A continuous heating water heater

A continuous heating and water heater technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of slow hot water supply and unsatisfactory continuous use by users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

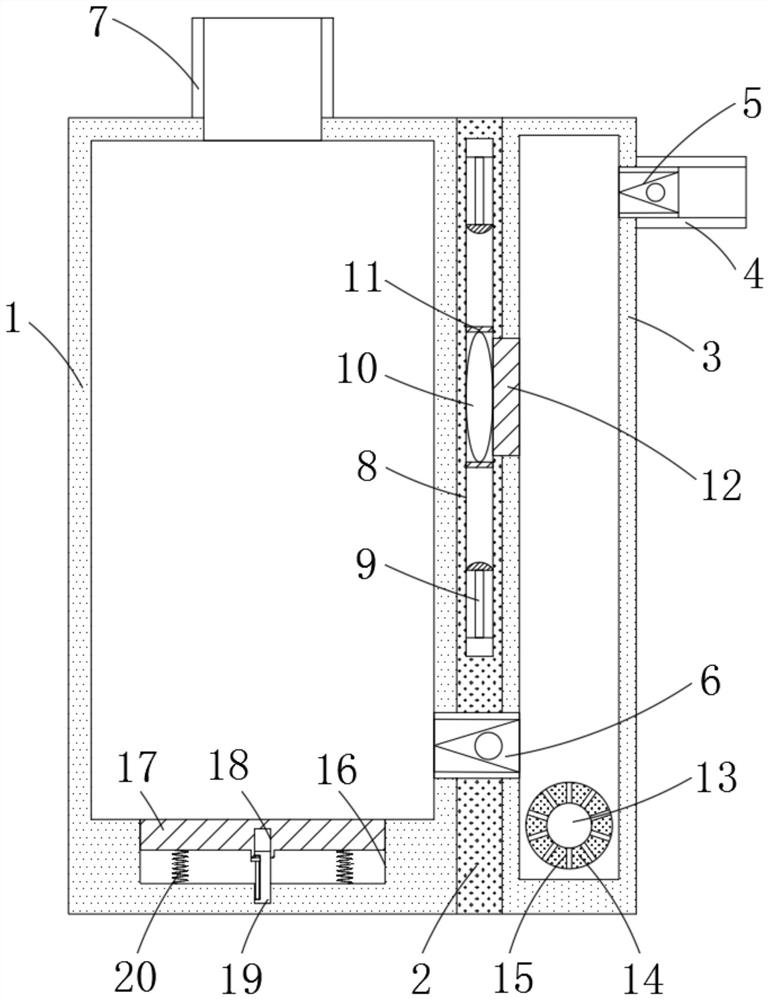

[0018] refer to figure 1 , a continuous heating water heater, comprising a hot water tank 1, an induction tank 2 and a heating tank 3, the two sides of the induction tank 2 are respectively welded to the hot water tank 1 and the heating tank 3, and the upper end of the heating tank 3 is connected through the side wall There is a water inlet pipe 4, the inner wall of the water inlet pipe 4 is glued with a water inlet valve 5, the inner wall of the lower end of the heating box 3 is penetrated and connected with a water supply valve 6, and the water supply valve 6 runs through the side walls of the induction box 2 and the hot water tank 1 to connect the heating box 3 with the hot water tank. The water tank 1 is connected, the upper end of the hot water tank 1 is connected with an outlet pipe 7, the bottom of the heating box 3 is welded with an electric heating rod 13, and the inside of the induction box 2 is provided with an induction chamber 8, and the inner walls of the upper an...

Embodiment 2

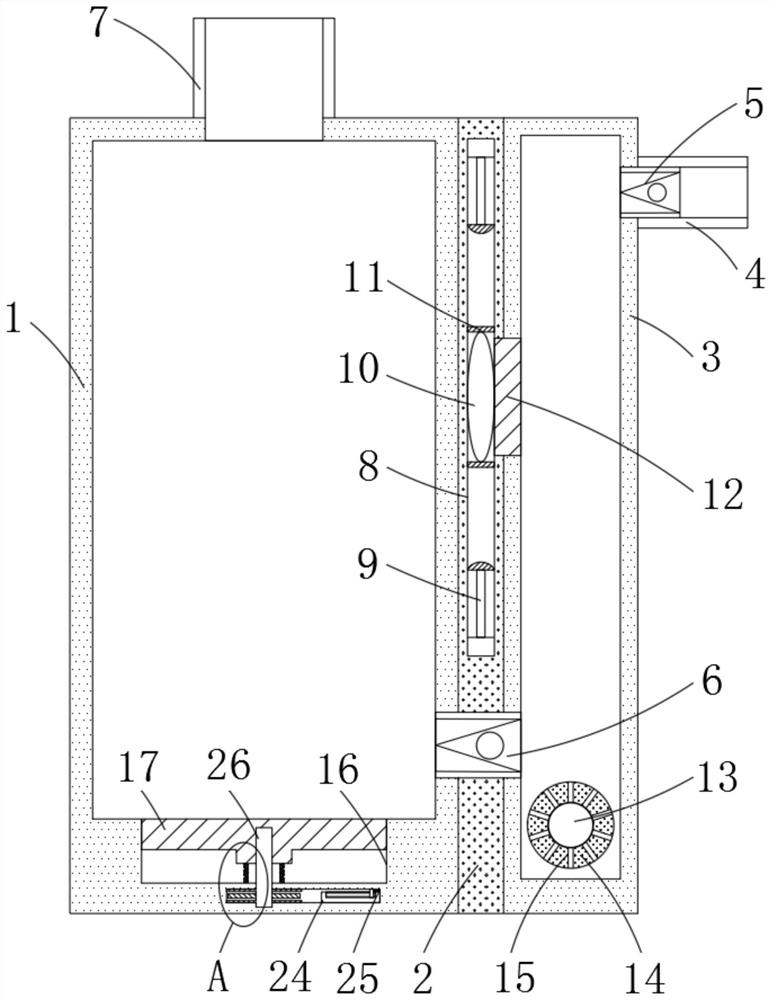

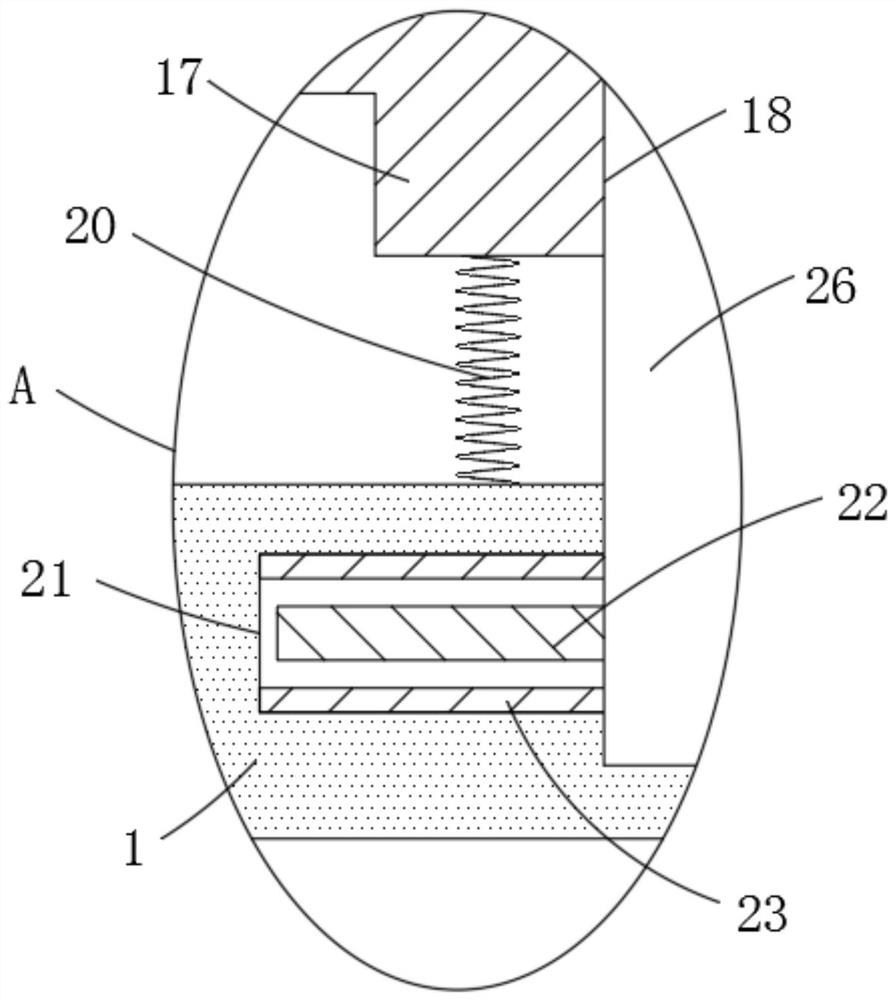

[0025] refer to Figure 2-3The difference between this embodiment and Embodiment 1 lies in the difference of the linkage device. The linkage device includes a linkage plate 17 and an indirect rheostat 24. The inner bottom of the hot water tank 1 is provided with a linkage groove 16, and the upper opening of the linkage groove 16 is glued with a layer of waterproof The film isolates the inner wall of the linkage groove 16 from the hot water inside the hot water tank 1 to ensure the existence of water pressure at both ends of the linkage plate 17. The inner wall of the linkage groove 16 is slidingly connected with the linkage plate 17, and the bottom of the linkage plate 17 is provided with linkage holes 18. The inner wall of the interlocking hole 18 is threadedly connected with the rotating shaft 26, and the thread lead angle of the threaded connection is greater than the equivalent friction angle of the screw pair, so that the rotation of the interlocking hole 18 and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com