Testing apparatus for special threaded oil casing tightness monitoring under dynamic load working condition

A test device and thread oil technology are applied in the direction of fluid tightness testing, measuring devices, liquid tightness measurement using liquid/vacuum degree, etc., which can solve the problem of inability to detect the change of contact stress on the thread and sealing contact surface, and the inability to To ensure the sealing effect of oil casing sealing surface contact stress, unable to judge whether the make-up is qualified, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention. In the description of the present invention, it should be understood that the terms "first", "second" and so on are only used for the purpose of description, and should not be understood as indicating or implying relative importance.

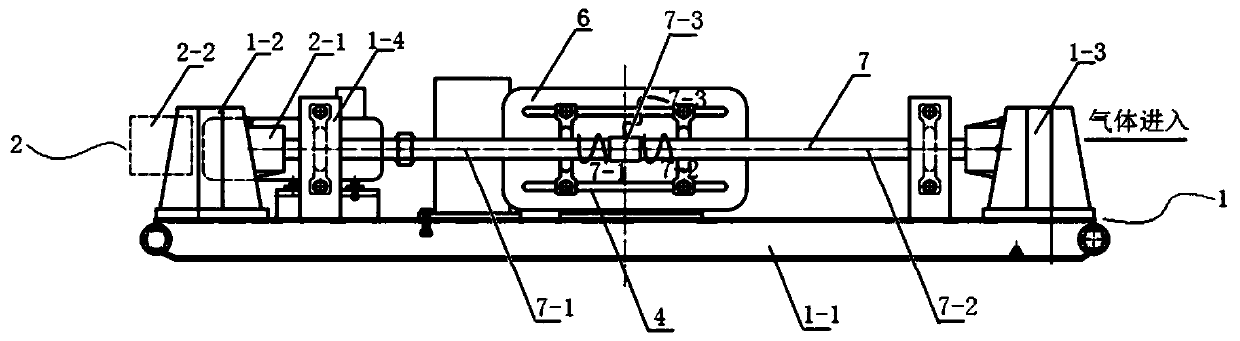

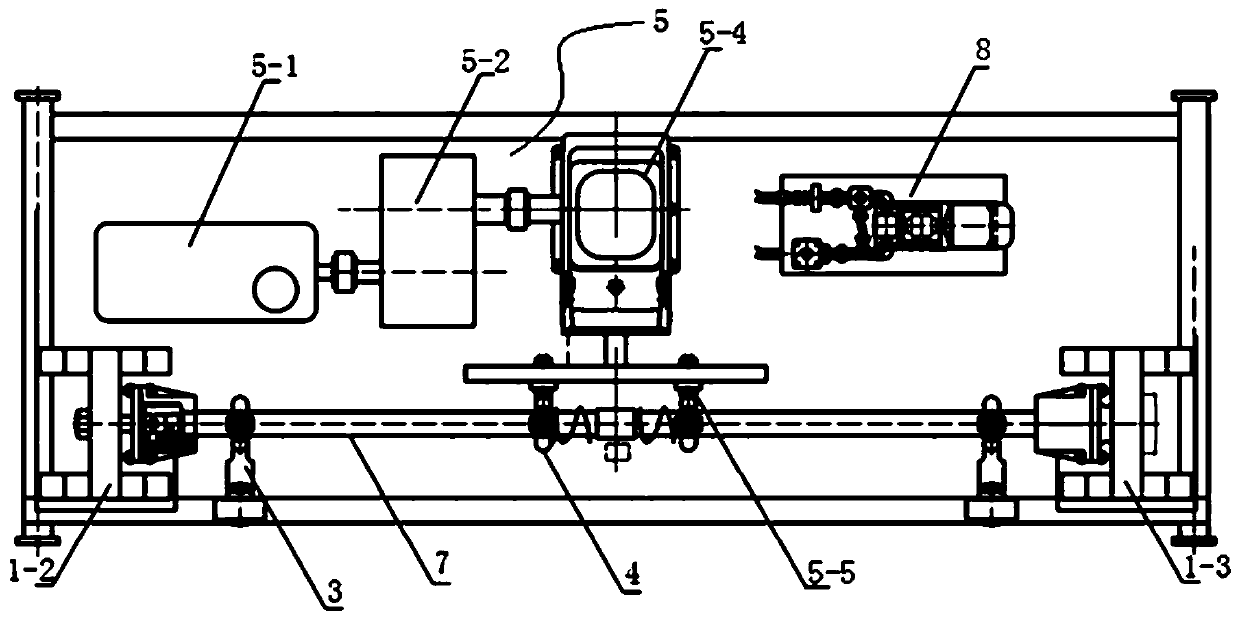

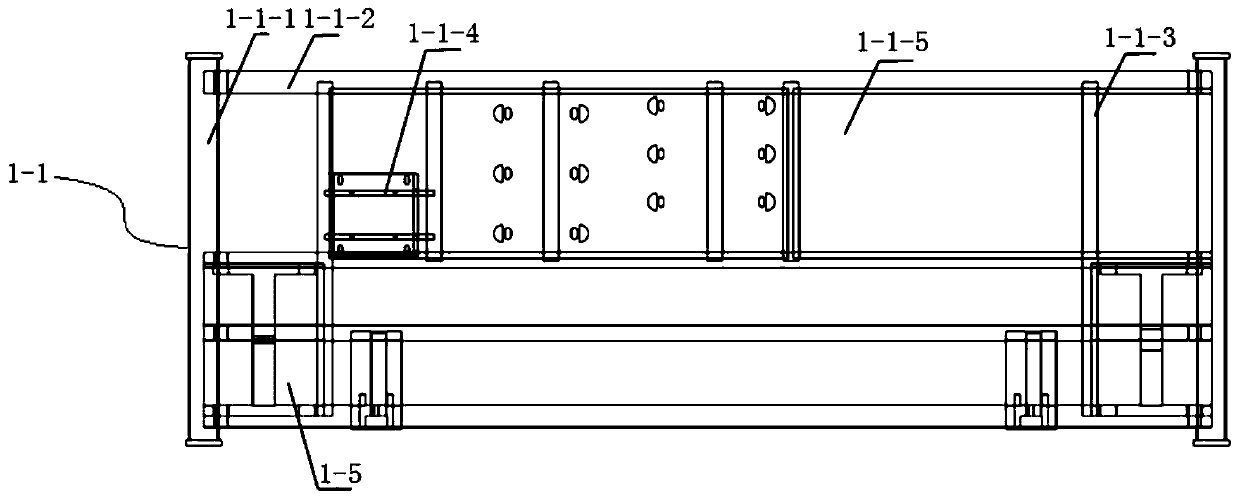

[0024] Such as figure 1 , figure 2 As shown, the test device for monitoring the tightness of special threaded oil casing under dynamic load conditions provided by the present invention includes a support 1, a hydraulic tension device 2, a first sample clamping device 3, and a second sample clamping device 4 , a vibration loading device 5, an adjustment plate 6, a first pressure sensor, a second pressure sensor, a frequency sensor, a displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com