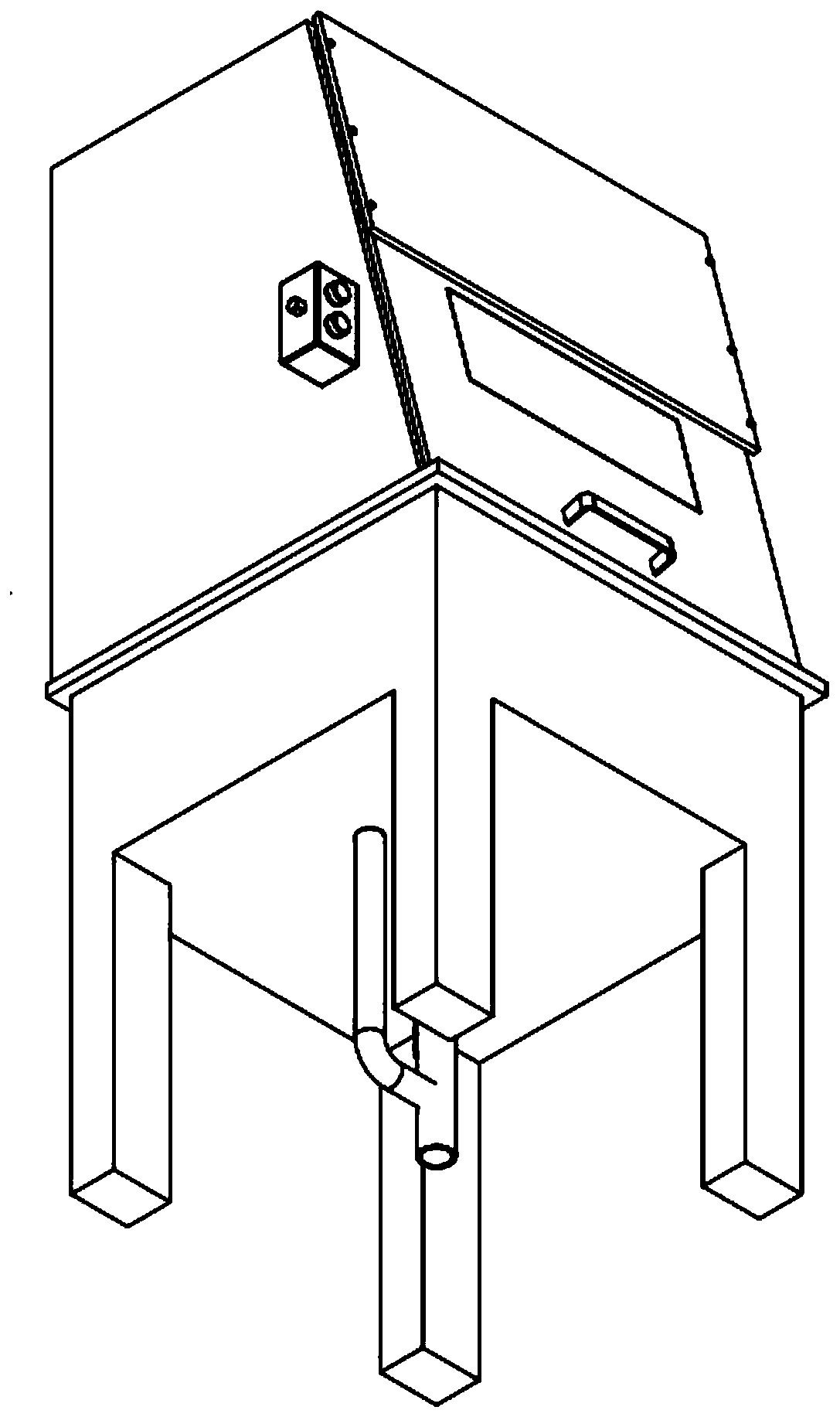

[0028] Such as Figure 1-9 As shown, the present embodiment provides an automatic air bubble cleaning system, comprising: an upper tank body and a lower tank body connected together, one side of the upper tank body is an inclined surface, and a baffle plate and an upper pull-up are installed on the inclined surface Plate; cleaning equipment and overflow device are provided in the lower tank body, the cleaning equipment includes air outlet pipe, cleaning plate, support plate, multiple rows of cleaning holes are arranged on the cleaning plate, and multiple supports are distributed on the bottom surface of the cleaning plate There are multiple passage holes on the support plate, and each row of passage holes on each support plate is on a horizontal line; multiple air outlet pipes are located in the corresponding passage holes, and the bottom surface of each air outlet pipe is provided with multiple air outlet holes The overflow device includes an overflow side plate and an overfl...

Embodiment 2

[0030] This embodiment provides a working method of an automatic air bubble cleaning system, and the specific steps of the method are as follows:

[0031] S1: Stand the four outriggers at the bottom of the lower tank on a flat ground;

[0032] S2: Connect the water inlet pipe to the tap water pipe to ensure that the water source of the tank is sufficient to achieve the effect of overflowing and continuous water;

[0033] S3: the air intake pipe is connected to the air source device, and the air intake pipe is provided with a regulating valve a;

[0034] S4: The PLC controller turns on the exhaust fan to ensure that the odor gas in the tank can flow away effectively;

[0035] S5: The PLC controller opens the regulating valve c, injects water into the lower tank body, and after the water in the lower tank body is filled to the height of the overflow port, the excess water flows out from the overflow port, flows through the overflow channel, and drains channel, which eventually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com