Manufacturing device and manufacturing method of composite electrolytic plate

An electrolytic plate and equipment technology, which is applied in the field of composite electrolytic plate production equipment, can solve problems such as poor alkali cleaning effect, easy peeling off of the coating, poor activation state of the thin steel plate surface, etc., to achieve the effect of ensuring flatness and benefiting electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

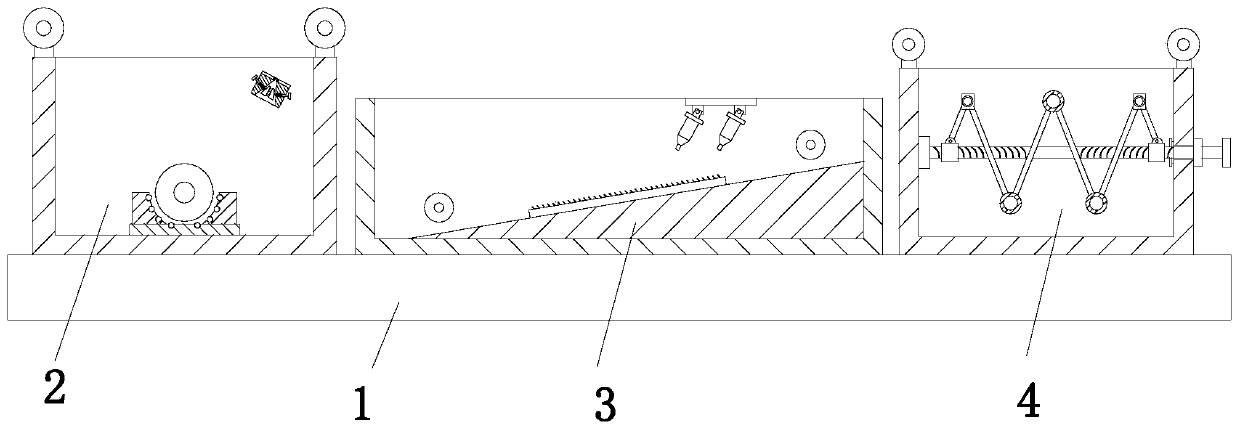

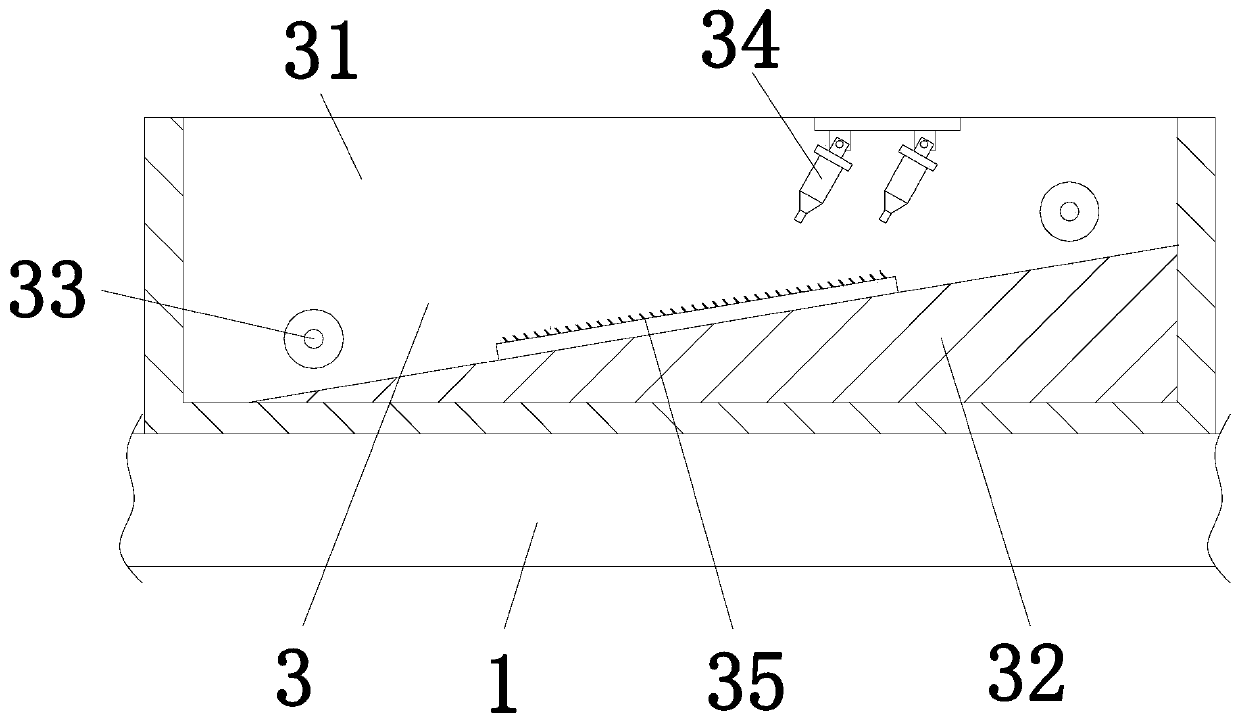

[0034] Such as Figure 1 to Figure 5 As shown, a composite electrolytic plate production equipment includes a base plate 1, an alkali cleaning device 2, a water washing device 3 and an acid pickling device 4. The base plate 1 is equipped with an alkali cleaning device 2 on the left side of the upper end, and the upper end of the base plate 1 is installed in the middle. There is a washing device 3, and a pickling device 4 is installed on the right side of the upper end of the bottom plate 1.

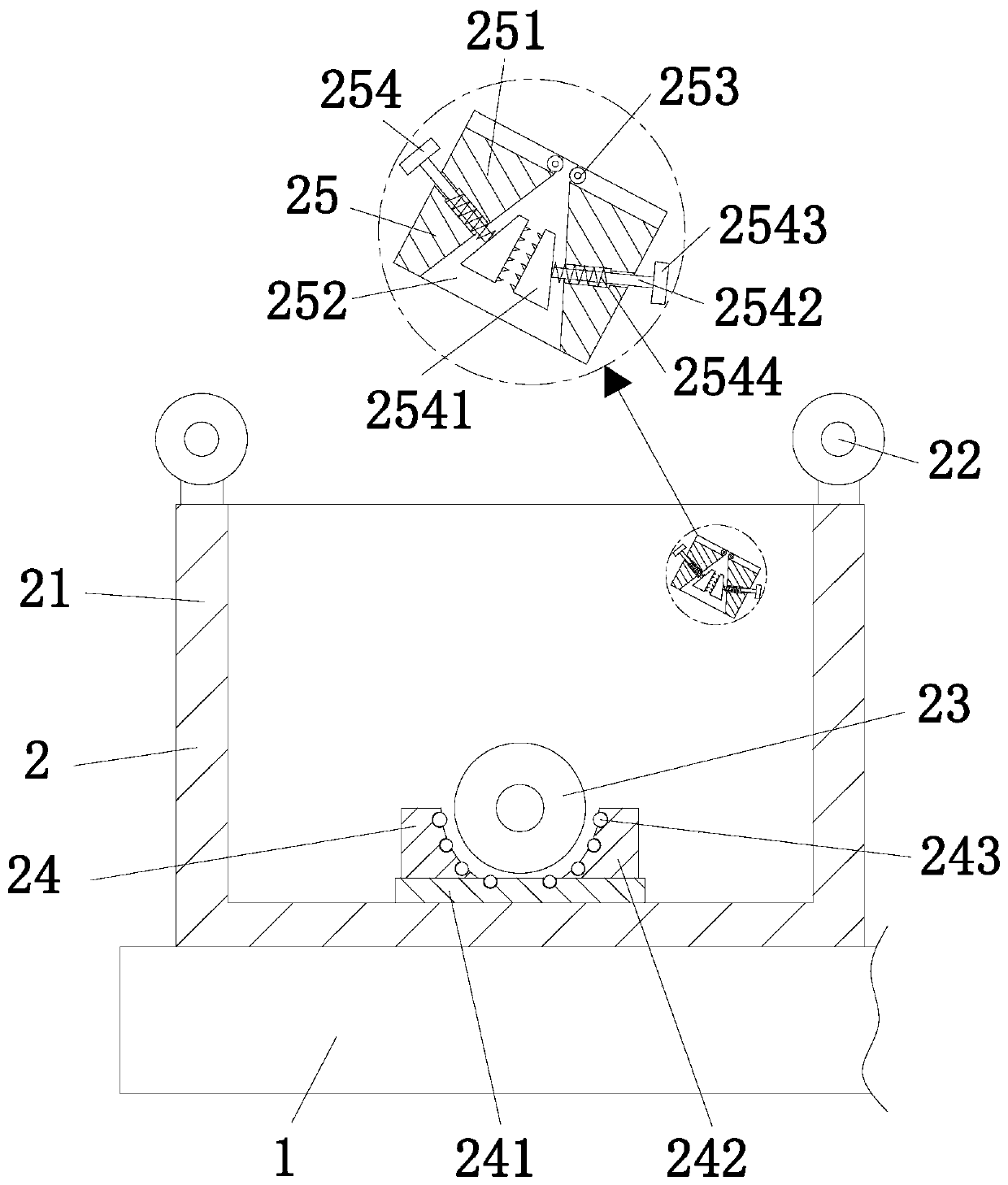

[0035] Described alkaline cleaning device 2 comprises alkaline cleaning tank 21, No. 1 guide roller 22, cleaning roller 23, cleaning frame 24 and scraping mechanism 25, and described alkaline cleaning tank 21 is installed on the left side of base plate 1 upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com